Shovel fin ceramic PTC electric heater

An electric heater and ceramic technology, applied in the direction of the shape of the heating element, can solve the problems of product power attenuation, pressure drop, limited heat dissipation performance, etc., and achieve the effect of improving product life, reducing quantity and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

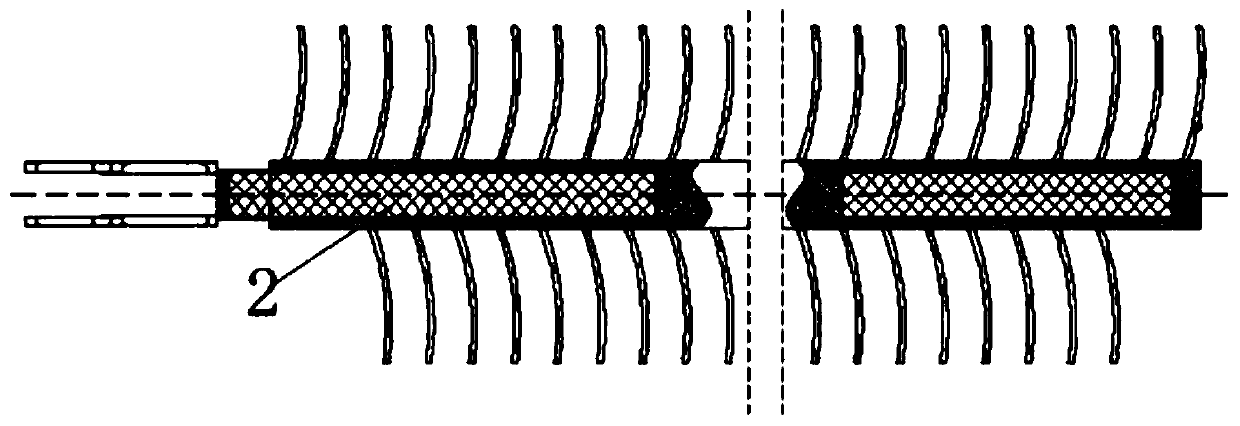

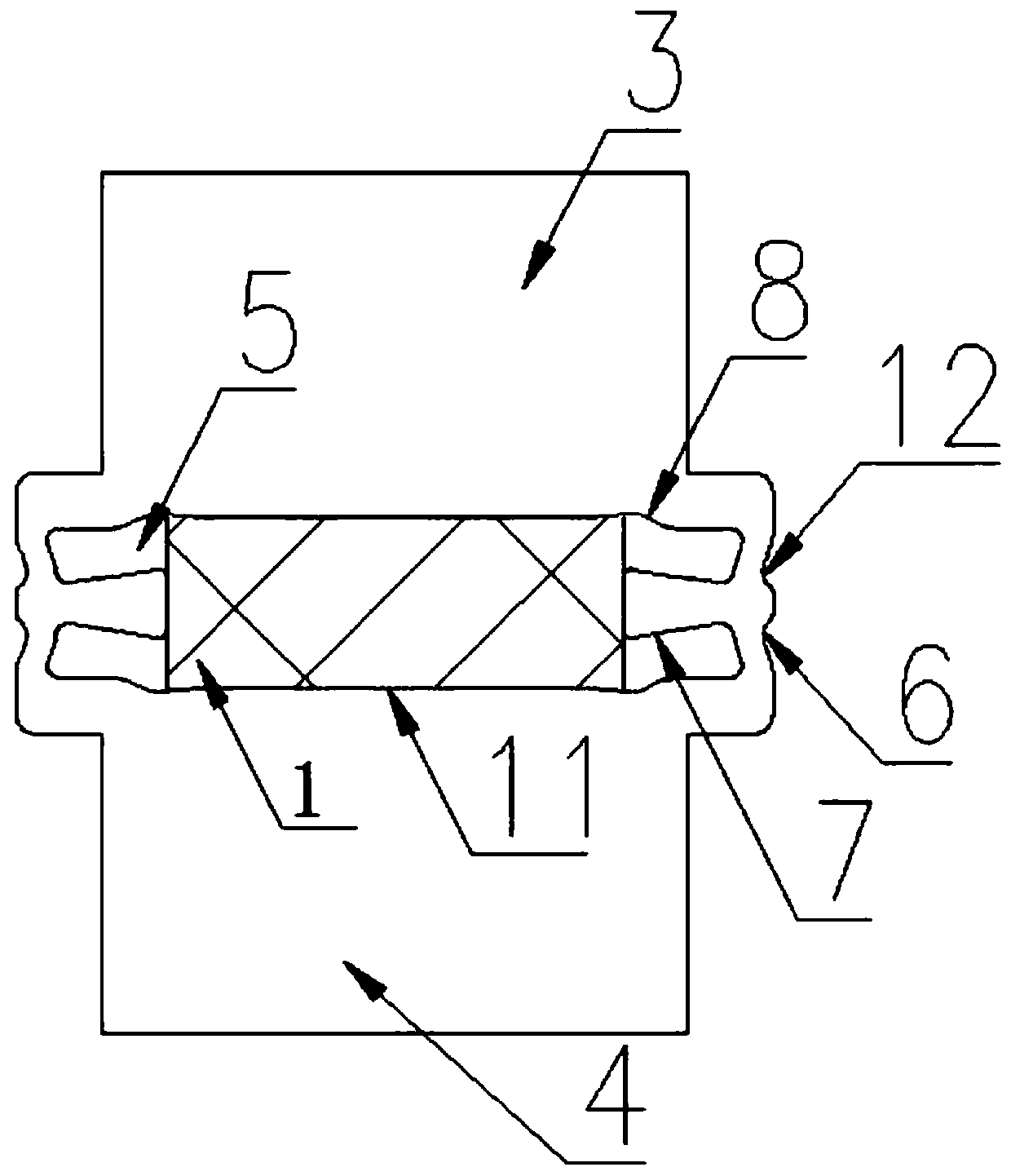

[0020] like figure 1 , figure 2 , Figure 4 As shown, the shovel-fin ceramic PTC electric heater includes a finned aluminum tube, a heating core 1 arranged on the finned aluminum tube, and the finned aluminum tube includes an aluminum tube 2 with a cavity 5, The first cooling fins 3 and the second cooling fins 4 are arranged on the upper and lower ends of the aluminum tube 2 respectively. The left and right sides of the heating core 1 are bonded to the left and right end surfaces of the heating core 1 after being molded laterally to form a left and right end surface heat dissipation structure.

[0021] The heat dissipation structure on the left and right end surfaces is a cooling fin provided on the left and right inner walls of the cavity 5 to facilitate the lamination of the heating core 1 and the left and right end surfaces of the aluminum tube 2 .

[0022] The heat sink is a trapezoidal heat sink 7 whose thickness gradually decreases from the heating core 1 to both sid...

