Ship sewage treatment device and method

A sewage treatment device and ship technology, applied in the field of water treatment, can solve the problems of incomplete water treatment, low fresh water recycling rate, etc., and achieve the effect of reducing output energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

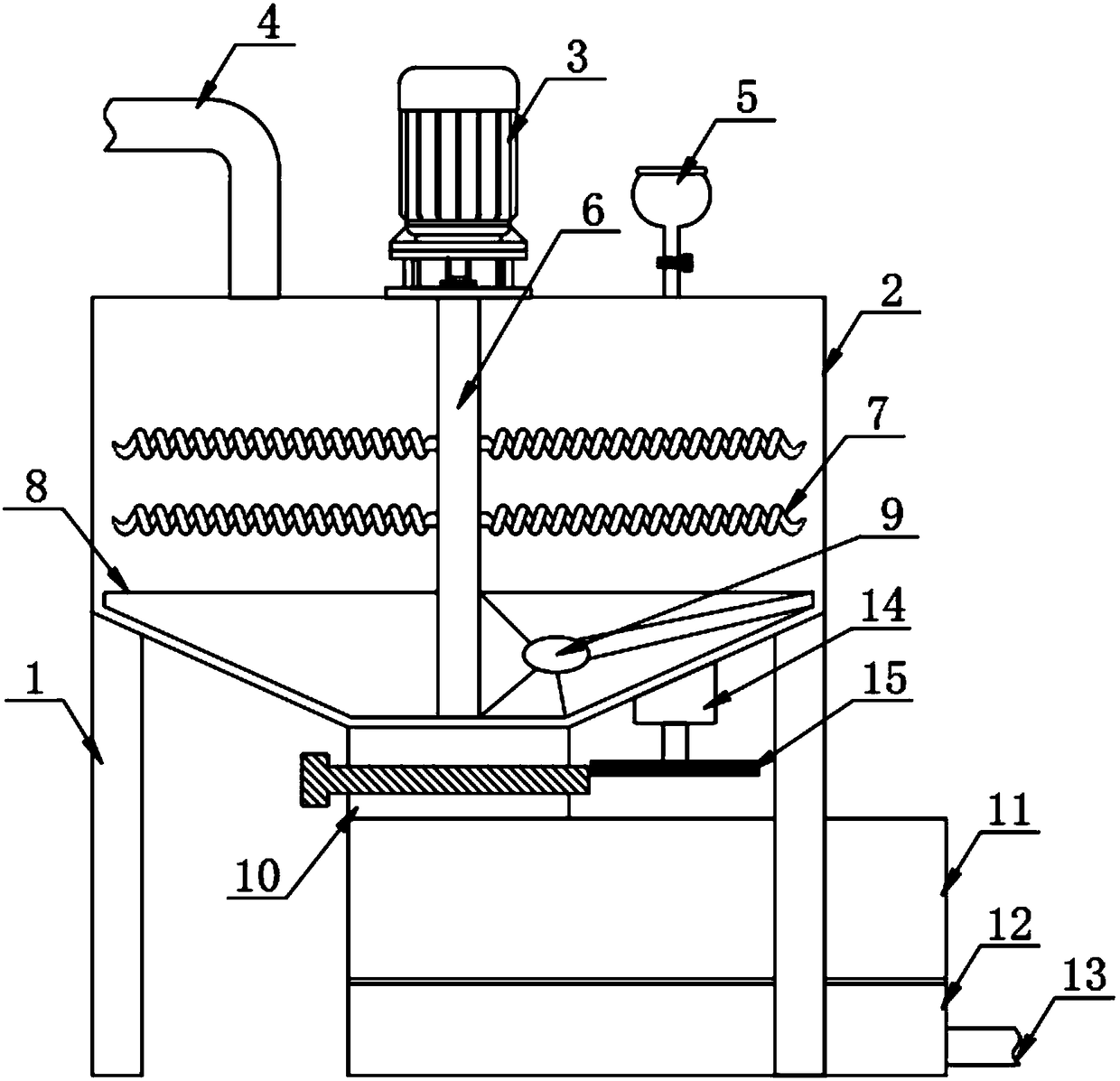

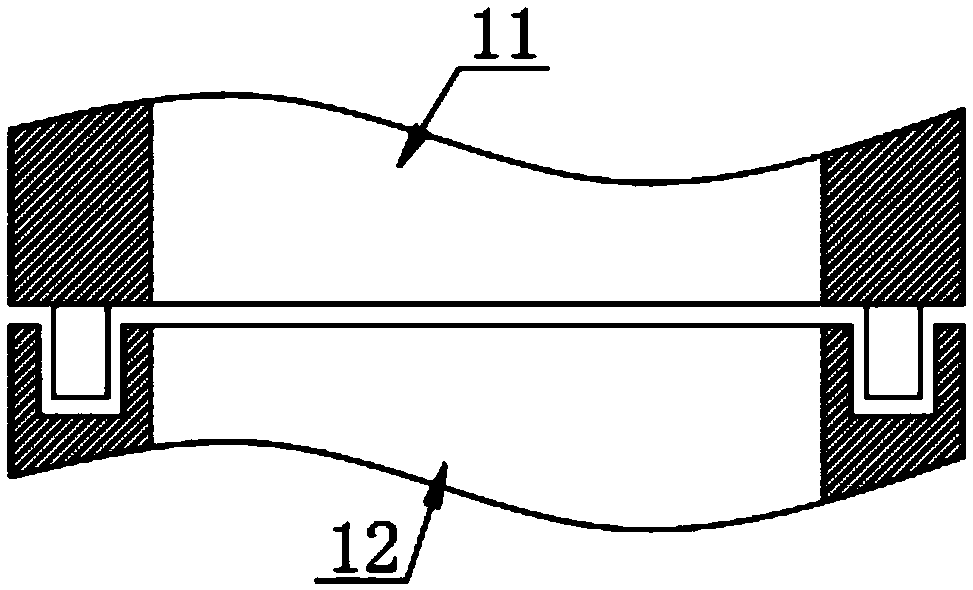

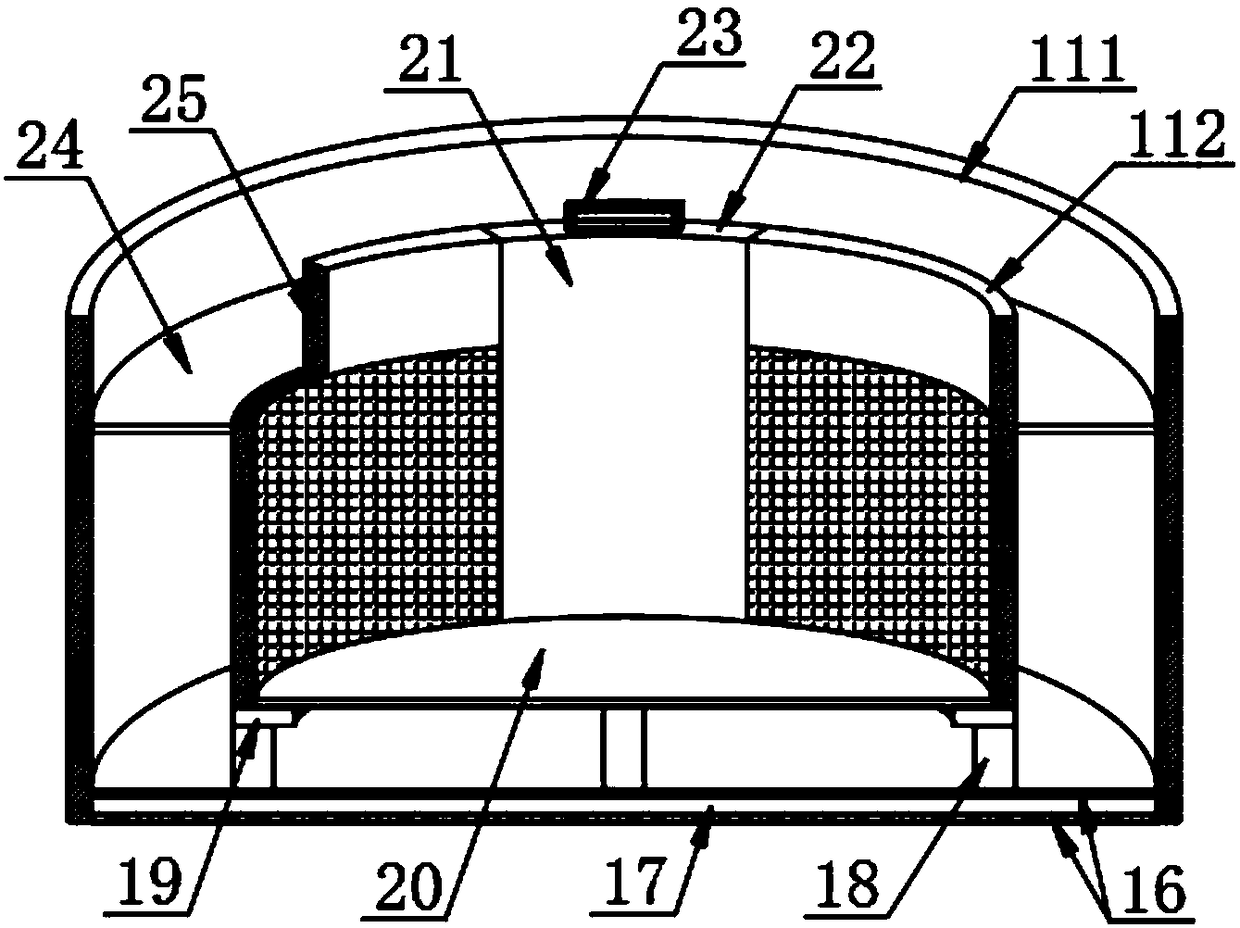

[0030] The present invention provides such Figure 1-4 The shown ship sewage treatment device includes a frame 1, a pretreatment cylinder 2 is fixed on the top of the frame 1, a motor 3 is arranged at the center of the top of the pretreatment cylinder 2, and a motor 3 is arranged on one side There is a water inlet pipe 4 and the other side is provided with a dosing hopper 5, the