Grading method of machine-made sand for dry-mixed mortar and prepared dry-mixed mortar

A technology for dry-mixed mortar and machine-made sand, applied in the field of construction mortar, can solve the problems of unstable quality, gradation, powder content in sand, soil powder content and moisture that cannot be controlled within the standard range, and achieves good workability. , The effect of improving bond strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, the gradation design of machine-made sand

[0034] In the present invention, the medium sand in the machine-made sand, that is, the part below 4.75mm and the fineness modulus between 2.3-3.0, is screened again into three kinds of coarse, medium and fine sands, wherein the fineness modulus of the coarse sand is 4.3-4.6, The fineness modulus of medium sand is 3.7-4.0, and the fineness modulus of fine sand is 1.4-1.7.

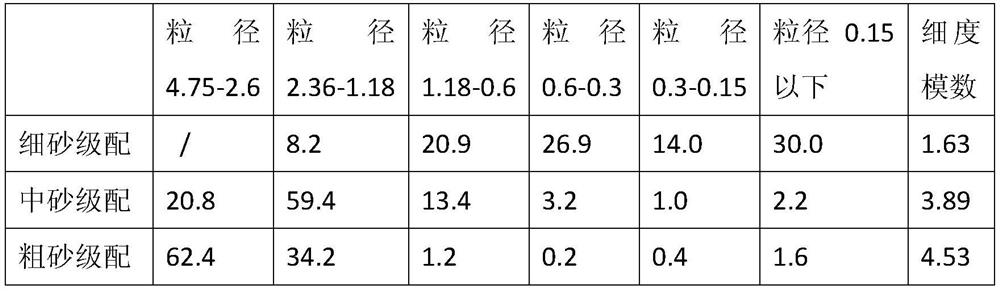

[0035] Specifically, according to the gradation method of machine-made sand for dry-mixed mortar of the present invention, the gradation design of machine-made sand is shown in Table 1 below:

[0036] Table 1 Gradation design of machine-made sand (particle size unit: mm)

[0037]

[0038] Among them, the fine sand gradation below 0.15 has a powder content of 26% to 32%.

Embodiment 2

[0039] Embodiment 2, the preparation and performance detection of admixture

[0040] The admixture used in the present invention is prepared from cellulose ether, vinyl acetate homopolymer powder (PVAC), starch ether, polysiloxane, and polycarboxylic acid in a ratio of 50:32:1.4:12.6:4.

[0041] Preparation method: Take 50 parts of cellulose ether, 32 parts of vinyl acetate homopolymer powder (PVAC), 1.4 parts of starch ether, 12.6 parts of polysiloxane, and 4 parts of polycarboxylic acid, put them into the mixer and mix them for 30 minutes, then pack them in 25Kg Bag and ready to use.

[0042] The admixture of the present invention (experimental group) and the conventional single admixture HPMC (control group) were used to prepare dry-mixed mortar. Except for the admixture, the other components and dosages of the two dry-mixed mortars DPM5 were the same. The performance comparison of the two mortars is shown in Table 4 below.

[0043] Table 4 Performance comparison of dry-m...

Embodiment 3

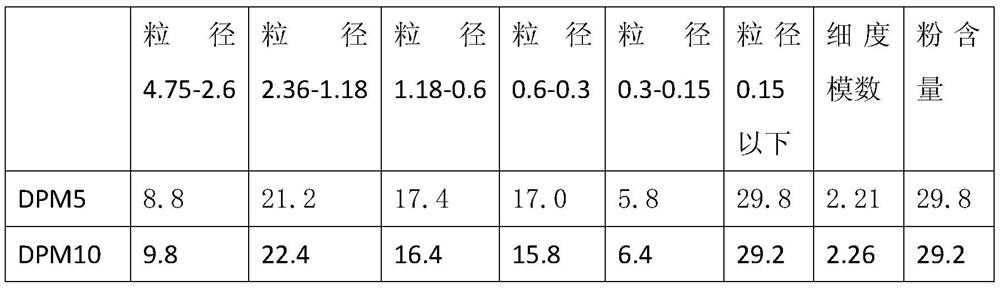

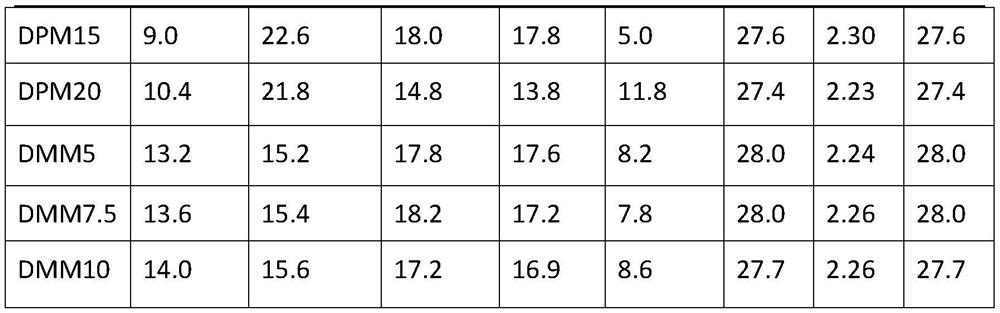

[0046] Embodiment 3, different types of dry-mixed mortar formulations and properties prepared by the inventive method

[0047] The formula is shown in Table 2. The machine-made sand used in each type of dry-mixed mortar adopts the gradation in Table 1 of Example 1, and the admixture in Example 2 is used as the admixture.

[0048] Table 2 Formulas of different types of dry-mixed mortar (unit: kg)

[0049] cement fly ash coarse sand Middle sand fine sand Admixture DMM5 100 50 210 40 600 0.37 DMM7.5 110 50 290 / 550 0.39 DMM10 130 50 310 / 510 0.40 DPM5 110 50 / 410 430 0.40 DPM10 130 50 / 430 390 0.44 DPM15 150 50 / 450 350 0.48 DPM20 170 50 / 470 310 0.50

[0050] Among them, the preparation of plastering mortar (DPM) first determines the amount of cement and fly ash in the plastering mortar according to the test ratio. The powder content of the particle size below 0.15 is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com