Method for predicting service life of glass fiber reinforced plastic pipe

A prediction method and service life technology, applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of pipe life danger, chemical structure and performance changes, non-compliance, etc., and achieve high prediction reliability, short test period, and combined tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The service life of an acid anhydride-cured glass steel pipe with an outer diameter of D=85.3mm, a nominal pressure of PN=4Mpa, and a wall thickness of 3.1mm is predicted. The conditions for conveying fluids are shown in Table 1.

[0063] The condition parameter of table 1 embodiment 1 conveying fluid

[0064]

[0065] Specific steps are as follows:

[0066] Step 1: Hydrostatic pressure test, randomly select 18 glass steel pipes in the same batch, and make 18 samples with a pipe body length of 1500mm and a plugged joint at the end, each group is divided into 3 There are 6 groups, the group numbers are 1#, 2#, 3#, 4#, 5#, and 6#, and the hydrostatic pressure test is carried out for each group of pipes. The hydrostatic pressure test conditions are shown in Table 2.

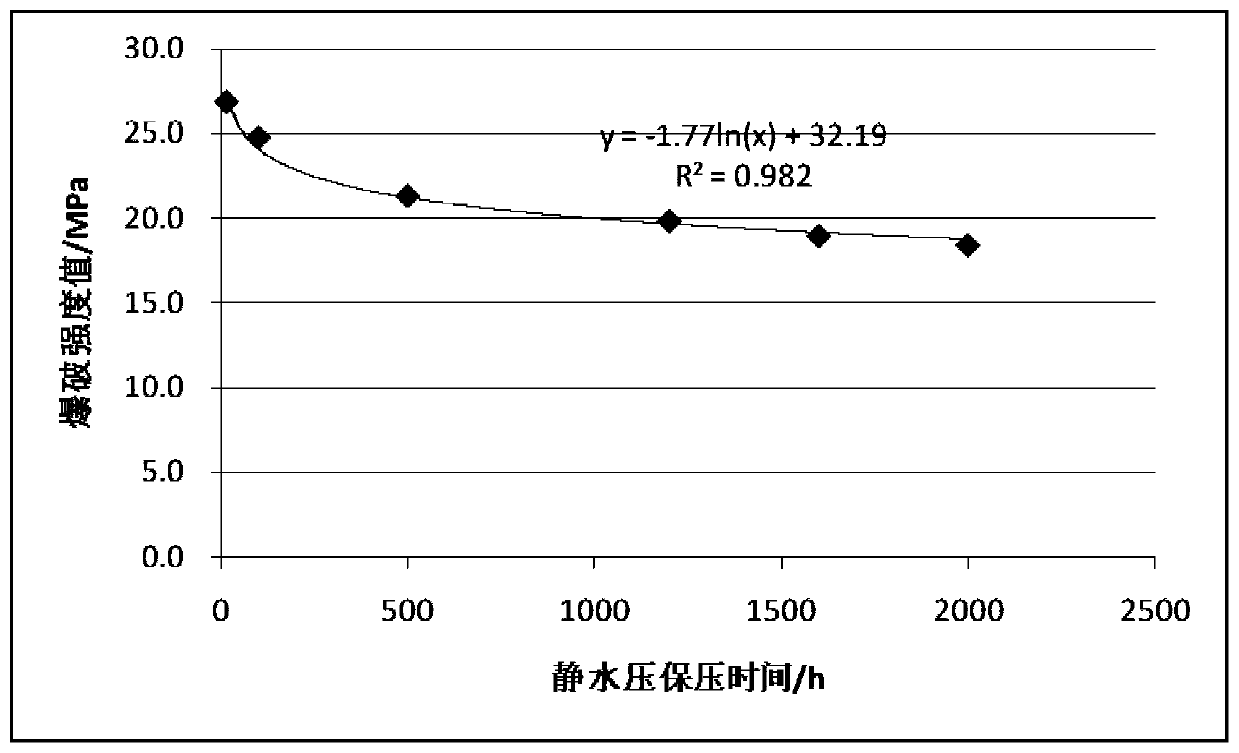

[0067] Table 2 The test condition and burst strength value of embodiment 1 hydrostatic pressure

[0068]

[0069]

[0070] Step 2: Hydrostatic blasting test, according to the standard GB5351 "Fiber...

