Carbon-coated nickel selenide ultrathin nanosheet composite material and preparation method thereof

A technology of composite materials and carbon nanosheets, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor conductivity, poor cycle performance, low reversibility, etc., to improve conductivity , avoid stacking, alleviate the effect of volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

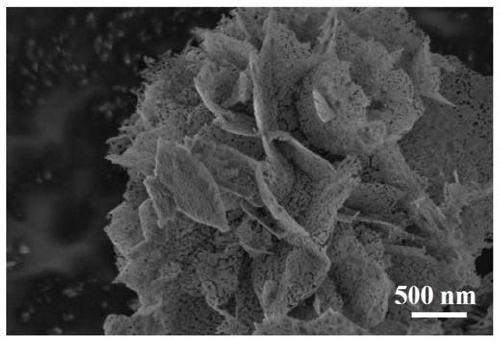

[0030] (1) Preparation of three-dimensional flower-like Ni(bim)(2-mim) precursor

[0031] 300 mg of nickel nitrate hexahydrate was dissolved in 20 mL of ethanol solution to form solution A. 830 mg of benzimidazole was dissolved in 20 mL of ethanol solution to form solution B. Solution C was formed by dissolving 830 mg of 2-methylimidazole into 20 mL of ethanol solution. Solution C was added dropwise to solution A under ultrasonication to form solution D. Then, solution B was added dropwise to solution D, stirred rapidly at room temperature for 30 minutes, washed with absolute ethanol three times, and dried in a blast drying oven at 120°C for 24 hours to obtain Ni(bim)(2-mim) .

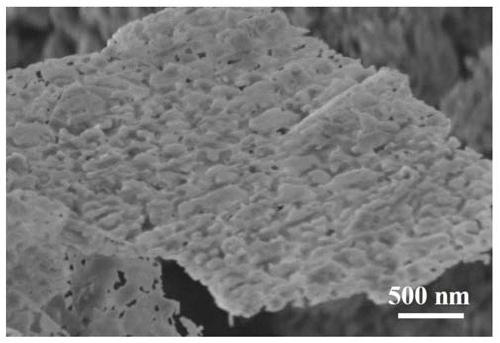

[0032] (2) Preparation of carbon-coated nickel selenide NiSe@C

[0033] Take 200mg of Ni(bim)(2-mim) precursor and selenium powder and grind them evenly at a mass ratio of 1:2, and spread them on a porcelain boat. Calcination is then carried out under a pure argon atmosphere, the calcination tempe...

Embodiment 2

[0047] The difference from Example 1 is that the mass ratio of benzimidazole (830 mg) to 2-methylimidazole in step (1) is 1:2. The calcination temperature in step (2) is 650° C., and the yield of the obtained product is 60%. Test results: The three-dimensional nanoflower structure of NiSe@C is destroyed, and it is difficult to find a complete three-dimensional nanoflower structure. The thickness of the broken carbon sheet is about 15nm, and there are a large number of mesopores and macropores. Broken 3D nanoflowers cannot effectively suppress the volume expansion of NiSe, resulting in poor cycling stability.

Embodiment 3

[0049] The difference from Example 1 is that the mass ratio of benzimidazole (830 mg) to 2-methylimidazole in step (1) is 6:1. The calcination temperature in step (2) is 650° C., and the yield of the obtained product is 68%. Test results: NiSe@C is stacked by carbon nanosheets of different thicknesses, the thickness is about 30nm-50nm, no three-dimensional nanoflower structure is found, and there are a lot of micropores. Too thick carbon nanosheets are not conducive to the transport of Na ions, resulting in low specific capacity and poor rate performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com