An automatic coating device for compound fertilizer production

A coating device and compound fertilizer technology, applied in the direction of fertilization device, application, fertilizer mixture, etc., can solve the problems of low coating efficiency, poor coating effect, and complexity, and achieve high coating efficiency, good contact, and uniform coating film effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

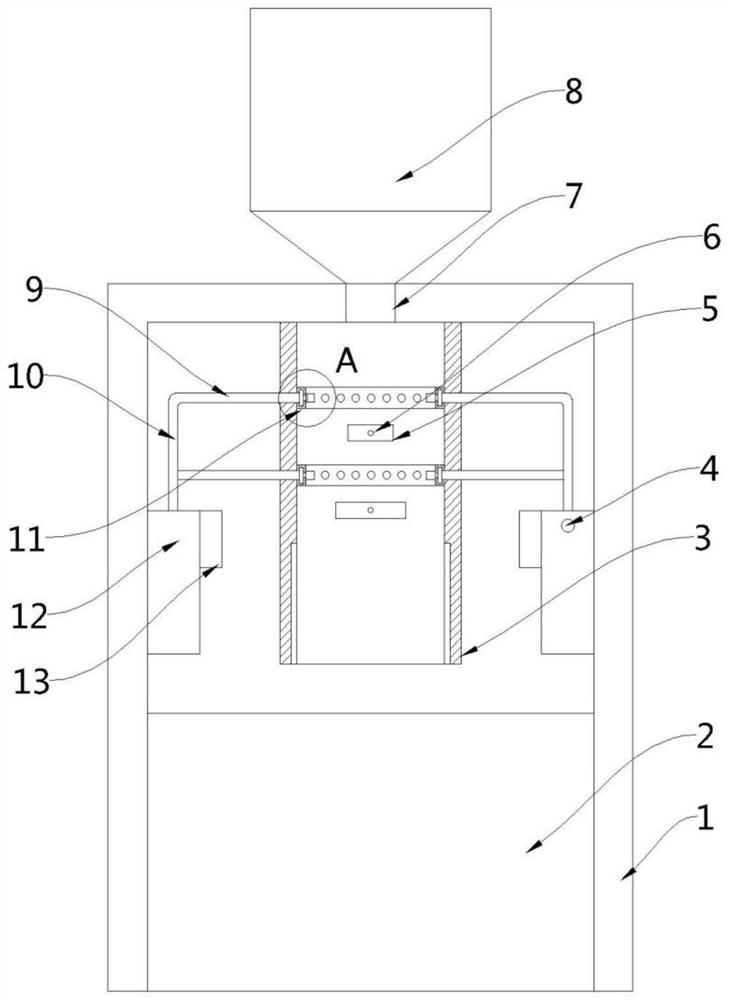

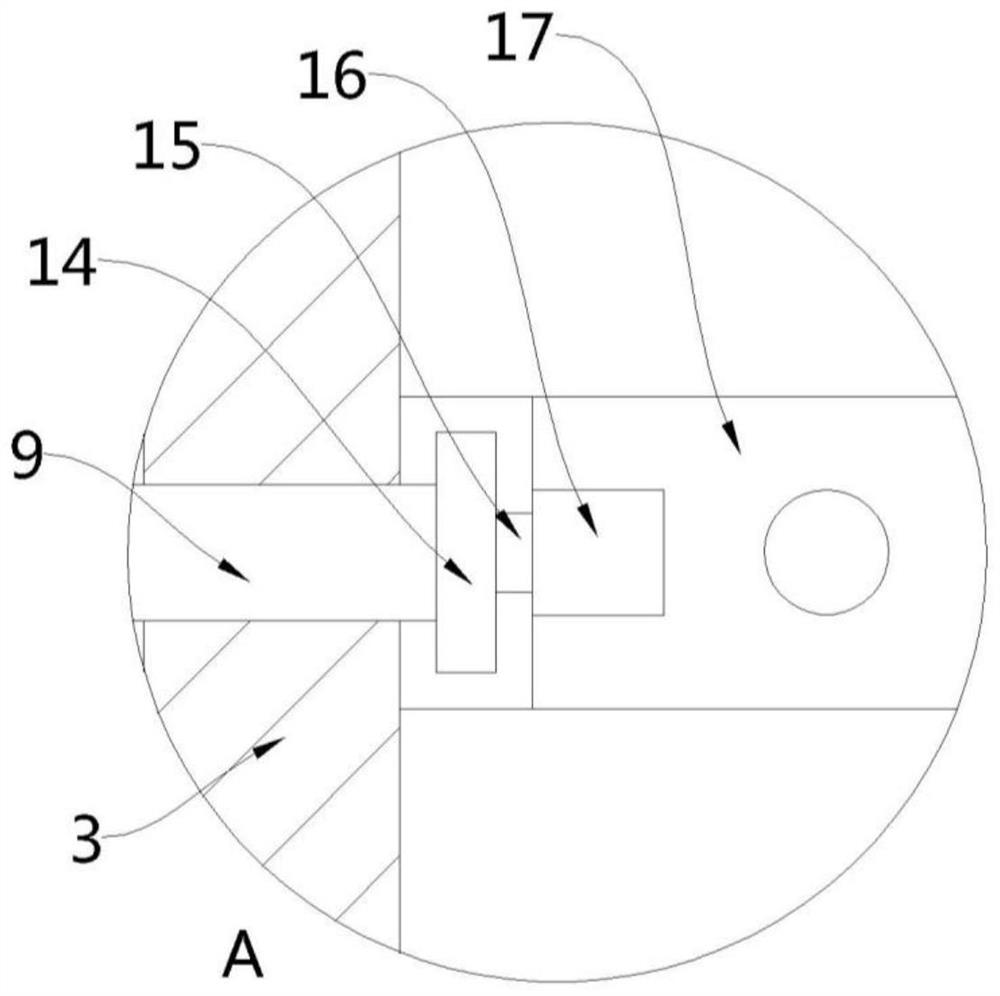

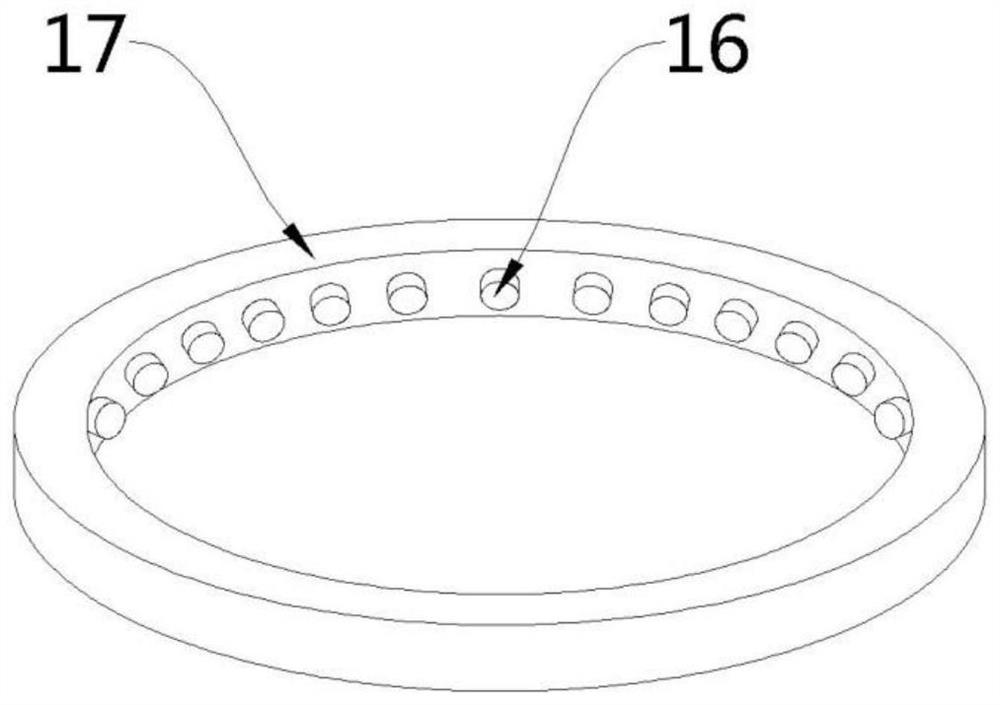

[0023] see Figure 1-3 , this embodiment provides an automatic coating device for compound fertilizer production, including a support 1, a storage tank 8 is arranged on the upper part of the support 1, and the bottom of the storage tank 8 extends to the support through a feeding nozzle 7 1 inside, the top of the support 1 is fixed with a feeding channel 3, and the inner wall of the feeding channel 3 is provided with a number of film-coated components 11 distributed vertically, and each set of film-covered components 11 is provided with a shaker Assembly, specifically, the coating assembly 11 includes a coating ring plate 17 axially distributed along the inner wall of the discharge channel 3 and a number of atomizing nozzles 16 installed on the inner side of the coating ring plate 17 and evenly distributed in a ring , the inside of the film-coated ring plate 17 is provided with an oil inlet passage 14, the inner side wall of the support 1 is provided with an oil storage tank 12...

Embodiment 2

[0033] see figure 1 , an automatic coating device for compound fertilizer production. Compared with Embodiment 1, the present embodiment is provided with a material receiving box 2 below the feeding channel 3. Through the setting of the material receiving box 2, the coating can be completed. The final compound fertilizer raw materials are stored.

[0034] The embodiment of the present invention has the advantages of good coating effect and high coating efficiency. The coating oil inside the oil storage tank 12 is pressed into the oil inlet channel 14 from the oil inlet main pipe 10 and the oil inlet branch pipe 9 through the booster pump 13, and then Enter the atomizing nozzle 16 from the oil inlet hole 15, spray out after atomizing through the atomizing nozzle 16, so that the coating oil is coated on the compound fertilizer raw material falling through the feeding channel 3, and the coating operation is realized; The setting of the material component can shake the falling co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com