Method and system for determining paraffin removal period of oil well

A determination method and wax removal technology, which are used in cleaning tools, earth-moving drilling, wellbore/well components, etc., can solve the problems of reducing oil well productivity, affecting economic benefits, and poor wax removal effect, achieving strong practicability and efficiency. Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

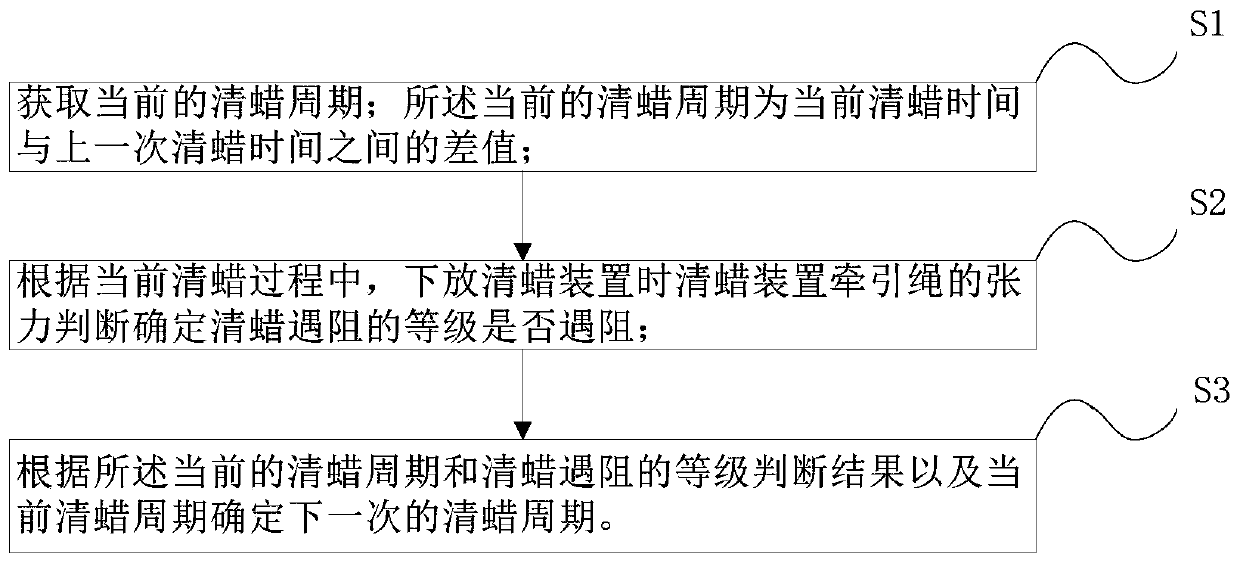

[0062] Such as figure 1 As shown, the method for determining the oil well wax removal cycle provided in this embodiment includes:

[0063] S1. Get the current wax removal cycle; the current wax removal cycle is the difference between the current wax removal time and the last wax removal time;

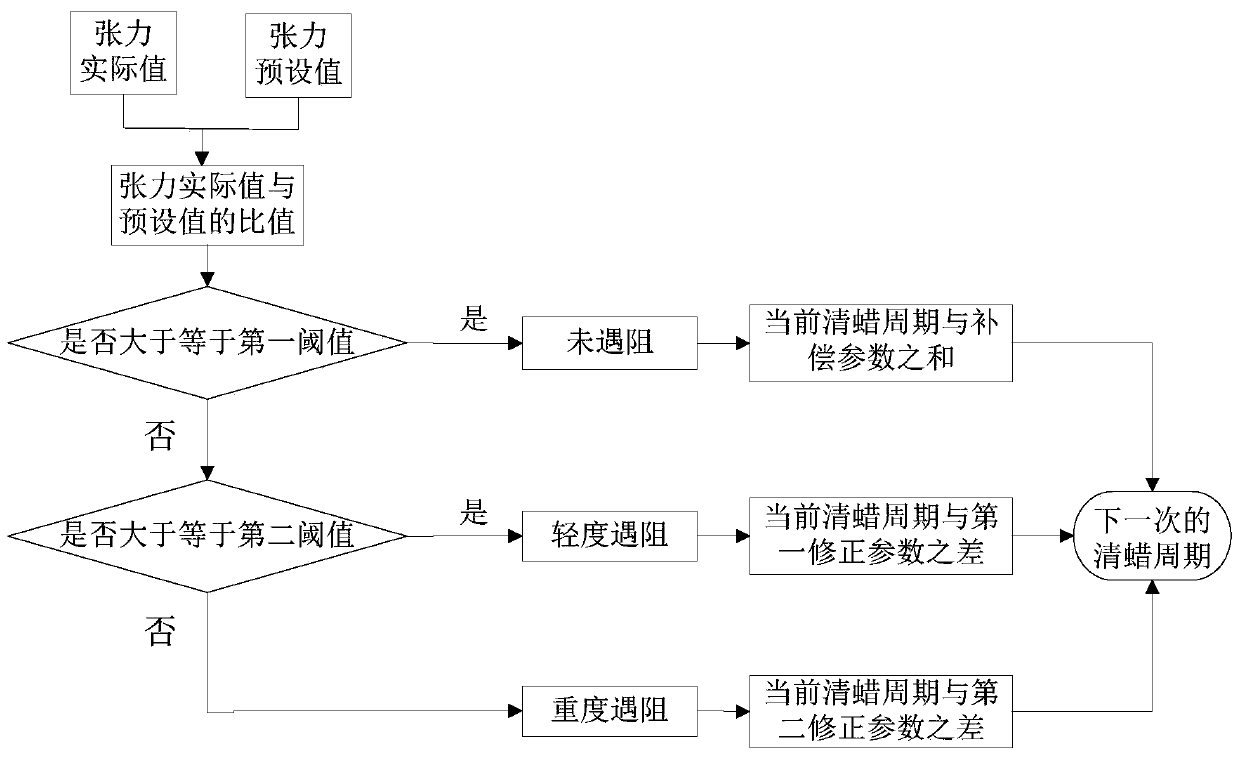

[0064] S2, according to the current wax removal process, the tension of the traction rope when the wax removal device is lowered to determine the level of resistance to wax removal;

[0065] S3. Determine the next waxing cycle according to the current waxing cycle and the level of resistance to waxing.

[0066] Exemplarily, obtaining the current wax removal period includes obtaining the current wax removal period stored in advance; or, obtaining the current wax removal period includes determining the difference between the current wax removal time and the last wax removal time, and the difference The value is used as the current wax removal cycle. The wax removal cycle is the time interval fro...

Embodiment 2

[0120] In this embodiment, the method for determining the wax removal period will be further described by taking the case where the depth of the wax precipitation point of an oil well exceeds 2 km as an example.

[0121] The most common wax removal depth in oil well wax removal is 2km, and when the wax removal cost is settled, the wax removal depth is 2km as a node, that is, when the wax removal depth is less than 2km, it is a kind of wax removal price. Wax costs will increase substantially. The general wax removal depth is 50-100m below the wax precipitation point. When the oil well depth is above 4km, due to the higher geothermal temperature, wax formation will not occur in the part exceeding the depth of 4km. Therefore, the wax removal with a depth of less than 2km can be called shallow wax removal; the wax removal with a depth of more than 2km is called deep wax removal. Because the oil well has a temperature gradient in the depth direction, the higher the oil well, the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com