Solder strip for IBC photovoltaic module

A technology of photovoltaic modules and welding strips, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problem of high temperature resistance of insulating paste, achieve precise thickness control, reduce stress concentration and easy cracking, and solve the problem of high temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

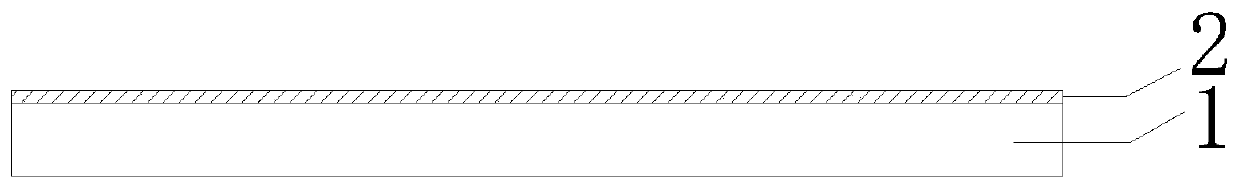

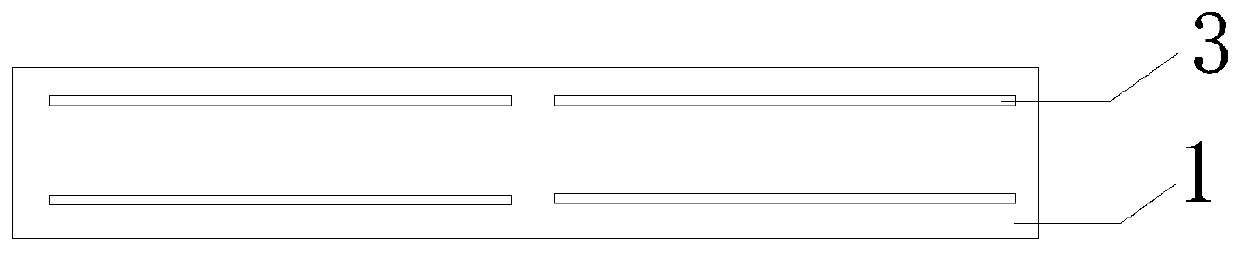

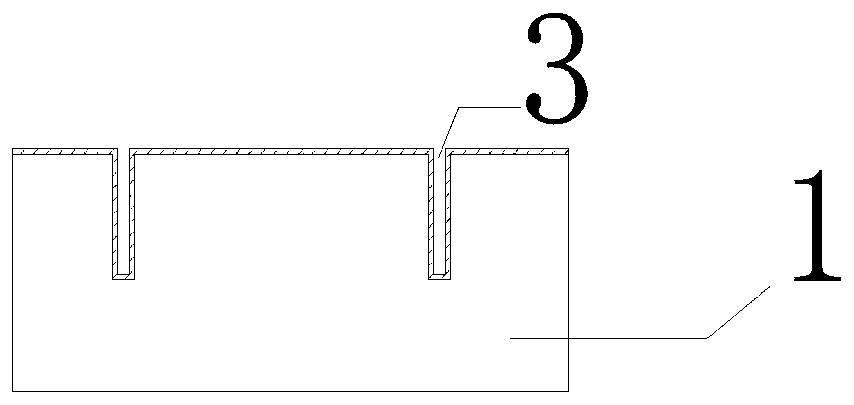

[0021] according to Figure 1 to Figure 3 As shown, the welding ribbon for IBC photovoltaic modules provided by the present invention includes a base material 1 and a coating 2 covering the surface of the base material 1. The base material 1 is provided with stress buffer grooves 3, and the stress buffer grooves 3 are distributed on the base material. In the length direction and the width direction of the material 1.

[0022] The substrate 1 is oxygen-free copper, the composition of the coating 2 is Sn 50-55wt%, Bi 10-15wt% and Pb35-40wt%, the melting point of the coating 2 is 160-180°C, and it can be welded at low temperature, and its stability, Fluidity, wettability are relatively good.

[0023] Preferably, when the composition of the coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com