Crop warm-drying room

A crop and drying room technology, which is applied in the field of crop processing devices, can solve the problems that the shape and color of plants are not fresh, and the cost of freeze-drying is high, and achieves the effects of high commodity grade, overcoming high cost, and bright color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

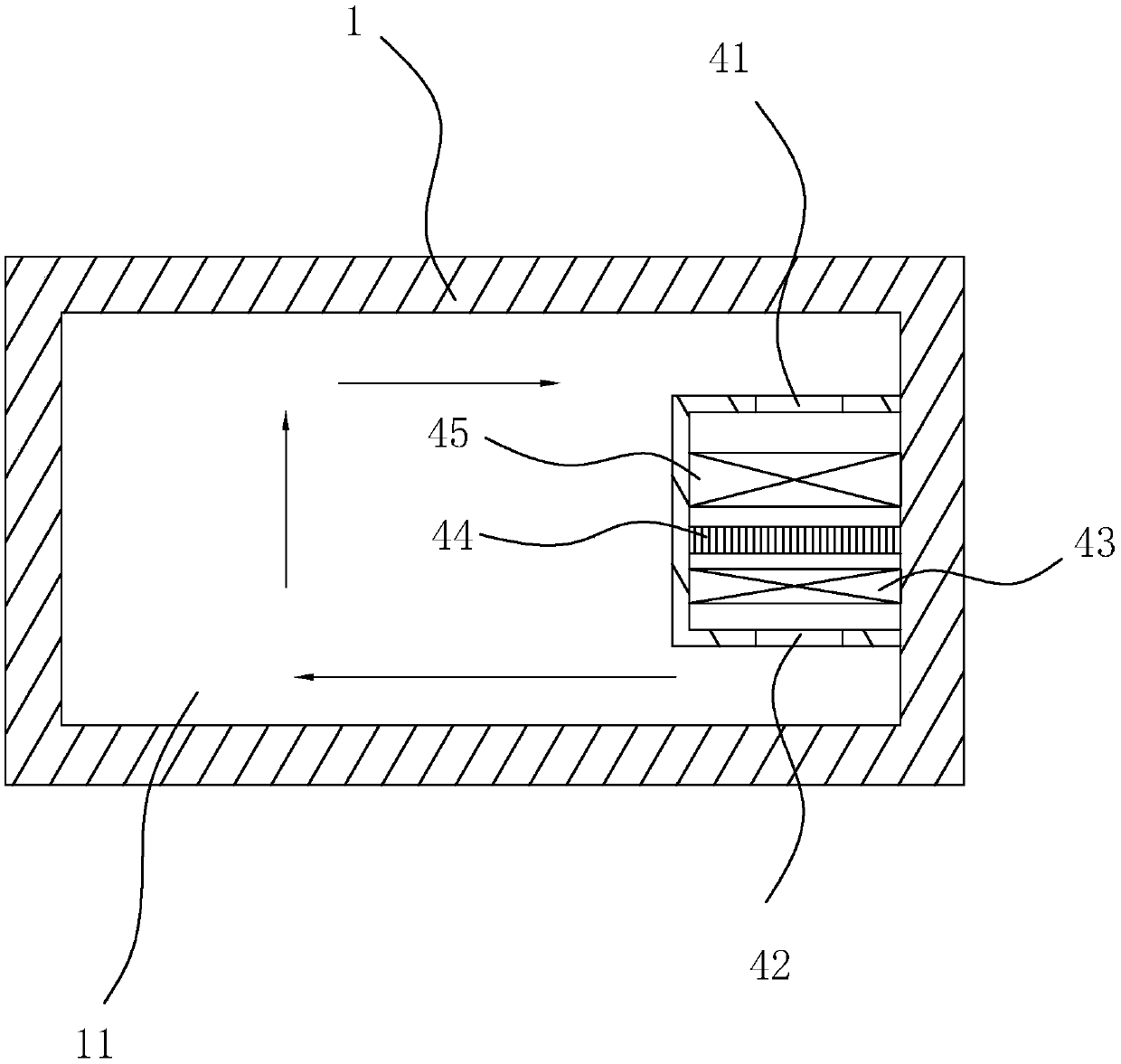

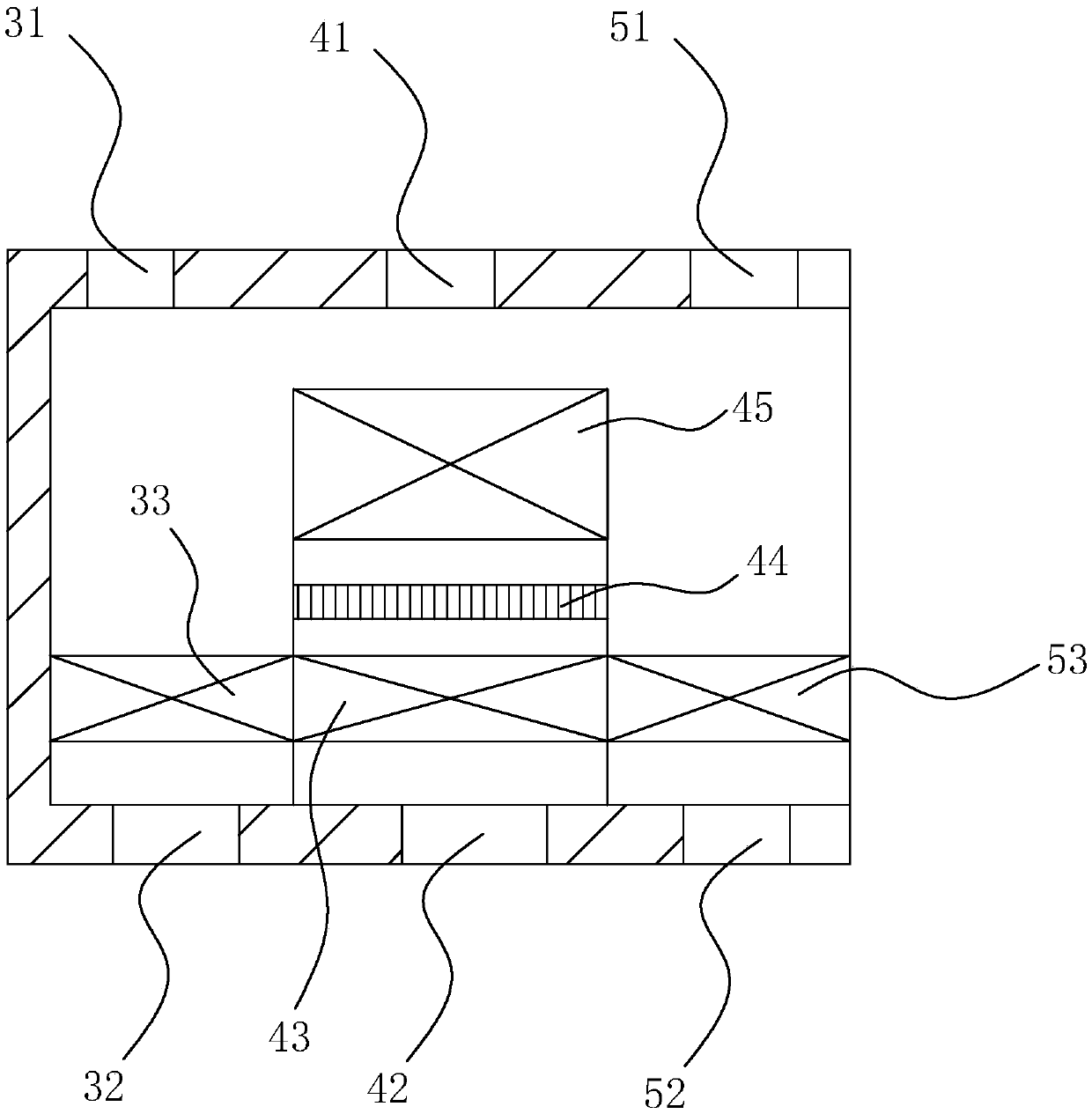

[0025] A crop temperature drying room, such as figure 1 As shown, the crop temperature and drying room 1 is included, and the crop temperature and drying room 1 is provided with a door body in a closed space, and the crop temperature and drying room 1 is provided with a crop temperature and drying room 11 and a foehn manufacturing mechanism; the foehn manufacturing mechanism includes an air inlet, The air outlet and the cooling and drainage structure, heating device and fan arranged between the air inlet and the air outlet; the foehn manufacturing mechanism is equipped with several groups, and the dry hot air is used to warm and dry the crops, and the dehydrated crops in this way , Moisture is discharged in the form of water, which can complete the purpose of drying and dehydration at a lower temperature, avoid high temperature burning of crops, change the nutrient content of crops, and control it to imitate the natural temperature and the best drying wind speed in nature.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com