Urea solution continuous online batching system and solid feeding assembly thereof

A batching system and material feeding technology, which is applied in the direction of mixer accessories, dissolvers, mixers, etc., can solve the problems of high construction cost, limited layout location, and large volume of preparation equipment, so as to save equipment costs and reduce land occupation area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

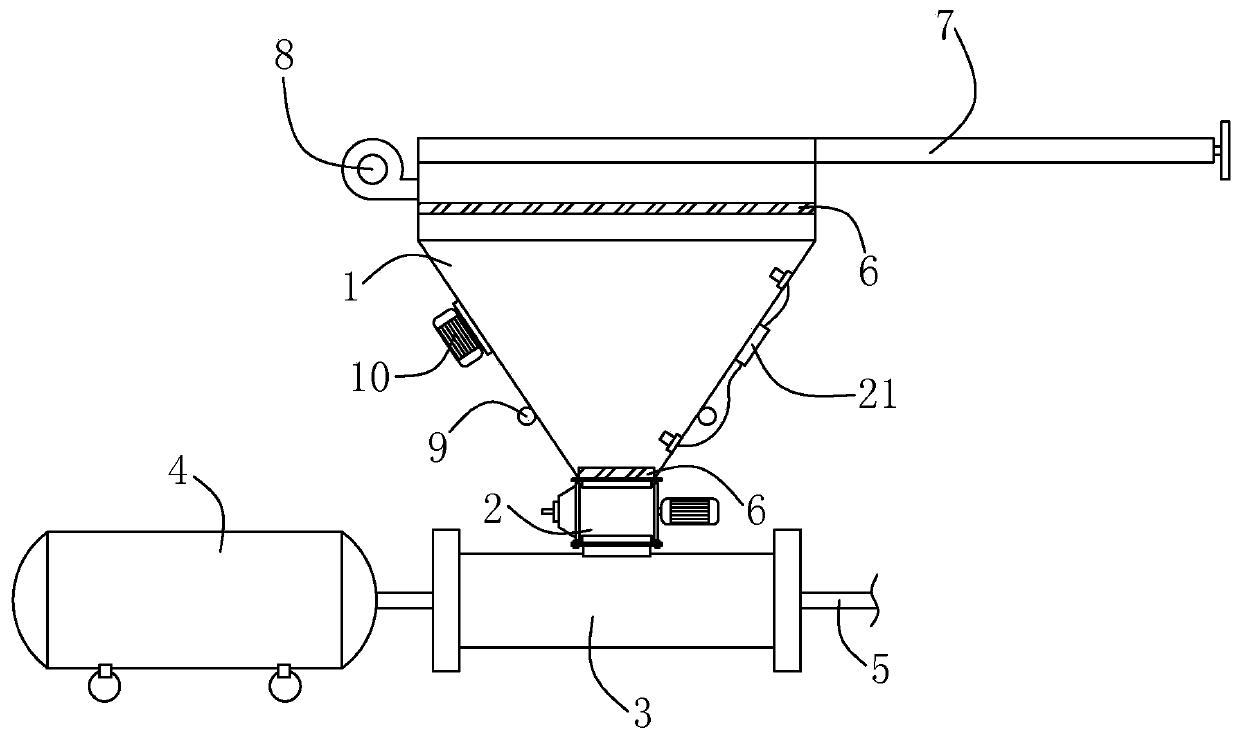

[0035] Such as figure 1 As shown, the present embodiment provides a solid feed assembly for continuous feeding, including a hopper 1 and a feed amount detector. The feed amount detector used in this embodiment is a level gauge 21, which is located in the hopper Two probes are set in 1, one is located at the upper position of hopper 1 to detect the upper limit of material feeding, and the other is located at the lower position of hopper 1 to detect the lower limit of material feeding. When the material in hopper 1 reaches the upper limit of feeding, stop feeding to prevent the material from overflowing from hopper 1; when the material in hopper 1 reaches the lower limit of feeding, stop the operation of rotary feeder 2 to ensure that the rotary feeder 2 The urea is of fixed capacity (not empty). There are two layers of filter screens 6 fixedly connected in the hopper 1, one layer is located near the top of the hopper 1, and the other side is located at the bottom of the hopper...

