Elastic cathode ring for electroosmosis dehydrator

A technology of electroosmotic dehydrator and cathode ring, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems such as the tightness of the drum and the filter screen, and achieve the advantages of difficult sliding, improved dehydration effect, and improved equipment reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

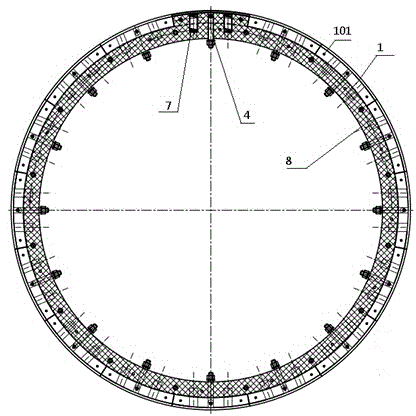

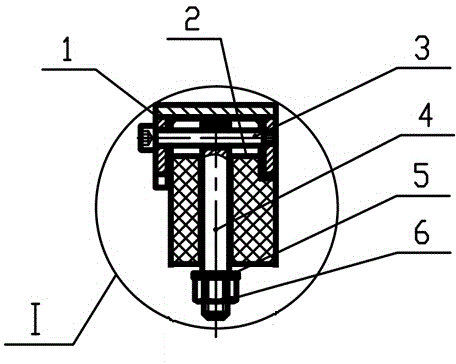

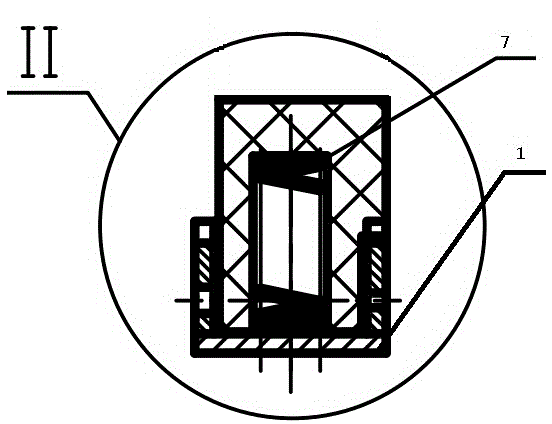

[0038] This embodiment provides an elastic cathode ring, which is used in electroosmotic dewatering sludge treatment equipment to supply power to the cathode filter in the electric field. The elastic cathode ring includes:

[0039] 1. Conductive plate, 2. Base, 3. Hinge screw, 4. Hinge pull rod, 5. Flat pad, 6. Lock nut, 7. Return spring. The base is fixed on the end plate of the roller and is concentric with the roller. The conductive plate is evenly distributed on the outer circumference of the cathode base in a ring shape, connected with the base 2 through the hinge screw 3 and the hinge pull rod 4, and can move up and down to a certain extent. Return spring 7 rebounds after being compressed, is limited by flat pad 5 and lock nut 6, adjusts the number of flat pads 5, and controls the height of the outer circumference of the cathode ring.

[0040] To sum up, through the elastic cathode ring in the embodiment of the present invention, the elastic cathode ring has a flexible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com