Underwear type laundry condensate beads and preparation method thereof

A technology for washing beads and personal clothing, which is applied in the field of daily chemical detergents. It can solve the problems of antibacterial and mite removal, achieve excellent decontamination ability, excellent foam control performance, and ensure decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

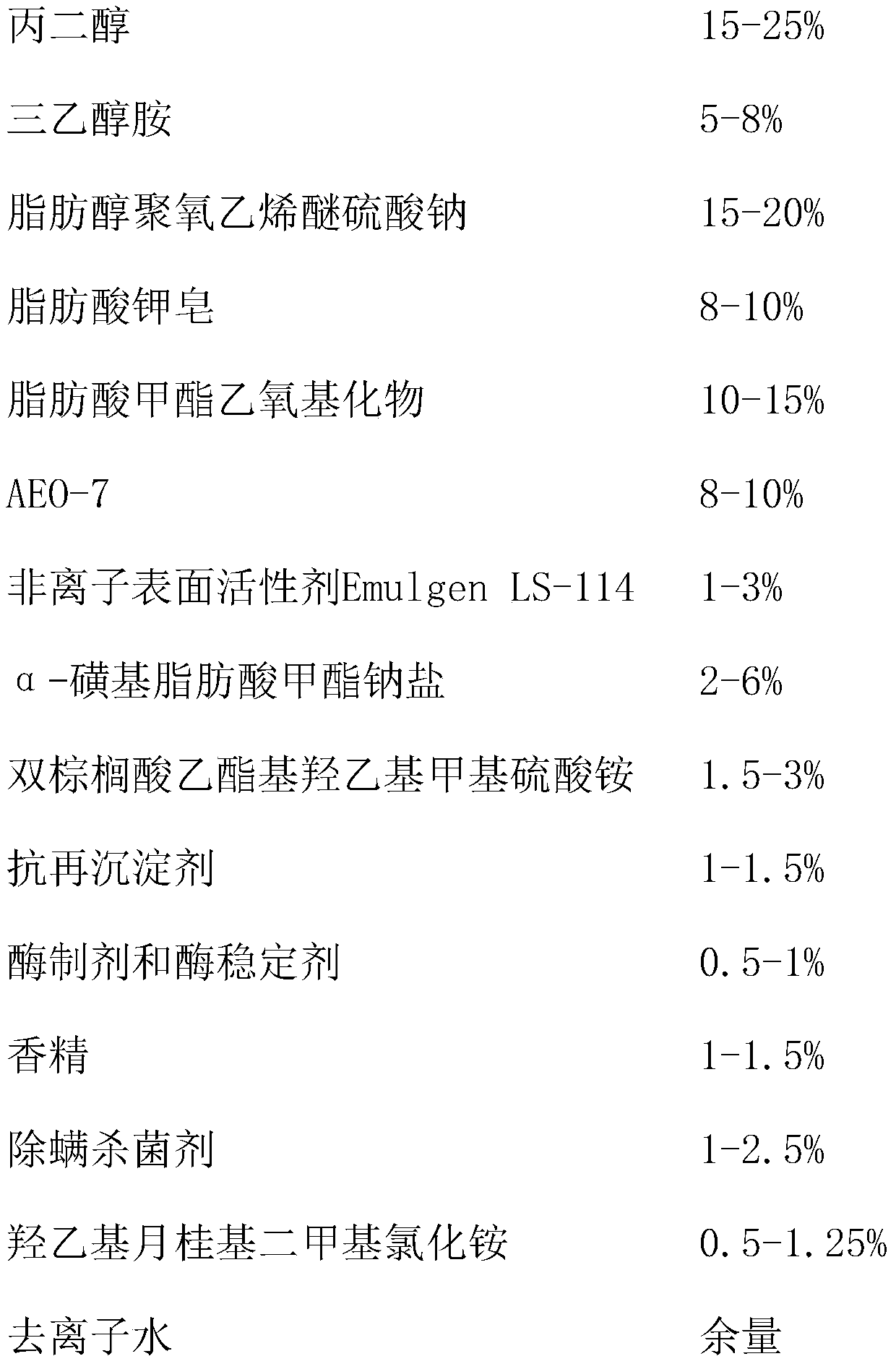

[0035] A kind of personal clothing type laundry beads, comprising the following components by mass percentage:

