Non-cured rubber asphalt waterproof coating and preparation method thereof

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the direction of asphalt coating, antifouling/underwater coating, coating, etc., and can solve the problems of smoke generation, poor creep performance, insufficient cohesive strength, etc. , to achieve the effect of good sealing, good cohesion and good secondary adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

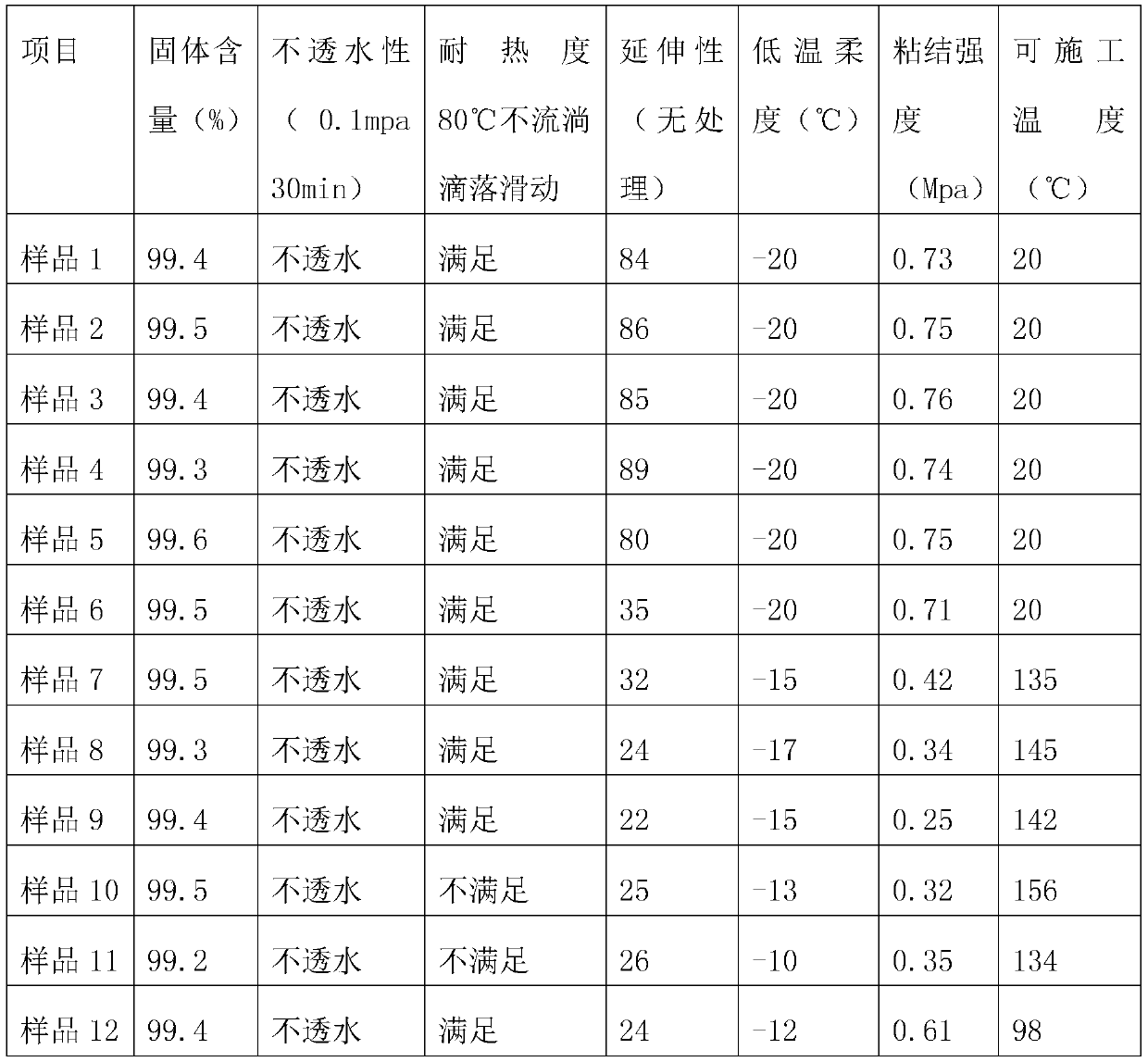

Examples

Embodiment 1

[0033] A non-curing rubber asphalt waterproof coating, which is mainly prepared by mixing the following raw materials according to weight percentage: 13.9% cationic styrene butadiene latex, 68% non-ionic emulsified asphalt, 17% octylphenol polyoxyethylene ether, ASE 60 alkali swelling Thickener 0.4%, polyurethane defoamer 0.4%, bactericide 0.1%, pH regulator 0.2%.

[0034] The present invention also provides a preparation method of non-curing rubber asphalt waterproof coating, including the following steps:

[0035] (1) Add cationic styrene butadiene latex and non-ionic emulsified asphalt into the dispersing machine, the speed of the dispersing machine is 250 rpm, the dispersion time is 40 minutes, and the dispersion is uniform to obtain mixture A;

[0036] (2) Add the polyurethane defoamer to the mixture A, the speed of the disperser is 250 rpm, and the dispersion is uniform to obtain the mixture B;

[0037] (3) Add surfactant to mixture B, increase the dispersion speed to 450 rpm, t...

Embodiment 2

[0042] A non-curable rubber asphalt waterproof coating, mainly prepared by mixing the following raw materials according to weight percentage: cationic styrene butadiene latex 18.3%, non-ionic emulsified asphalt 55%, nonylphenol polyoxyethylene ether 25%, ASE 60 alkali swelling Thickener 0.8%, polyurethane defoamer 0.3%, bactericide 0.2%, pH regulator 0.4%.

[0043] The present invention also provides a preparation method of non-curing rubber asphalt waterproof coating, including the following steps:

[0044] (1) Add cationic styrene-butadiene latex and non-ionic emulsified asphalt into the disperser at a speed of 300 rpm, a dispersion time of 30 minutes, and a uniform dispersion to obtain a mixture A;

[0045] (2) Add the polyurethane defoamer to the mixture A, the speed of the disperser is 300 rpm, the dispersion is uniform, and the mixture B is obtained;

[0046] (3) Add the surfactant to the mixture B, the speed of the dispersing machine is 500 rpm, the dispersion time is 50 minute...

Embodiment 3

[0051] A non-curable rubber asphalt waterproof coating, which is mainly prepared by mixing the following raw materials according to weight percentages: cationic styrene butadiene latex 15.2%, non-ionic emulsified asphalt 64.3%, carbon fatty alcohol polyoxyethylene ether 19.15%, ViscalexHV-30 alkali swelling Thickener 0.6%, polyurethane defoamer 0.3%, bactericide 0.15%, pH regulator 0.3%.

[0052] The present invention also provides a preparation method of non-curing rubber asphalt waterproof coating, including the following steps:

[0053] (1) Add cationic styrene-butadiene latex and non-ionic emulsified asphalt into the disperser at a speed of 300 rpm, a dispersion time of 30 minutes, and a uniform dispersion to obtain a mixture A;

[0054] (2) Add polyurethane defoamer to mixture A and disperse it evenly to obtain mixture B;

[0055] (3) Add the surfactant to the mixture B, the speed of the dispersing machine is 500 rpm, the dispersion time is 50 minutes, increase the dispersion spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com