Axial flow ventilator capable of synchronously adjusting blades

An axial flow fan, synchronous adjustment technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of unbalanced service life, time-consuming and labor-intensive impellers, etc., to extend service life, improve anti-corrosion performance, and reduce vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

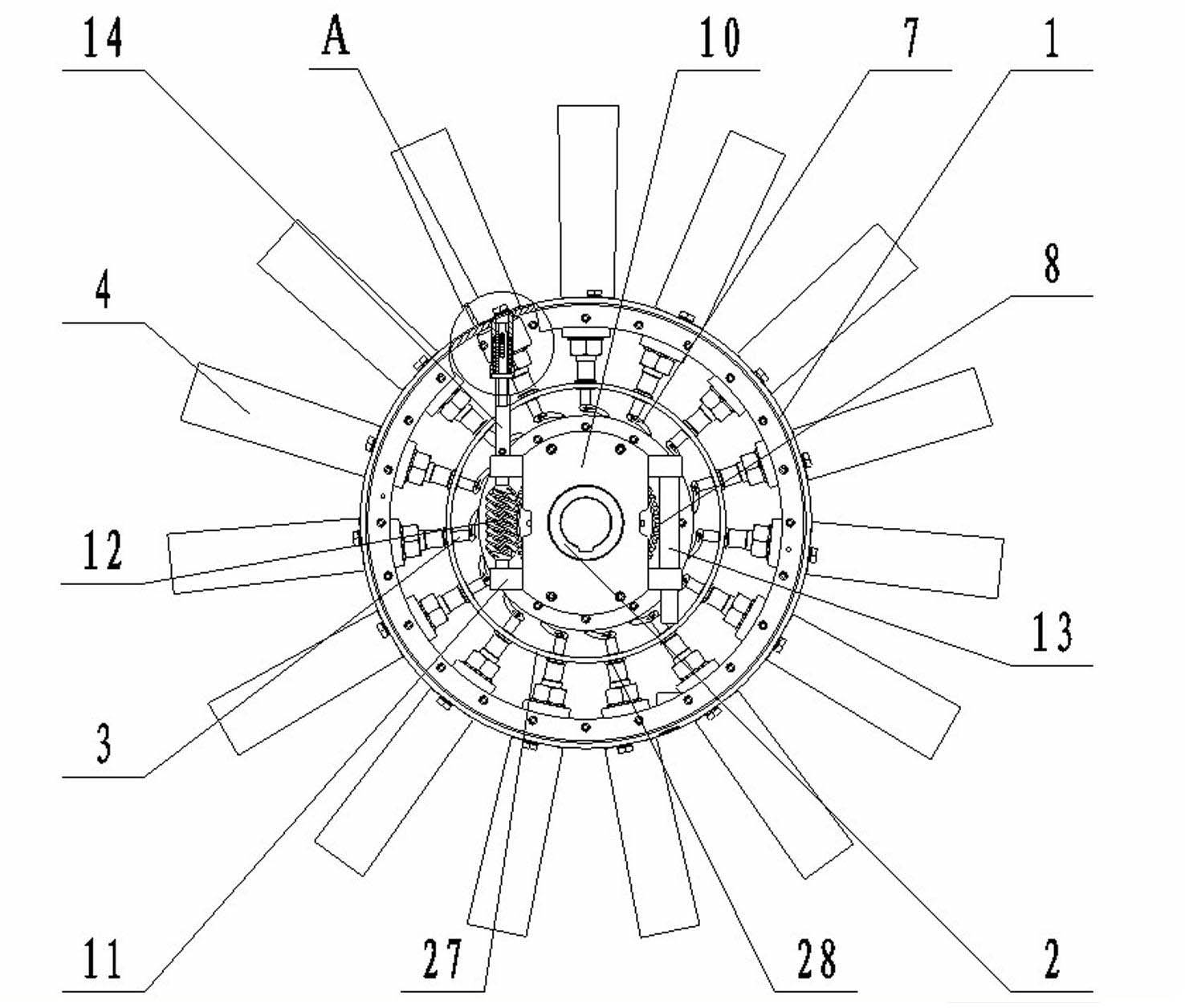

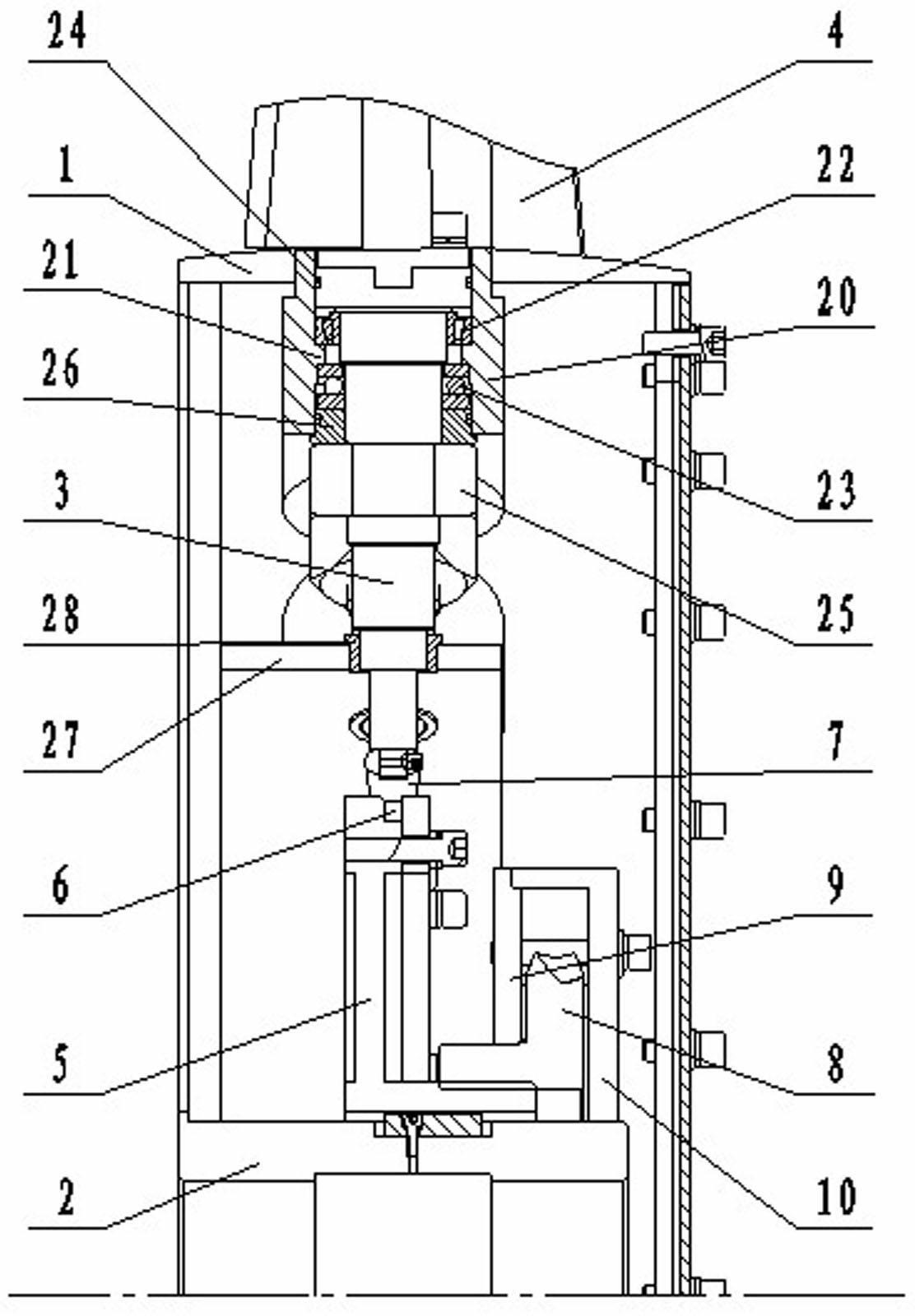

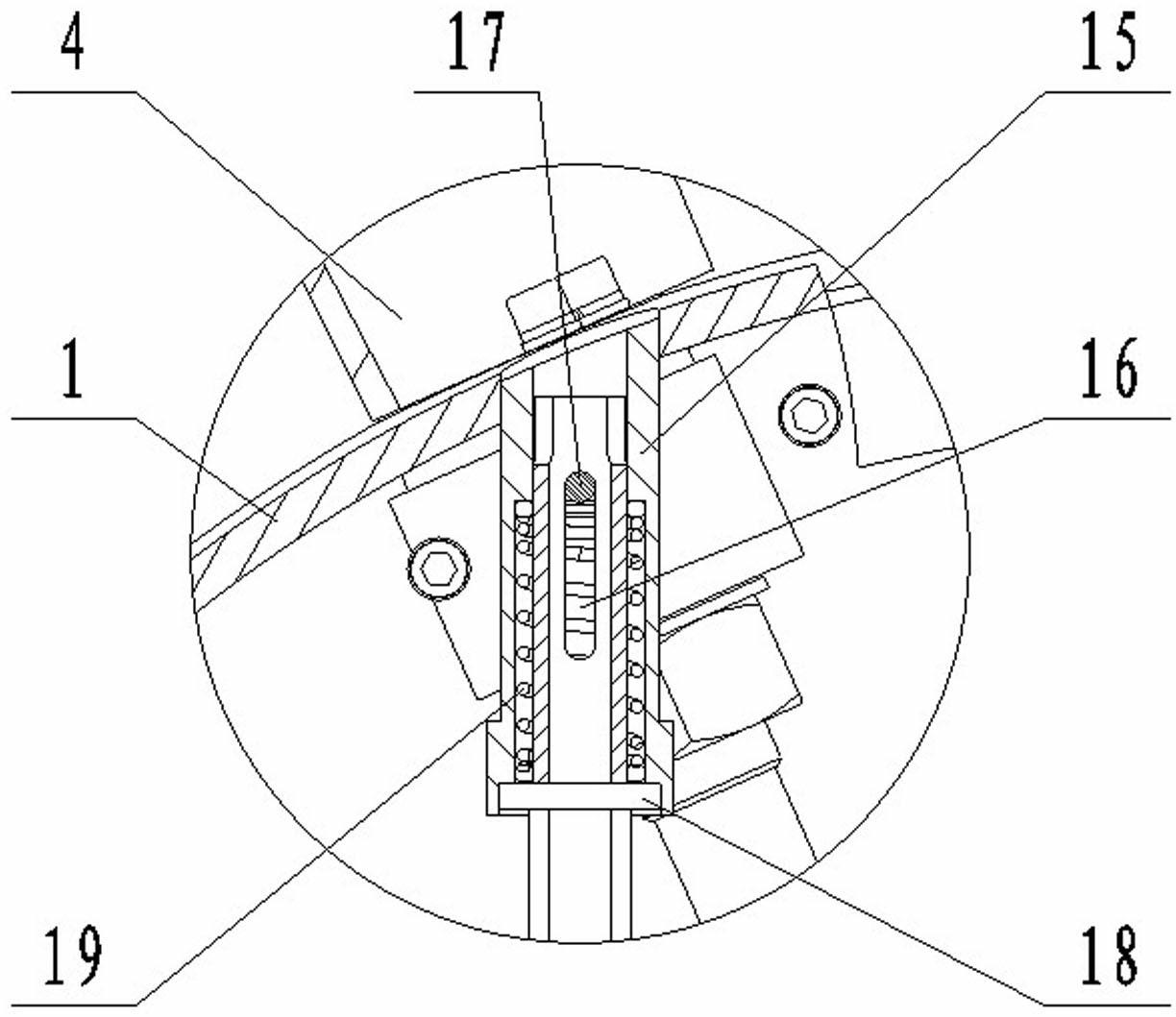

[0014] The blade synchronously adjusts the axial flow fan, including the hub 1 and the shaft sleeve 2 coaxial with it, the hub 1 is pierced with a number of radially arranged petioles 3, the outer ends of the petioles 3 are fixed with blades 4, and the shaft sleeve 2 is covered with left and right The push plate 5 that slides on it and protrudes from the middle part of the right end face has a circumferential groove 6 on the outer cylindrical surface of the push plate 5, and a crank 7 whose other end is hinged with the petiole 3 is placed in the groove 6, and the right end of the push plate 5 is The side is provided with a worm wheel 8 sleeved on the shaft sleeve 2, the inner hole of the worm wheel 8 is threaded with the outer cylindrical surface protruding from the middle part of the right end face of the push plate 5, and the outside of the left and right end faces of the worm wheel 8 is provided with a support seat 9 fixed with the shaft sleeve 2 and Cover plate 10, worm sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com