Automatic grinding machine for arc-shaped corner of chair backrest

A kind of grinding machine and arc-shaped technology, which is applied to the parts of grinding machine tools, machine tools and grinding machines suitable for grinding the edge of workpieces, etc. It can solve the problems of uneven grinding of backrest arc angles, reduce the cleaning burden and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

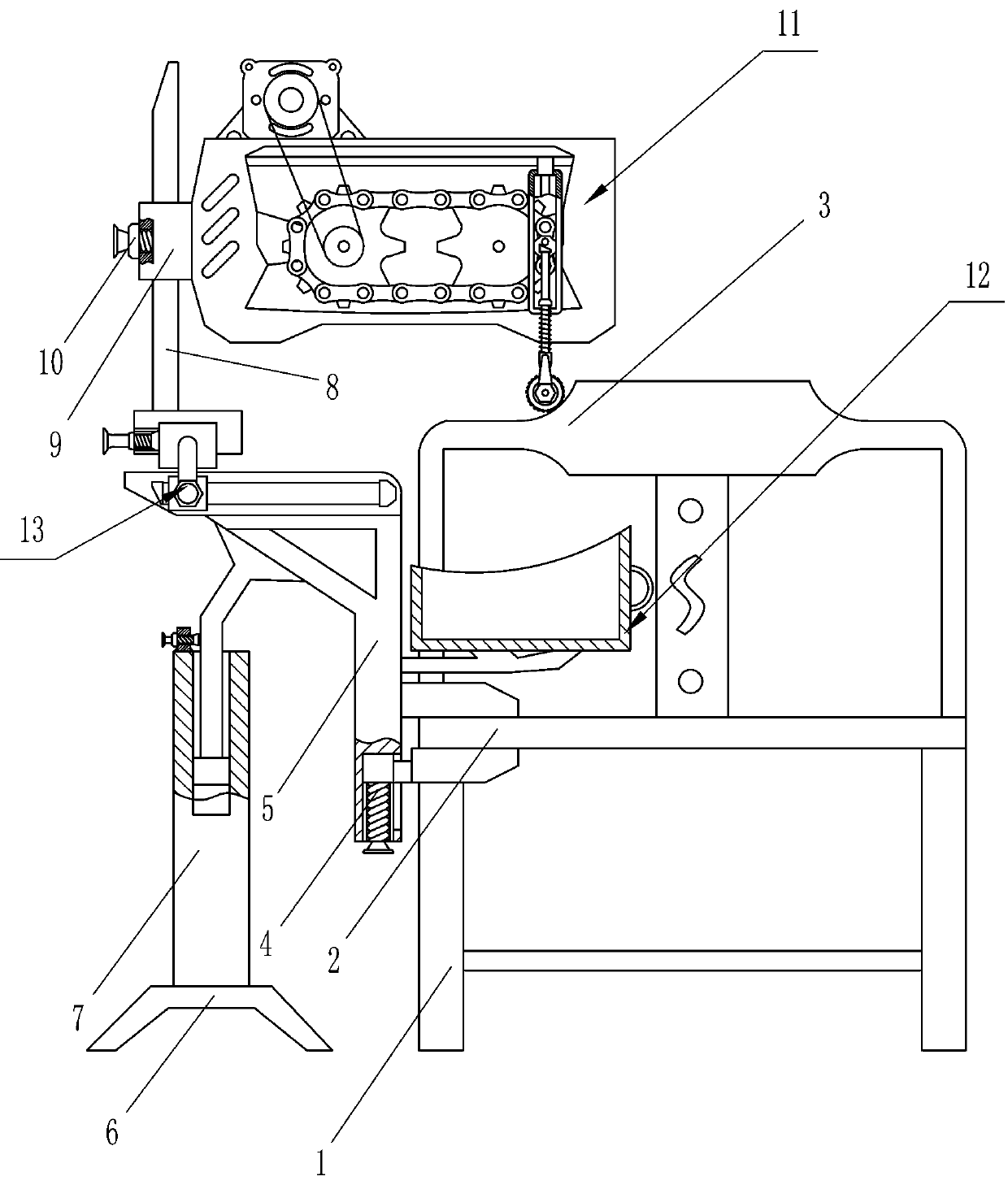

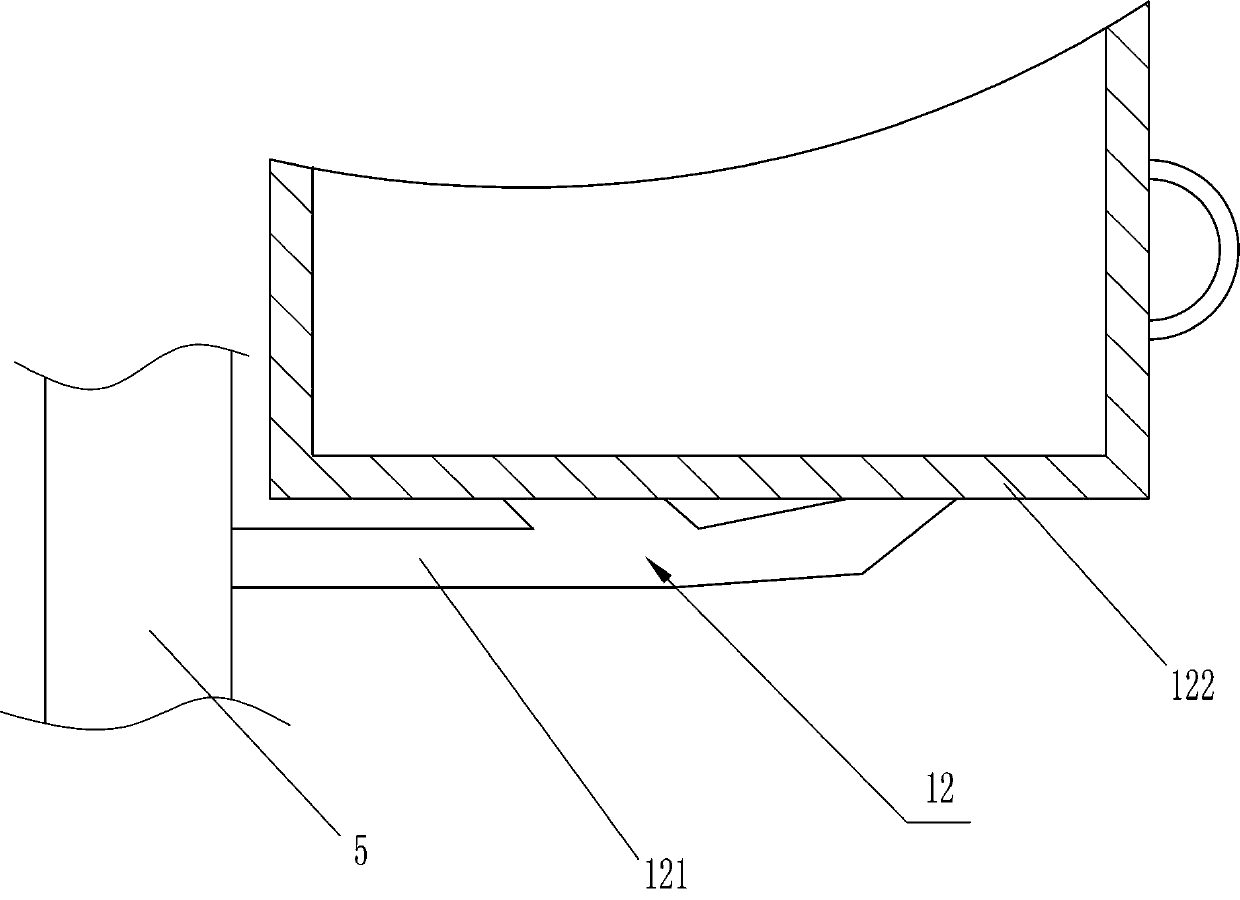

[0029] An automatic grinding machine for arc angles of chair backs, such as Figure 1-6 As shown, it includes a fixing assembly 4, a first support 5, a second support 6, a support device 7, a first slide bar 8, a first sliding sleeve 9, a first fastener 10, a polishing device 11 and an adjustment device 13. The top of the second support 6 is provided with a support device 7, the top of the support device 7 is welded with the first support 5, and the lower part of the right side of the first support 5 is installed with a fixing assembly 4, which can clamp the chair bottom plate 2 Tight, the top of the first support 5 is equipped with an adjustment device 13, the top of the adjustment device 13 is fixedly connected with a first slide bar 8, and the first slide bar 8 is slidably provided with a first sliding sleeve 9, and the left side of the first slide sleeve 9 The rotary type is provided with a first fastener 10 , the right end of the first fastener 10 is in contact with the l...

Embodiment 2

[0032] An automatic grinding machine for arc angles of chair backs, such as figure 1 , figure 2 and Figure 5 As shown, the supporting device 7 includes a third support 71, a second sliding block 72, a pole 73, a first fixing block 74 and a second fastening assembly 75, and a third support is fixed in the middle of the top of the second support 6. Seat 71, the third support 71 upper sliding type is provided with second slide block 72, and the top of second slide block 72 is provided with pole 73, and the top of pole 73 is welded with first support 5, and the top of third support 71 A first fixed block 74 is installed on the left side, and a second fastening assembly 75 is rotatably arranged inside the first fixed block 74 , and the right end of the second fastening assembly 75 is in contact with the left side of the strut 73 .

