Anti-loosening connecting bolt

A technology for connecting bolts and anti-loosening, which is applied in the direction of bolts, connecting components, screws, etc. It can solve the problems of not installing anchor bolts, poor anti-loosening reliability, and unfavorable mass application, etc., to achieve long service life and high reliability , beneficial to the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

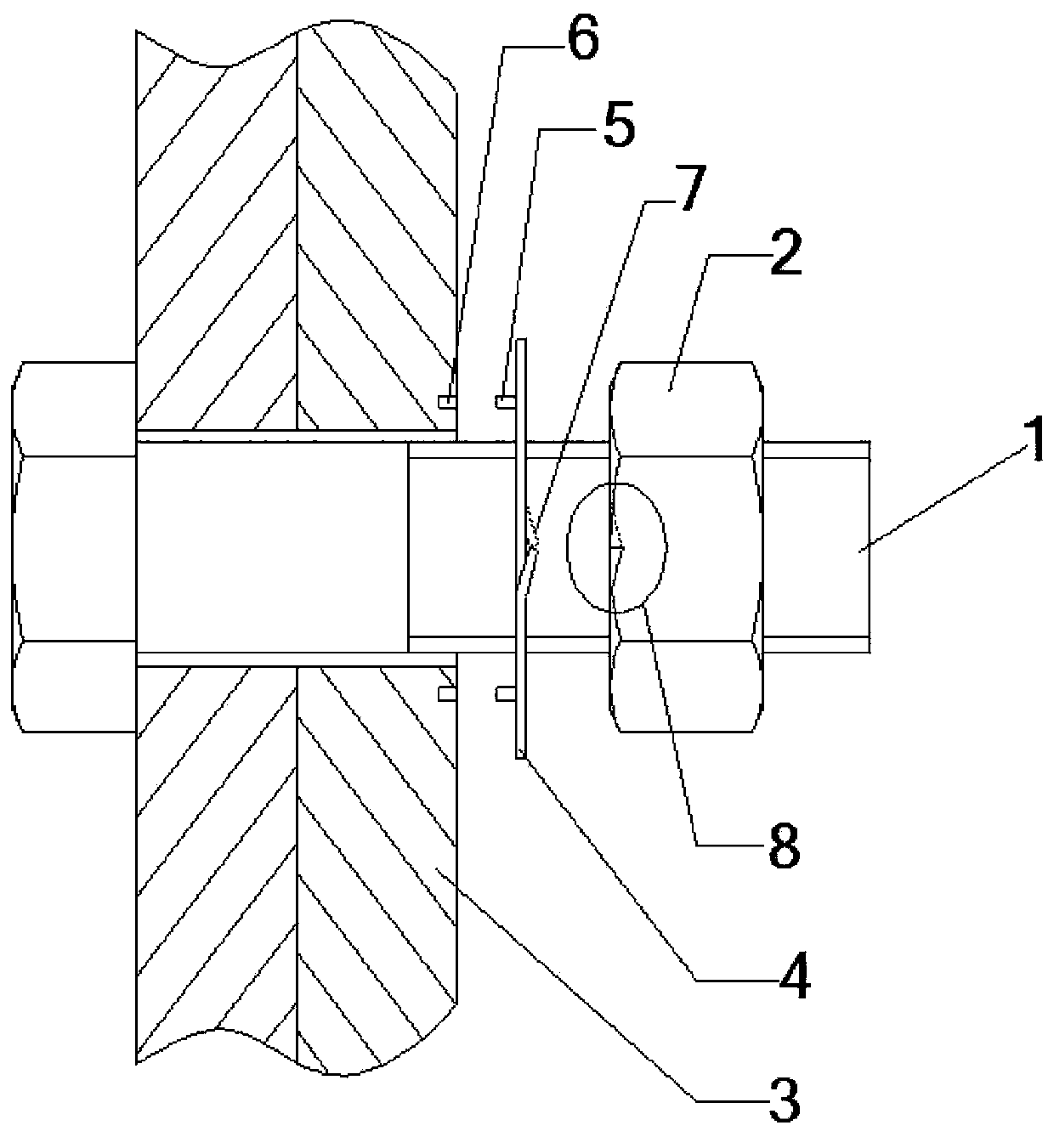

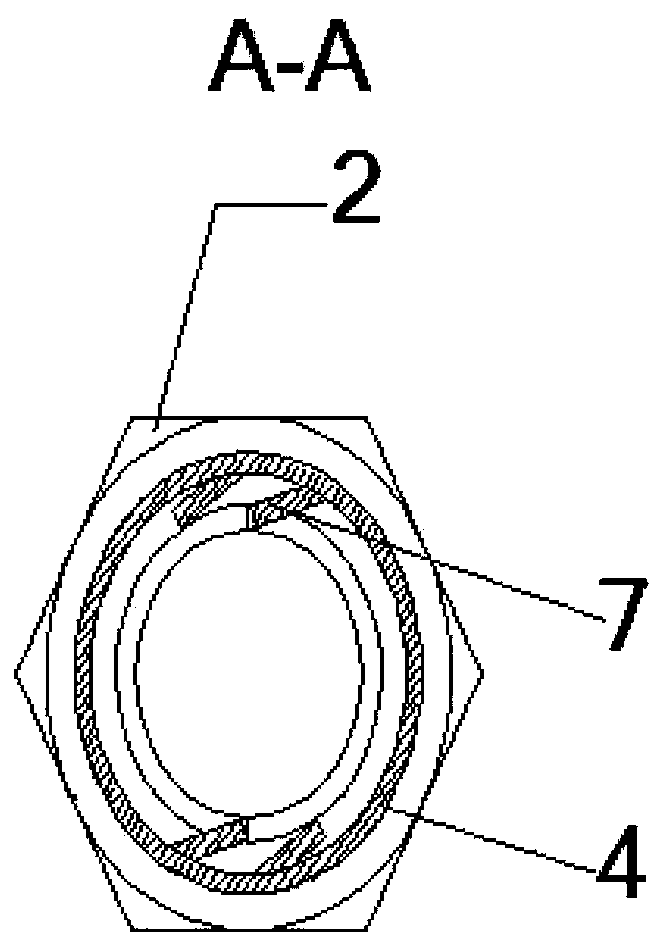

[0052] Embodiment one, see figure 1 , the anti-loosening connecting bolts include a bolt 1 and a nut 2 connected to the joint surface part 3, and it is characterized in that at least one V-shaped groove 8 is provided at the joint end surface of the nut 2 and the joint surface part 3; The bolt between the joint surface part 3 is also provided with a metal stop shrapnel 4; the side where the metal stop spring piece 4 contacts with the joint surface part 3 is provided with a stop boss 5; the joint surface part 3 is provided with a The groove 6 matched with the stop boss 5; the stop piece 7 is provided on the side where the metal stop shrapnel 4 is in contact with the nut 2 .

[0053] The V-shaped groove 8 is center-symmetric. Central symmetry means: when the number of V-shaped grooves is two or more. One end surface of the nut 2 is provided with a V-shaped groove 8 .

[0054] see Figure 4 , the bolt 1 is replaced by a screw, the surface where the head of the screw is in con...

