Horizontal linear vibration motor and implementation method thereof

A vibration motor, horizontal linear technology, used in electrical components, electromechanical devices, etc., can solve problems such as unfavorable product performance stability, use in harsh temperature conditions, and huge differences in damping states, reducing quality factor and stopping time, and large eddy current loss. , the effect of shortening the stop time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

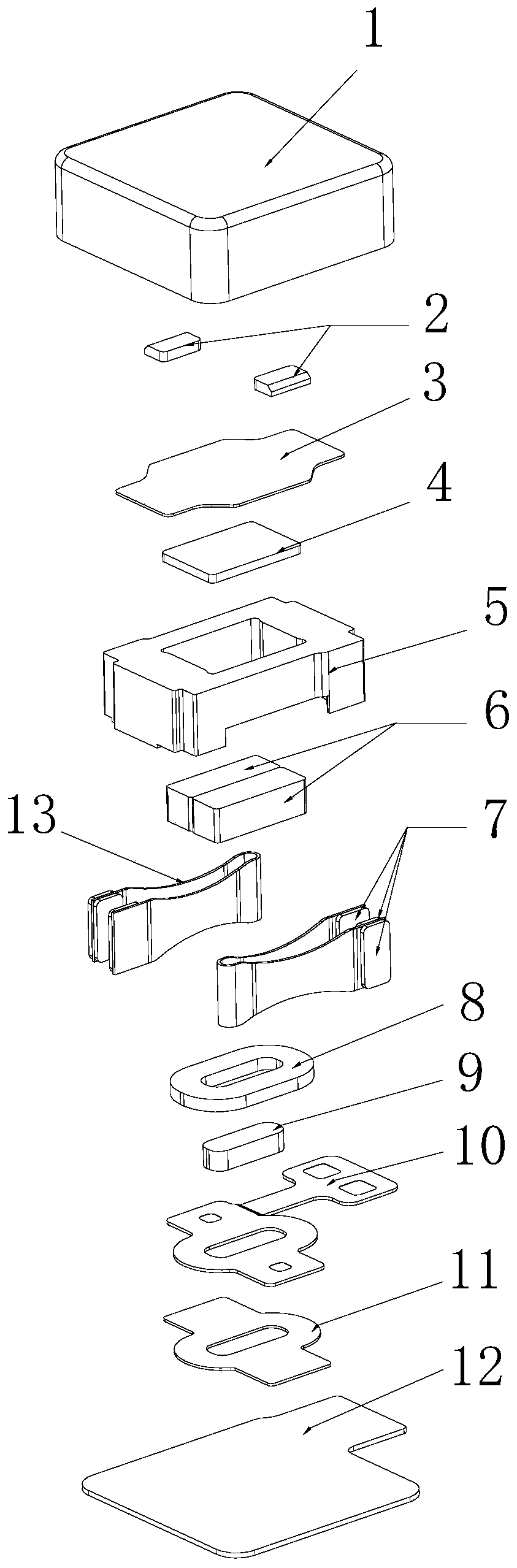

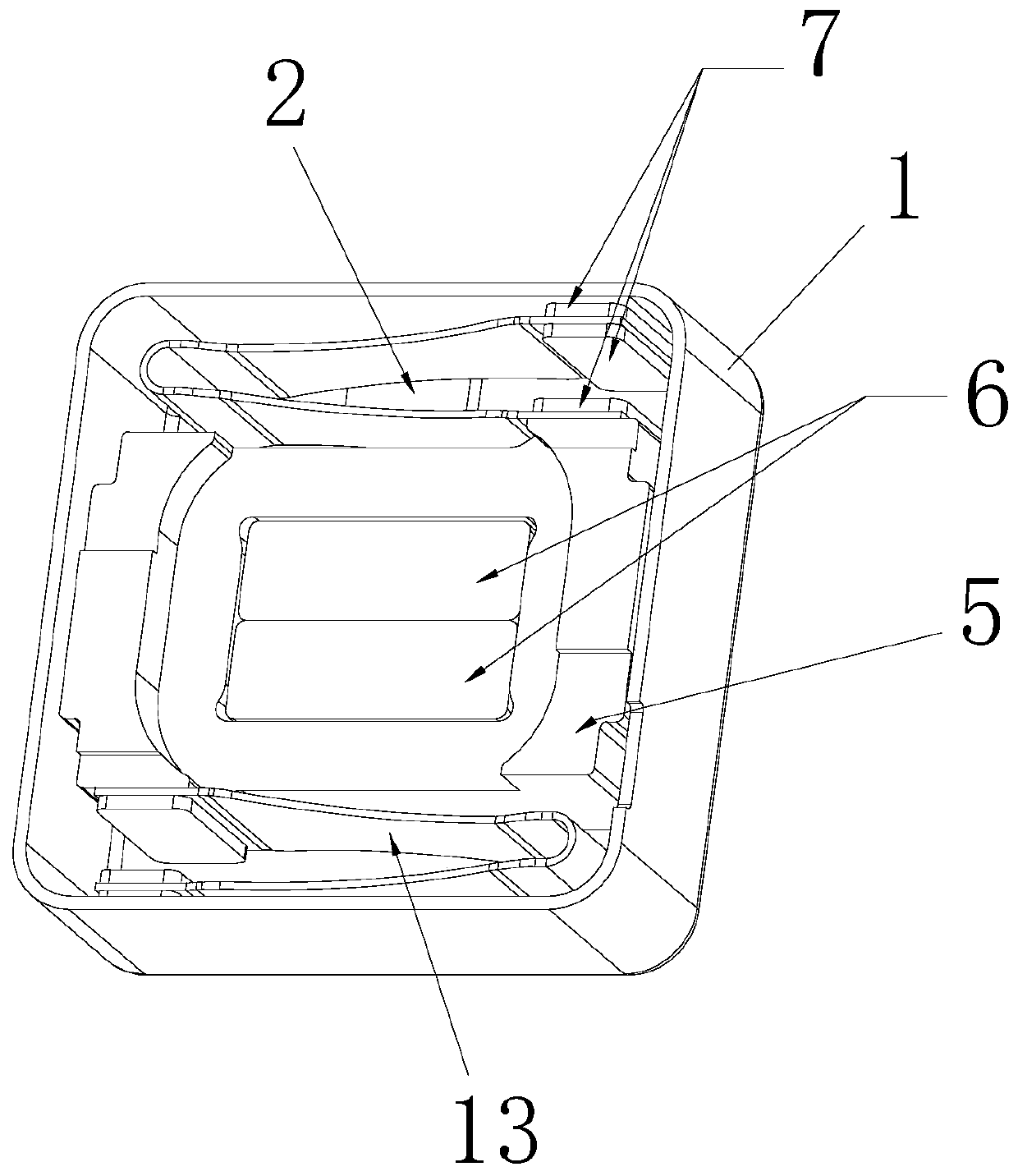

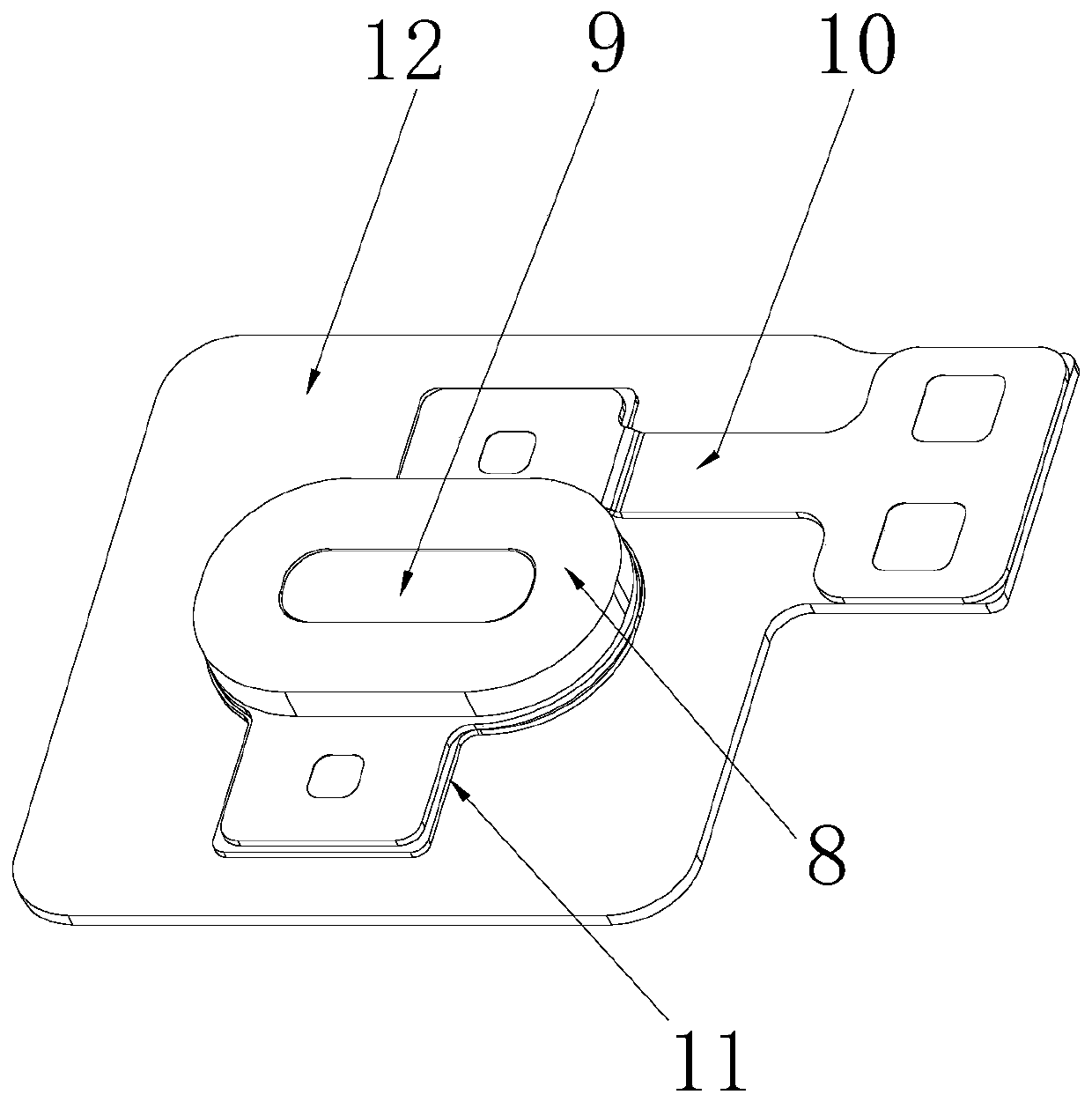

[0037] see Figure 1-5 , the present invention provides the following technical solutions: a horizontal linear vibration motor, including a casing 1, a lower cover 12 is connected below the casing 1, a stator assembly is connected above the lower cover 12, and