A kind of high anti-sulfur silver plating solution and using method thereof and high anti-sulfur silver plating layer

A high-sulfur-resistant and silver-plated technology, applied in the field of high-sulfur-resistant silver-plated layer and high-sulfur-resistant silver-plated solution, can solve the problem that the sulfur-resistant performance is difficult to meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] surface treatment

[0050] Grinding: first use 800-mesh sandpaper for rough grinding, and then use 1000-mesh sandpaper for fine grinding.

[0051] Strong alkali chemical degreasing: Table 1-1 shows the strong alkali degreasing process.

[0052] Table 1-1 strong alkali degreasing process table

[0053] Element content unit NaOH 60 g / L Operating temperature 20 ℃ time 1 h

[0054] Pickling: The copper substrate after strong alkali chemical degreasing is first rinsed with distilled water, then soaked in the pickling solution, and then taken out. Table 1-2 is the pickling process table.

[0055] Table 1-2 is the pickling process table

[0056] Element content unit HNO 3

300 g / L Operating temperature 20 ℃ time 20 s

[0057] pre-silvered

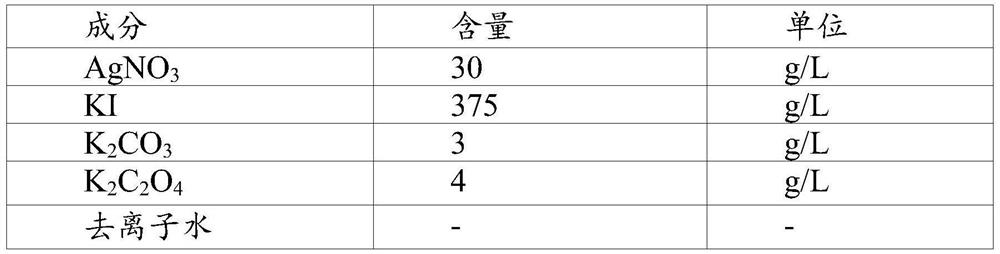

[0058] Put the treated copper substrate into the silver plating liquid for pre-silver plating. Table 1-3 is the pre-silvering process table.

[0059] T...

Embodiment 2

[0071] surface treatment

[0072] Grinding: first use 800-mesh sandpaper for rough grinding, and then use 1000-mesh sandpaper for fine grinding.

[0073] Strong alkali chemical degreasing: Table 2-1 shows the strong alkali degreasing process.

[0074] Table 2-1 strong alkali degreasing process table

[0075] Element content unit NaOH 60 g / L Operating temperature 20 ℃ time 1.5 h

[0076] Pickling: The copper substrate after strong alkali chemical degreasing is first rinsed with distilled water, then soaked in the pickling solution, and then taken out. Table 2-2 is the pickling process table.

[0077] Table 2-2 is the pickling process table

[0078] Element content unit HNO 3

300 g / L Operating temperature 20 ℃ time 30 s

[0079] pre-silvered

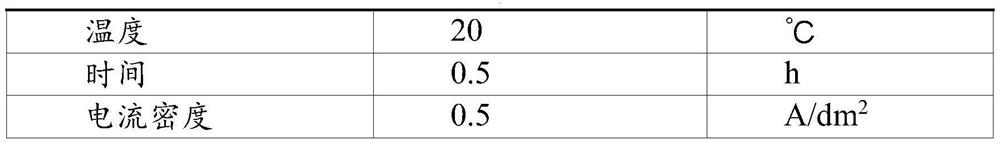

[0080] Put the treated copper substrate into the silver plating liquid for pre-silver plating. Table 2-3 is the pre-silvering process table.

[0081]...

Embodiment 3

[0093] surface treatment

[0094] Grinding: first use 800-mesh sandpaper for rough grinding, and then use 1000-mesh sandpaper for fine grinding.

[0095] Strong alkali chemical degreasing: Table 3-1 shows the strong alkali degreasing process.

[0096] Table 3-1 strong alkali degreasing process table

[0097] Element content unit NaOH 60 g / L Operating temperature 20 ℃ time 1.2 h

[0098] Pickling: The copper substrate after strong alkali chemical degreasing is first rinsed with distilled water, then soaked in the pickling solution, and then taken out. Table 3-2 is the pickling process table.

[0099] Table 3-2 is the pickling process table

[0100] Element content unit HNO 3

300 g / L Operating temperature 20 ℃ time 35 s

[0101] pre-silvered

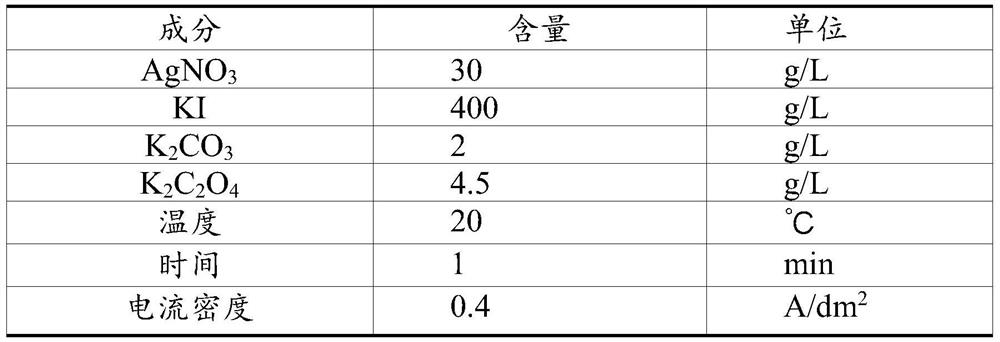

[0102] Put the treated copper substrate into the silver plating liquid for pre-silver plating. Table 3-3 is the pre-silvering process table.

[0103]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com