Embodiment 2

[0055] Embodiment 2, referring to Fig. 2 (a) ~ (d), the anti-loosening connecting bolt includes a bolt 1 and a nut 2 connected to the joint surface part 3, and the radial direction of the bolt 1 body is arranged symmetrically along the bolt axis at least one There is a V-shaped groove 8; the threaded side of the nut 2 is provided with a metal stop shrapnel 4.

[0056] The metal stop spring 4 is arranged on the threaded side of the nut 2, which means that the metal stop spring 4 is a separate part, and the method of setting it on the thread side of the nut 2 is the same as that of the nylon ring of GB889.

Embodiment 3

[0057] Embodiment 3, referring to Fig. 3(a)-(e), the anti-loosening connecting bolt includes a bolt 1 and a nut 2 connected to the joint surface part 3, and the end surface of the bolt 1 is provided with a V-shaped groove 8; the nut 2 A metal stop shrapnel 4 is provided on the side facing the end face of the bolt 1; after the nut 1 rotates to determine the position, the stop piece 7 on the metal stop shrapnel 4 engages with the V-shaped groove 8.

[0058] The stop piece 7 on the metal stop elastic piece 4 is arranged on the end face side of the nut 2, see FIG. 3( a ). The metal stop shrapnel is an independent part, and it is arranged on the threaded side of the nut 2 in the same way as the nylon ring of GB889.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com