water inlet pipe 4 and the dosing hopper 5 are all connected with the pretreatment cylinder 2, and the end of the output shaft of the motor 2 is fixedly connected with a rotating shaft 6, so The middle part of the circumferential side of the rotating shaft 6 is fixed with a stirring rod 7 and a scraper 8 at the bottom, and a connecting pipe 10 is arranged at the center of the bottom of the pretreatment cylinder 2, and the connecting pipe 10 and the dosing bucket 5 are all provided with There is a control valve, and a hydraulic cylinder 14 is arranged on one side of the connecting pipe 10, and the hydra...

Embodiment 2

[0039] A ship sewage treatment method, including the ship sewage treatment device, also includes the following steps:

[0040] S1: connect the sewage treatment device with an external power supply;

[0041] S2: Then pass the sewage into the pretreatment cylinder 2 from the water inlet pipe 4;

[0042] S3: Open the control valve on the dosing hopper 5, so that the medicine in the dosing hopper 5 enters the pretreatment cylinder 2, and at the same time, start the motor 3 to work through the external controller to drive the rotating shaft to rotate, thereby using the stirring rod 7 and The scraper 8 stirs the sewage in the pretreatment cylinder 2;

[0043] S4: The curved surface 9 has a tapered structure design from the outside of the scraper 8 to the center, and its end surface is set as a spherical surface to scrape off the remaining flocs on the inner wall of the pretreatment cylinder 2;

[0044] S5: Open the control valve on the connecting pipe 10, so that the sewage mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com