Embodiment 2

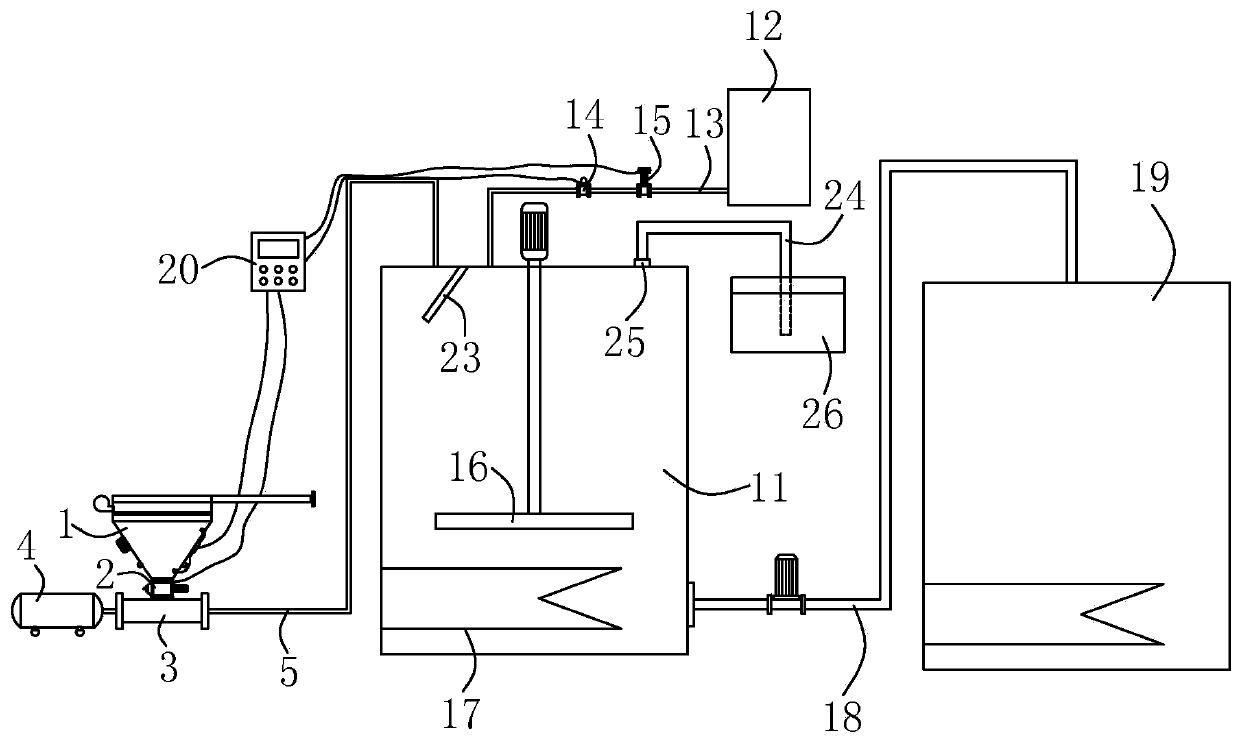

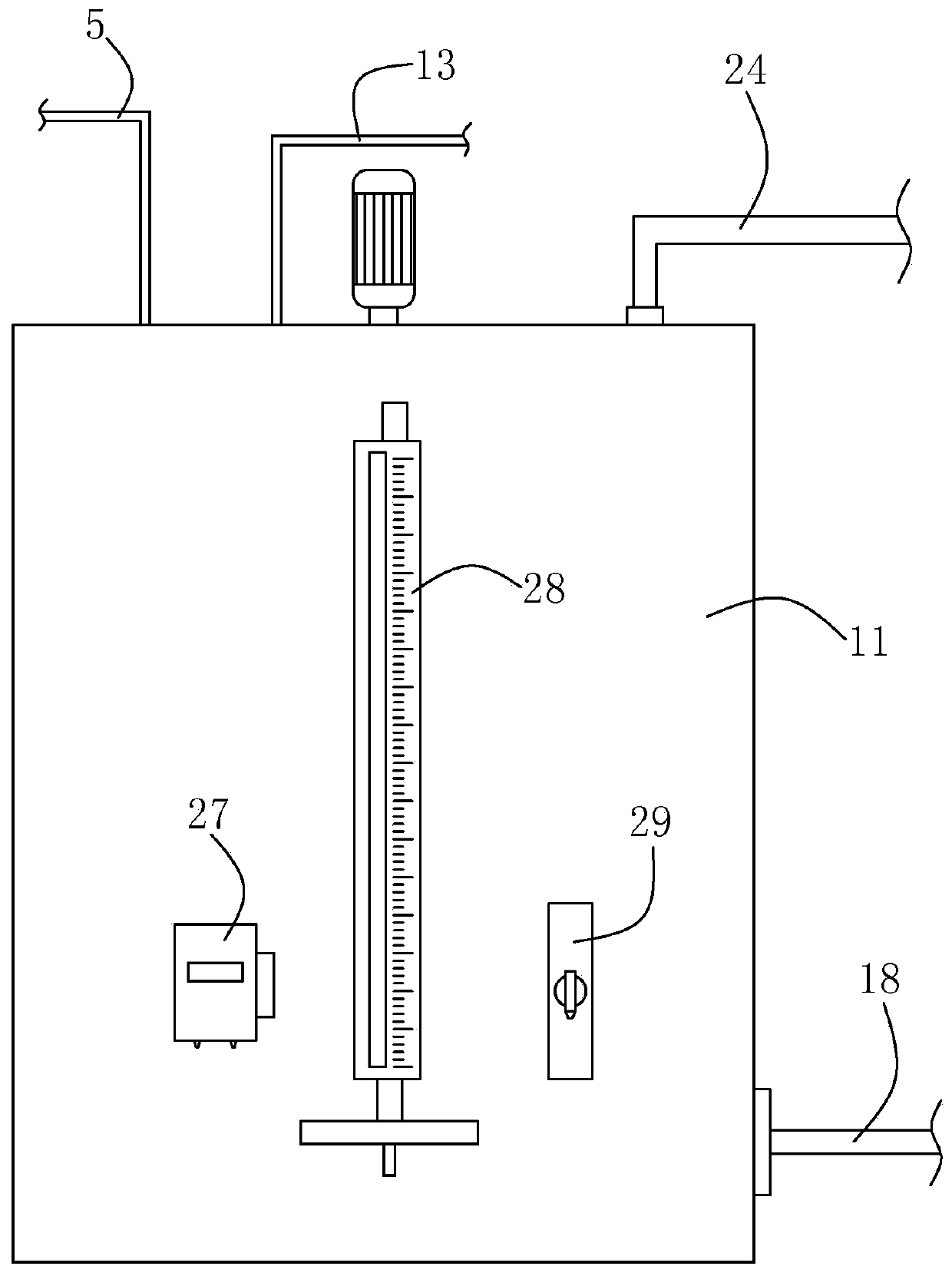

[0039] Such as figure 2 As shown, the present embodiment provides a continuous online batching system for urea solution, including a batching tank 11, the batching tank 11 is fixedly connected with the solid feed assembly of Embodiment 1, that is, one end of the feed pipe 5 and the gas-solid mixer 3 Fixedly connected, the other end is fixedly connected with the top of the batching tank 11, so that the material enters the batching tank 11 along the feed pipe 5 along with the airflow. A deflector 23 is fixedly connected to the position communicating with the feed pipe 5 in the batching tank 11. The deflector 23 used in this embodiment is a deflector, and the deflector is fixed to the connection of the feed pipe 5 in an oblique shape. place. In this way, when feeding, the airflow entraining urea particles impacts on the deflector, and the urea particles fall along the deflector into the batching tank 11, and the airflow moves upward under the obstruction of the deflector, which...

Embodiment 3

[0045] The difference between this embodiment and embodiment two mainly lies in: Figure 4 As shown, the feed amount detector of this embodiment adopts a solid flow meter 22, which is fixedly connected to the feed pipe 5, and the feed amount of urea particles is monitored by the solid flow meter 22. The solid flow meter 22, the water flow meter 14 and the regulating valve 15 are respectively electrically connected to the controller 20. When the feed amount transmitted by the solid flow meter 22 and the water flow meter 14 to the controller 20 does not meet the preset ratio, the controller 20 An instruction is sent to the regulating valve 15, and the regulating valve 15 is controlled to increase or decrease the water flow, so that the urea granules and water are fed synchronously according to the preset ratio. A reserved interface is provided on the feed pipe 5 between the solid flow meter 22 and the gas-solid mixer 3, and the reserved interface can be used to connect a tank tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com