Low-floor pure electric bus

A pure electric bus, low-floor technology, applied in the direction of electric power units, power units, vehicle components, etc., can solve the problems of large number of power battery packs, unfavorable maintenance and repair, and large space occupation, so as to achieve efficient operation and realize vehicle Full interior low floor design, convenient inspection and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

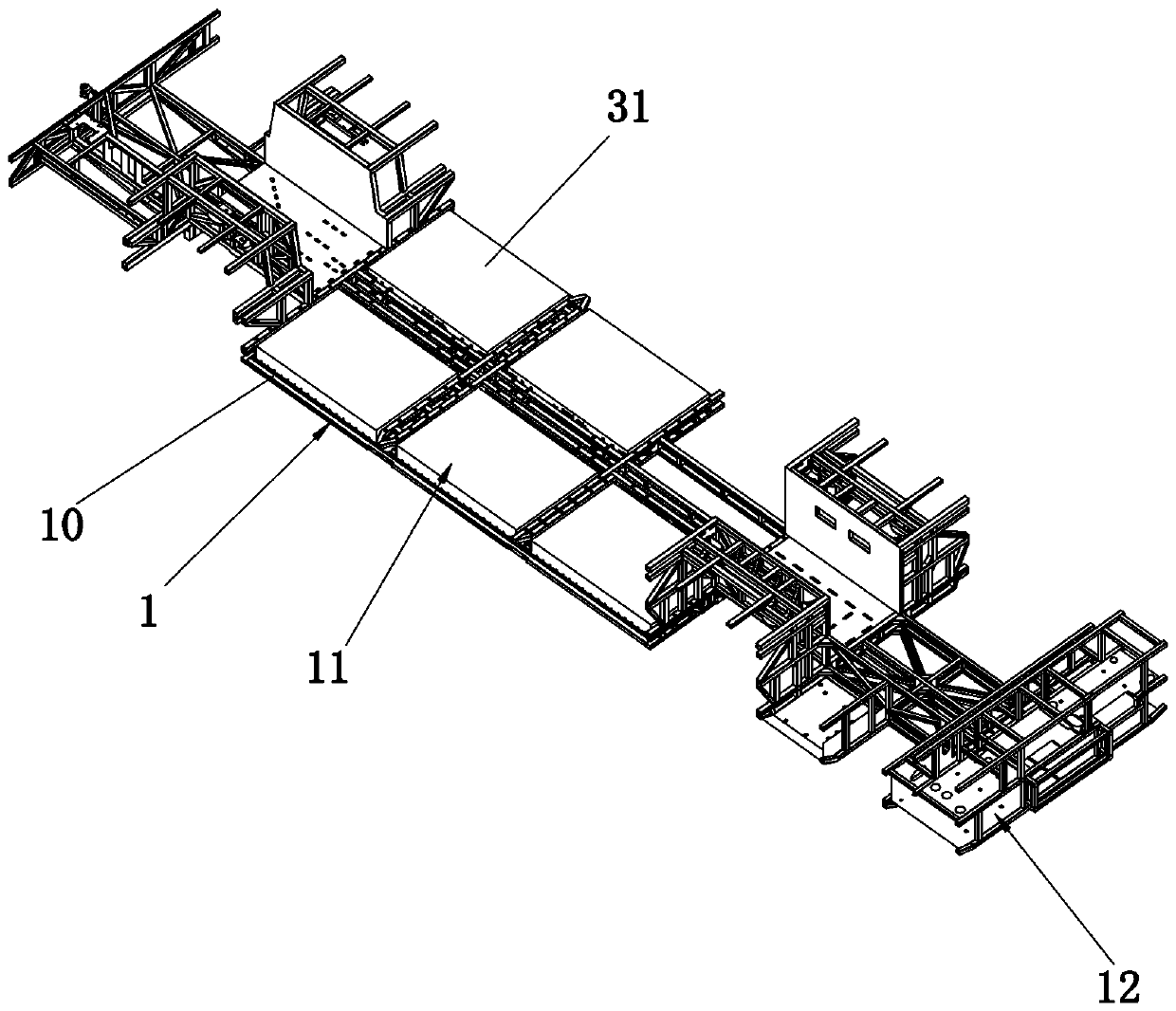

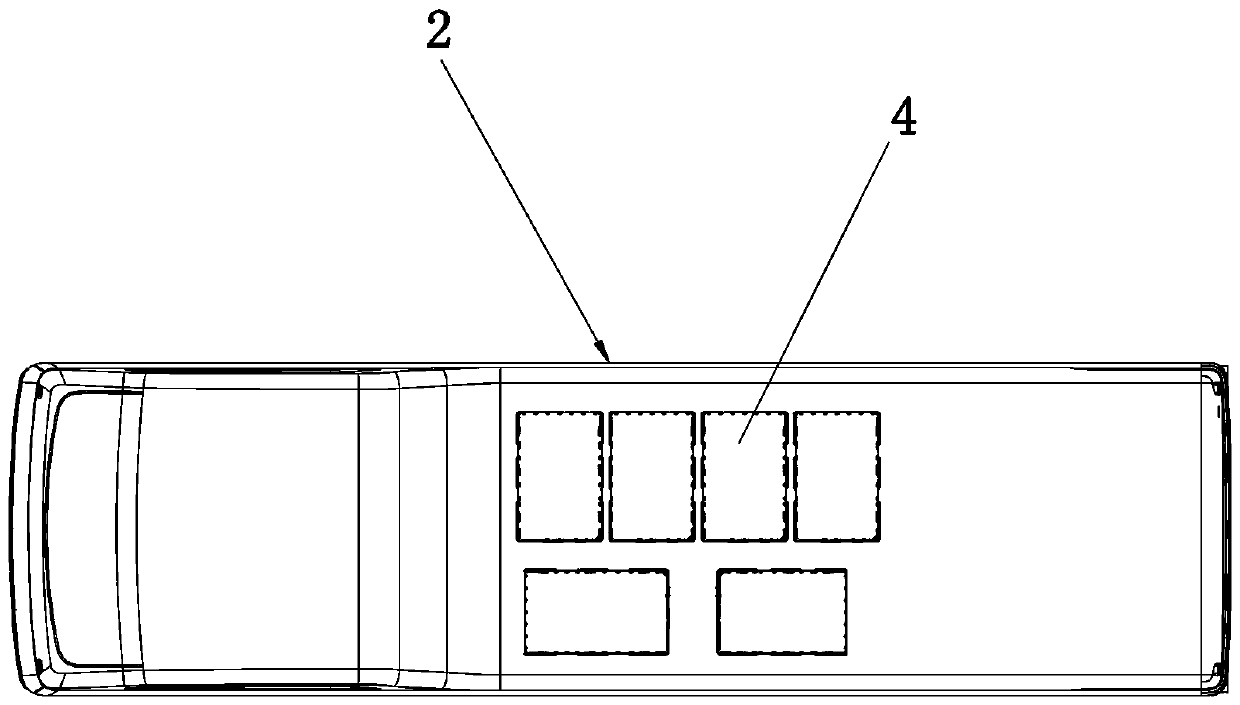

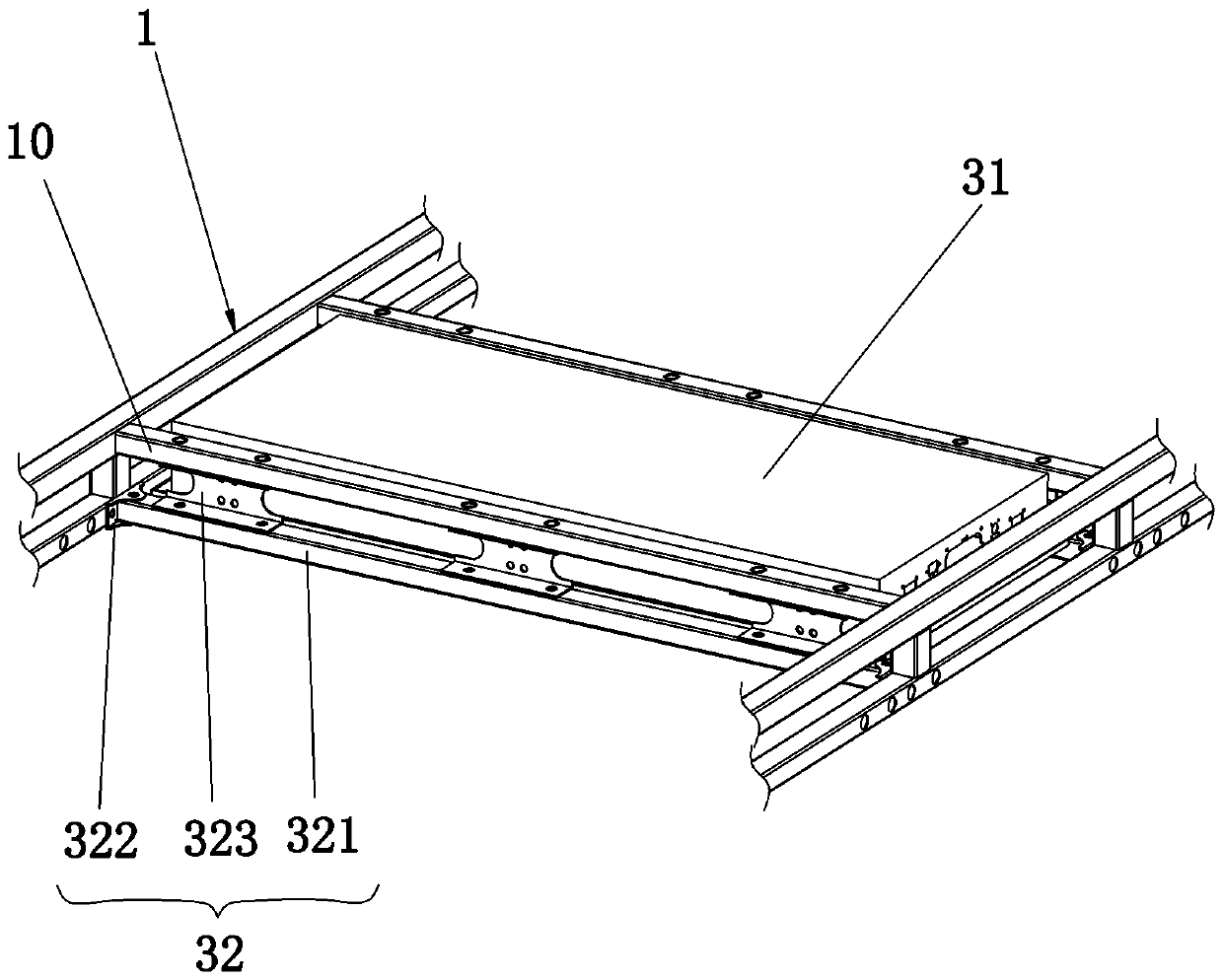

[0030] refer to Figure 1 to Figure 3 , a low-floor pure electric passenger car, including a chassis 1, a top cover 2 and a plurality of first battery packs, the chassis 1 is spliced into a truss structure by a plurality of steel pipes 10, and the middle section of the chassis 1 is provided with a plurality of installation cabins 11; each Each of the first battery packs includes a plurality of short battery cells connected in series and parallel, and