Tamping machine

A technology of tamping machine and rubber pad, which is applied in the direction of roads, road repairs, roads, etc. It can solve the problems that large tamping machines cannot work normally, cannot provide sufficient tamping, and increase energy consumption of the device. Achieve the effect of easy realization, convenient replacement and cleaning, and speed up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

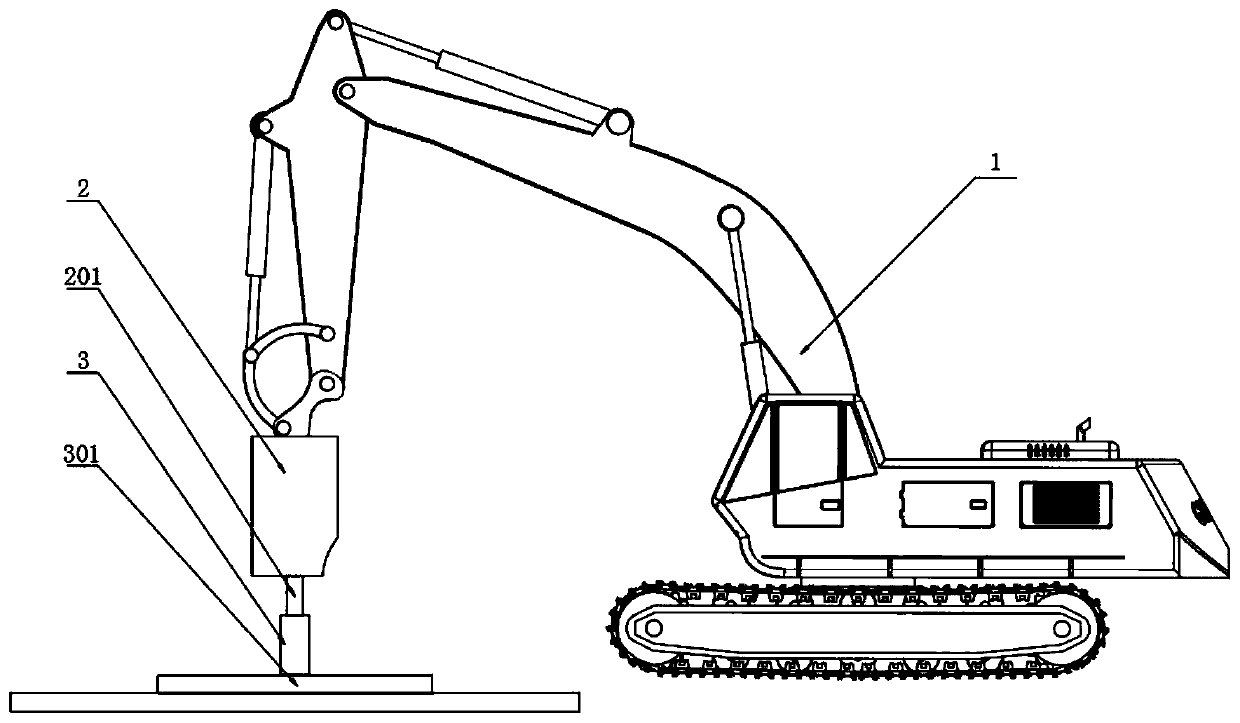

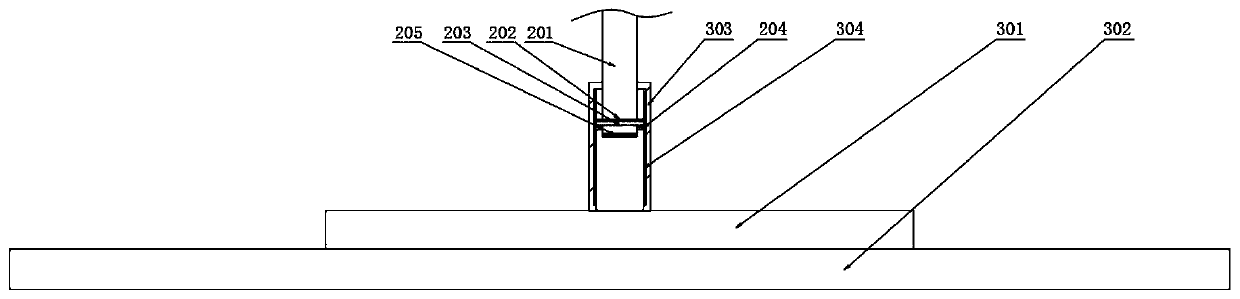

[0025] Such as Figure 1-3 As shown, a compacting machine includes an excavator 1 and a breaker 2. The output shaft 201 of the breaker 2 is slidably connected with a compacting mechanism 3, so that the output shaft 201 can continuously knock on the ground without driving the compacting mechanism 3. Hit the upper hammer plate 301 and enable the lower rammed earth plate 302 to continuously tamp the contacted ground, greatly reducing the output energy consumption of the breaking hammer 2, and speeding up the construction speed of the tamping operation;