Embodiment 2

[0084] The service life of an acid anhydride-cured glass steel pipe with an outer diameter of D = 85.3mm, a nominal pressure of PN = 4.0Mpa, and a wall thickness of 3.1mm is predicted. The conditions for conveying fluids are shown in Table 1.

[0085] Steps 1 to 8 are the same as in Example 1.

[0086] Step 9: Pipe life calculation, pipe safety critical pressure P s =f*PN, take f=2.0 here, then P s =f*PN=8.0Mpa, the P s =8.0Mpa into the equation P t =32.19-2.03ln(t), resulting in time t=17 years.

[0087] Therefore, if the safety critical pressure of the pipeline is set to 8.0MPa, the expected life of this batch of glass steel pipes is 17 years at 70°C and the environmental conditions mentioned in Table 1.

Embodiment 3

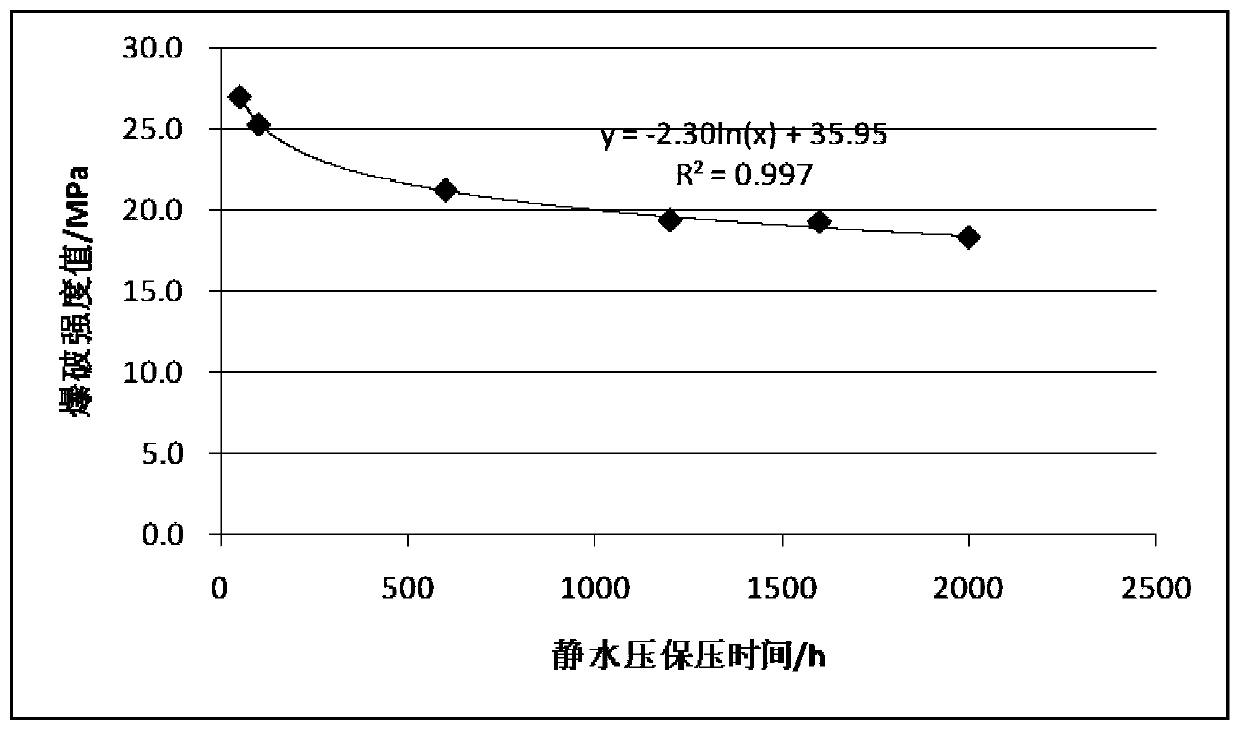

[0089]The service life of an acid anhydride-cured glass steel pipe with outer diameter D=110mm, nominal pressure PN=3Mpa, and wall thickness h=4mm is predicted. The conditions for conveying fluid are shown in Table 4.