the first battery packs are detachably installed in the installation compartment 11 . The present invention makes a breakthrough by adopting short battery cells to fully compress the height of the battery compartment 11, thereby effectively controlling the height of the bottom frame 1 from the ground, ensuring that one step can be achieved, and making the bottom frame 1 flat without steps, realizing The front-to-rear horizontal full low floor design in the car improves the safety and handling stability of the vehicle, making the...

Embodiment 2

[0038] refer to Figure 1 to Figure 5, different from Embodiment 1, the connection assembly 32 in this embodiment includes cross beams 324 and longitudinal beams 325 overlapping each other; the cross beams 324 are arranged on both sides of the bottom of the battery box 31, and the two ends of several longitudinal beams 325 pass through L The shape connecting frame 326 is connected to the bottom frame 1. During installation, cross beam 324 and longitudinal beam 325 can be overlapped first, then battery box is installed on cross beam 324, and finally the two ends of longitudinal beam 325 are arranged on the steel pipe 10 of underframe 1 through L-shaped connecting frame 326 and get final product. The beam 324 and the longitudinal beam 325 not only serve to fix the power battery, but also can effectively strengthen the structural strength of the middle section of the chassis 1 .

Embodiment 3

[0040] refer to Figure 1 to Figure 6 , different from Embodiment 1 and Embodiment 2, the connection assembly 32 in this embodiment includes several mounting brackets 327, one end of the mounting bracket 327 is provided with a mounting surface for fixing the battery box 31, and the other end is provided with a mounting surface for Connect the connection part of the base frame 1. The installation bracket 327 has a simple structure and an ingenious design, which is beneficial to realize quick installation and disassembly of the battery box 31 and the bottom frame 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com