[0033] The fixed assembly 4 includes a first clamping plate 41, a first slide block 42, a second clamping plate 43 and a screw mandrel 44. The lowe...

Embodiment 3

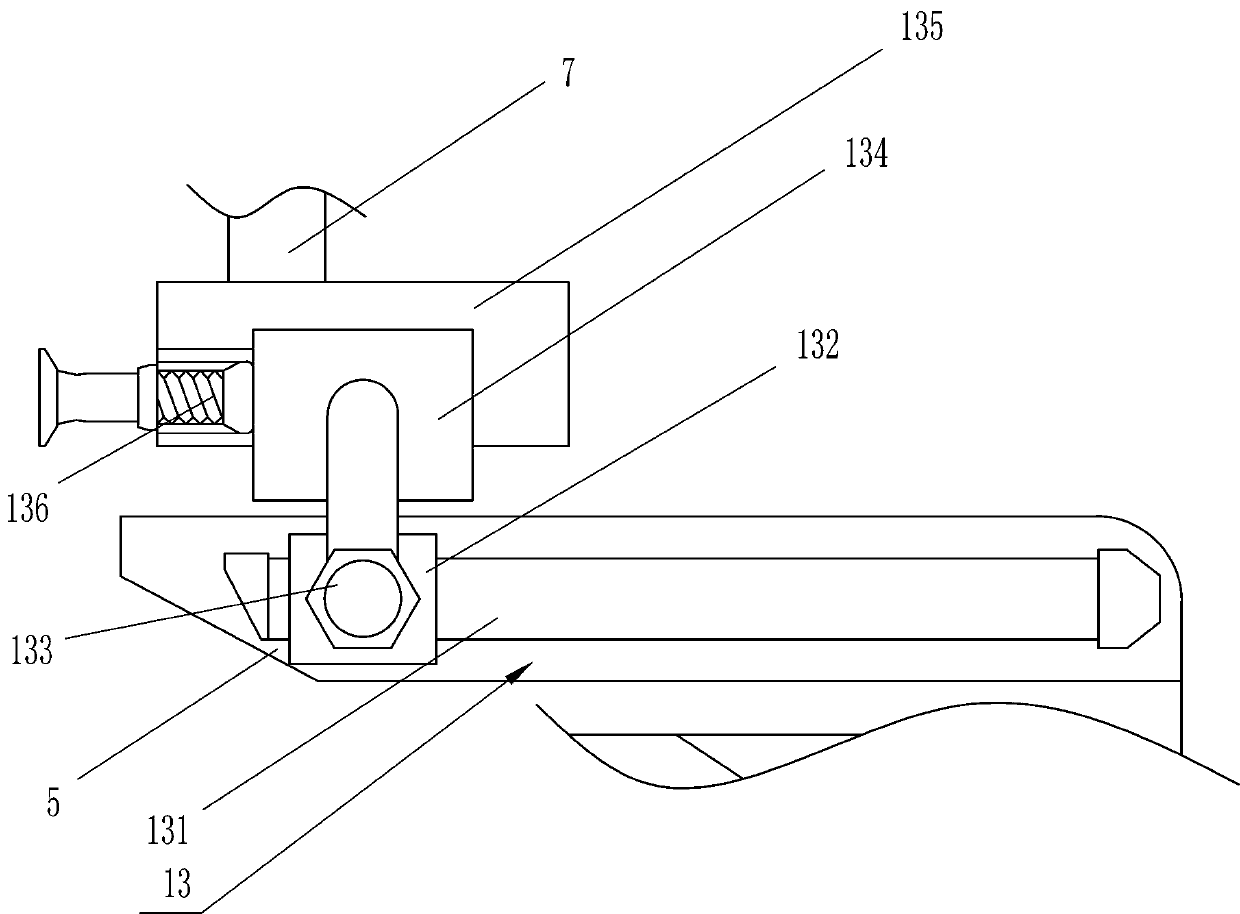

[0037] An automatic grinding machine for arc angles of chair backs, such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the adjusting device 13 includes a fourth sliding rod 131, a third sliding sleeve 132, a third fastener 133, a fifth sliding rod 134, a fourth sliding sleeve 135 and a fourth fastener 136, the first support 5 The top is fixedly connected with the fourth sliding rod 131, and the third sliding sleeve 132 is slidably arranged on the fourth sliding rod 131, and the third fastener 133 is installed through the middle part of the front side of the third sliding sleeve 132, and the third fastener The rear end of 133 is in contact with the front side of the fourth slide bar 131, the top of the third slide sleeve 132 is fixedly connected with the fifth slide bar 134, the fifth slide bar 134 is slidably provided with the fourth slide sleeve 135, the fourth slide sleeve 135 A fourth fastener 136 is provided through and rotated on the left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com