a vibrator is arranged above the stator assembly Assemblies, the two sides of the vibrator assembly are connected to the casing 1 through the spring piece 13, the stator assembly includes the coil 8, the iron core 9, the FPC circuit board 10 and the damping plate 11, wherein the damping plate 11, the FPC circuit board 10 and the coil 8 from The coil 8 is electrically connected to the FPC circuit board 10, and the iron core 9 is arranged inside the damping plate 11, the FPC circuit board 10 and the coil 8. The vibrator assembly includes a counterweight 5. The inside of the counterweight 5 is provided with two magnets 6 arranged side by side, and the inside of the counterweight 5 is provided with a cavity for accommodating...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that further, the two sides of the connecting arm connecting the spring leaf 13 to the casing 1 and the side of the connecting arm connected to the counterweight 5 and away from the counterweight 5 are respectively connected. There is stopper 7.

[0054] By adopting the above-mentioned technical solution, the stopper 7 converts the fixing method from point fixing (welding) to surface fixing (surface bonding), so as to ensure the smooth operation of the spring leaf 13 during work, and also provide space for the deformation of the spring leaf 13.

[0055] Further, the implementation method of the horizontal linear vibration motor according to the present invention includes the following steps:

[0056] (1) The casing 1 and the lower cover 12 form a closed cavity for accommodating the vibrator assembly and the stator assembly inside;

[0057] (2) The vibrator assembly is mainly composed of a counterweight 5, a bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com