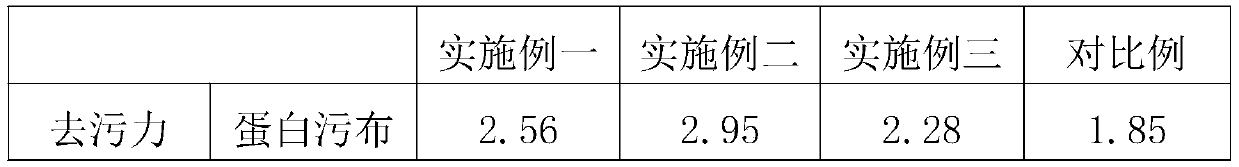

[0036] 15% propylene glycol, 5% triethanolamine, 20% sodium fatty alcohol polyoxyethylene ether sulfate, 8% fatty acid potassium soap, 15% fatty acid methyl ester ethoxylate, 10% AEO-7, 3% nonionic surfactant EmulgenLS -114, 2% α-sulfo fatty acid methyl ester sodium salt, 3% dipalmitoethyl hydroxyethyl ammonium methyl sulfate, 1% acrylic acid / styrene copolymer (molecular weight 30000), 0.02% protease, 0.025% Lipase, 0.19% sodium citrate, 0.113% mannitol, 0.152% chitosan, 1% microcapsule flavor, 0.8% p-hydroxyacetophenone, 0.4% ethylhexylglycerin, 0.8% camphor oil, 0.5% non-toxic Subsaponin, 0.5% hydroxyethyl lauryl dimethyl ammonium chloride, and the balance is deionized water.

[0037] A kind of preparation method of intimate clothing class laundry pod, comprises the following steps:

[0038] (1) Weigh each raw material according to the preset mass percentage;

[...

Embodiment 2

[0043] A kind of personal clothing type laundry beads, comprising the following components by mass percentage:

[0044] 20% propylene glycol, 8% triethanolamine, 15% sodium fatty alcohol polyoxyethylene ether sulfate, 10% fatty acid potassium soap, 10% fatty acid methyl ester ethoxylate, 9% AEO-7, 2% nonionic surfactant EmulgenLS -114, 6% α-sulfo fatty acid methyl ester sodium salt, 1.5% dipalmitoethyl hydroxyethyl ammonium methyl sulfate, 1.5% acrylic acid / styrene copolymer (molecular weight 30000), 0.06% protease, 0.03% Amylase, 0.46% sodium citrate, 0.11% mannitol, 0.34% chitosan, 1.5% microcapsule flavor, 0.2% p-hydroxyacetophenone, 0.1% ethylhexylglycerin, 0.4% camphor oil, 0.3% non-toxic Subsaponin, 1.2% hydroxyethyl lauryl dimethyl ammonium chloride, and the balance is deionized water.

[0045] A kind of preparation method of intimate clothing class laundry pod, comprises the following steps:

[0046] (1) Weigh each raw material according to the preset mass percentage...

Embodiment 3

[0051] A kind of personal clothing type laundry beads, comprising the following components by mass percentage:

[0052] 25% propylene glycol, 6% triethanolamine, 17% sodium fatty alcohol polyoxyethylene ether sulfate, 9% fatty acid potassium soap, 12% fatty acid methyl ester ethoxylate, 8% AEO-7, 1% nonionic surfactant EmulgenLS -114, 4% α-sulfo fatty acid methyl ester sodium salt, 2% dipalmitoethyl hydroxyethyl ammonium methyl sulfate, 1.2% acrylic acid / styrene copolymer (molecular weight 30000), 0.04% lipase, 0.024 % cellulase, 0.35% sodium citrate, 0.04% mannitol, 0.246% chitosan, 1.2% microcapsule essence, 0.4% p-hydroxyacetophenone, 0.2% ethylhexylglycerin, 0.7% camphor oil, 0.3% Soapberry saponin, 0.8% hydroxyethyl lauryl dimethyl ammonium chloride, and the balance is deionized water.

[0053] A kind of preparation method of intimate clothing class laundry pod, comprises the following steps:

[0054] (1) Weigh each raw material according to the preset mass percentage; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com