[0090] Specific steps are as follows:

[0091] Step 1: Hydrostatic pressure test, randomly select 12 glass steel pipes in the same batch, and make 12 samples with a pipe body length of 1500mm and a plugged joint at the end, each group is divided into 2 There are 6 groups, the group numbers are 1#, 2#, 3#, 4#, 5#, and 6#, and the hydrostatic pressure test is carried out for each group of pipes. The hydrostatic pressure test conditions are shown in Table 5.

[0092] The condition parameter of table 4 embodiment 3 conveying fluid

[0093]

[0094] Table 5 embodiment 3 hydrostatic pressure test conditions and burst strength value

[0095]

[0096]

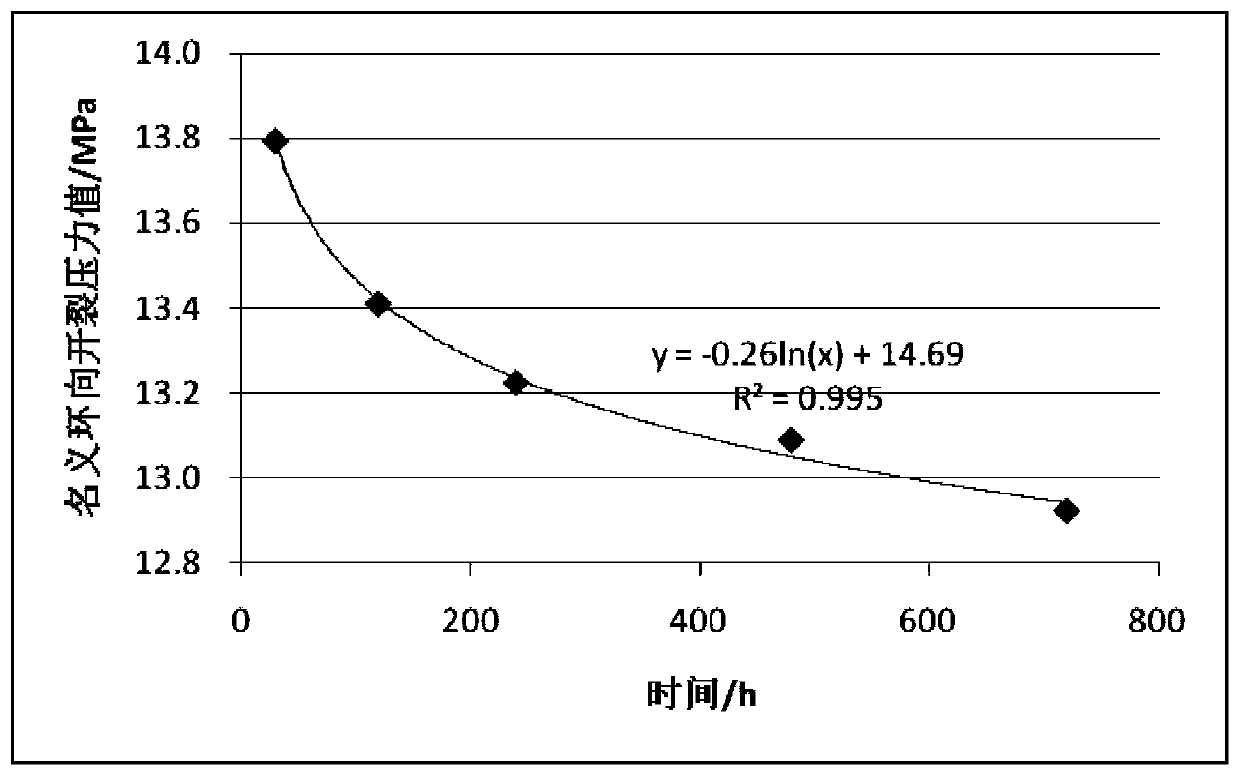

[0097] Step 2: Hydrostatic blasting test, according to the standard GB5351 "Fiber Reinforced Thermosetting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com