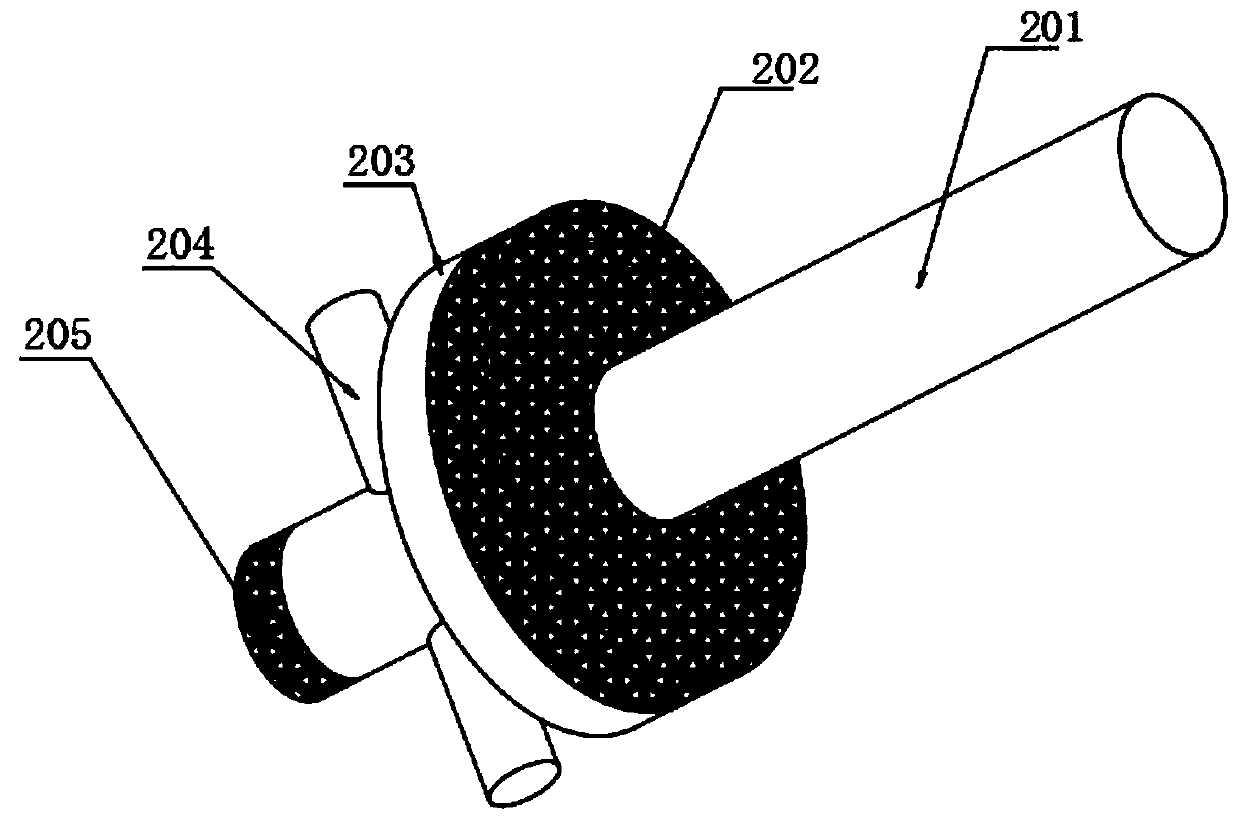

[0026] The output shaft 201 of the breaker 2 is provided with an anti-off plate 203, an upper rubber pad 202, several limit rods 204, and a lower rubber pad 205. Both the upper rubber pad 202 and the lower rubber pad 205 are used for buffering and vibration reduction. Effect, can prevent the deformation of the output shaft 201 and the tamping mechanism 3 caused by the impact, and can reduce the noise generated by the impact;

[...

Embodiment 2

[0030] Such as Figure 2-4 As shown, a compacting machine includes an excavator 1 and a breaker 2. The output shaft 201 of the breaker 2 is slidably connected with a compacting mechanism 3, so that the output shaft 201 can continuously knock on the ground without driving the compacting mechanism 3. Hit the upper hammer plate 301 and enable the lower rammed earth plate 302 to continuously tamp the contacted ground, greatly reducing the output energy consumption of the breaking hammer 2, and speeding up the construction speed of the tamping operation;

[0031] The output shaft 201 of the breaker 2 is provided with an anti-off plate 203, an upper rubber pad 202, several limit rods 204, and a lower rubber pad 205. Both the upper rubber pad 202 and the lower rubber pad 205 are used for buffering and vibration reduction. Effect, can prevent the deformation of the output shaft 201 and the tamping mechanism 3 caused by the impact, and can reduce the noise generated by the impact;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com