Lock nut and using method

A technology of anti-loosening nuts and internal nuts, which is applied in the direction of nuts, screws, bolts, etc., can solve the problems of difficult installation, difficult processing, equipment failure, etc., and achieve the effect of small occupied area, good anti-loosening effect and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

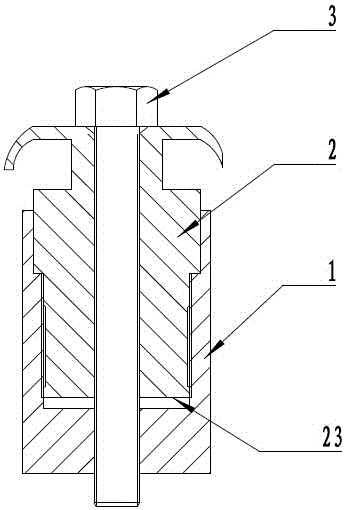

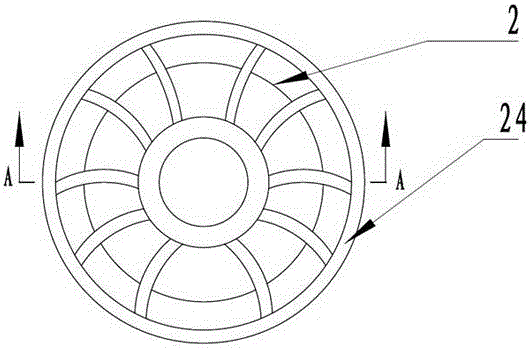

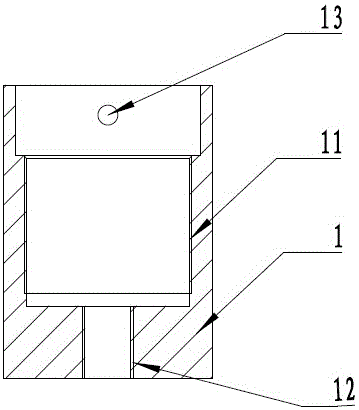

[0034] As shown in the accompanying drawings: a lock nut, including an outer nut 1 and an inner nut 2, the inner nut 2 is provided with a first internal thread 21, the lower end of the outer wall of the inner nut 2 is provided with an outer thread 22; There is a second internal thread 11 , and a third internal thread 12 is provided at the inner bottom of the outer nut 1 ; the inner nut 2 is installed in the outer nut 1 .

[0035] The direction of rotation of the external thread 1 is consistent with that of the second internal thread 11, and the direction of rotation of the external thread 22 is opposite to that of the first internal thread 21 and the third internal thread 12; The internal thread 11 is connected, and the bolt 4 is connected with the first internal thread 21 of the internal nut 2 and the third internal thread 12 of the external nut 1 .

[0036] Preferably, in this embodiment, the distance between the first plane 23 at the bottom of the inner nut 2 and the second...

Embodiment 2

[0045] Embodiment 2 is generally consistent with the implementation of Embodiment 1, the difference is that in Embodiment 2, the distance between the first plane 23 at the bottom of the inner nut 2 and the second plane 13 below the second internal thread 11 in the outer nut 1 is 2 times the pitch, the engagement length of the external thread 22 and the second internal thread 11 is 1.5 times the thread length of the third internal thread 12 .

[0046] Through the embodiments, it can be found that the present invention has the following characteristics compared with the prior art: 1. The present invention engages the forward and reverse threads after the bolts are tightened by hand, so that the bolts cannot be loosened, and the anti-loosening effect is good; 2. The structure is simple, and the Simple tightening of nuts and bolts can achieve anti-loosening; 3. Easy installation, the invention can be installed immediately after use, occupies a small area, and can be adapted accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com