Embodiment 2

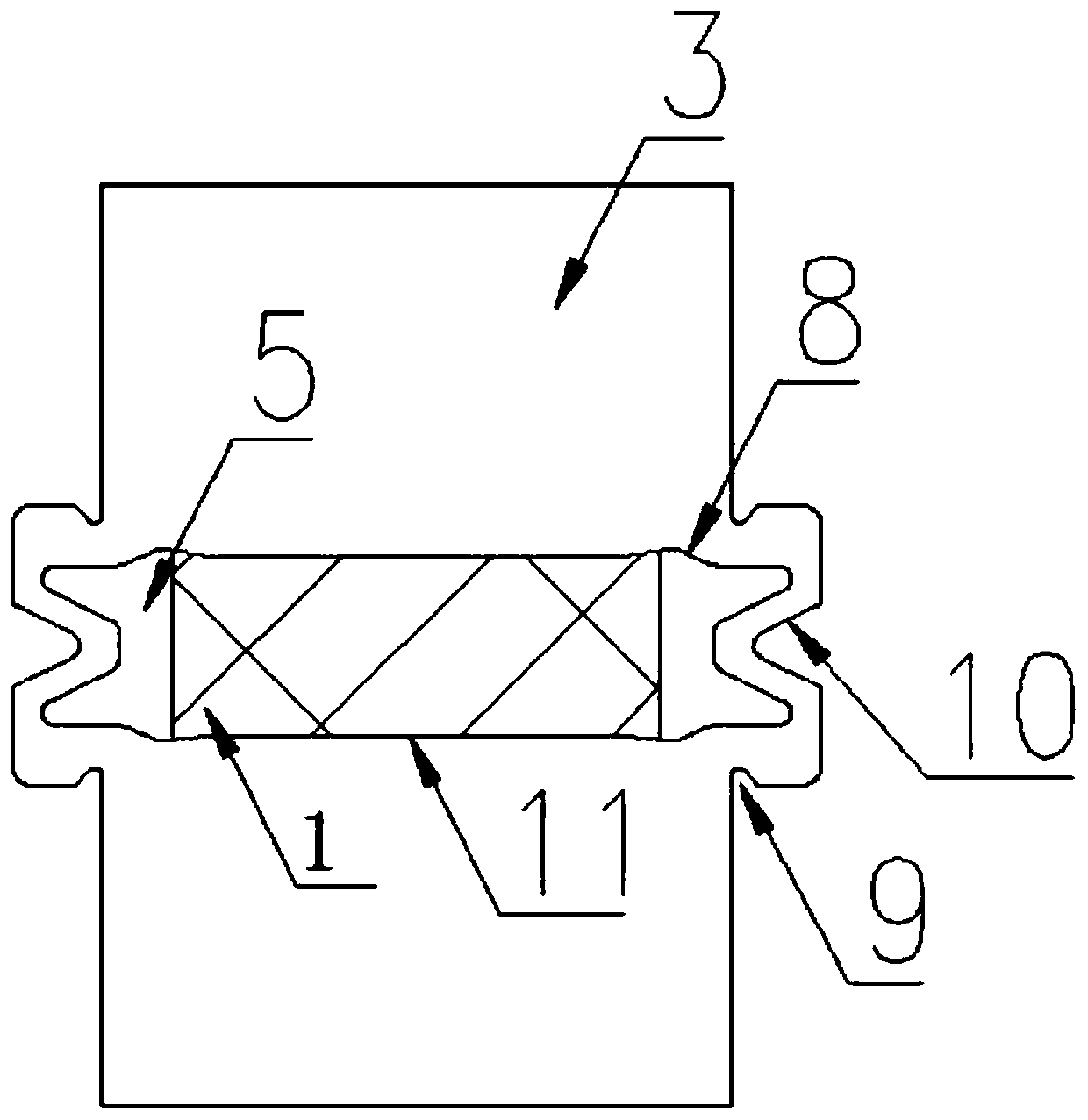

[0033] like figure 1 , image 3 , Figure 4 As shown, the shovel-fin ceramic PTC electric heater includes a finned aluminum tube, a heating core 1 arranged on the finned aluminum tube, and the finned aluminum tube includes an aluminum tube 2 with a cavity 5, The first cooling fins 3 and the second cooling fins 4 are arranged on the upper and lower ends of the aluminum tube 2 respectively. The left and right sides of the heating core 1 are bonded to the left and right end surfaces of the heating core 1 after being molded laterally to form a left and right end surface heat dissipation structure.

[0034] The heat dissipation structure on the left and right end surfaces is a V-shaped groove cooling fin 10 arranged on the side end surface of the aluminum tube 2 and having a V-shaped cross section.

[0035] Grooves 9 distributed along the length direction of the aluminum tube 2 are provided on the transition part between the first heat dissipation fin 3 and the second heat dissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com