Environment-friendly flame-retardant PLA plastic and preparation method thereof

An environmentally friendly, flame-retardant plastic technology, applied in the field of flame-retardant plastics, can solve the problems of harsh preparation conditions, low flame-retardant performance, toxic substances, etc., to ensure biocompatibility, excellent flame-retardant performance, good mechanical properties performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of environmentally friendly PLA fire-retardant plastics, its preparation method comprises the steps:

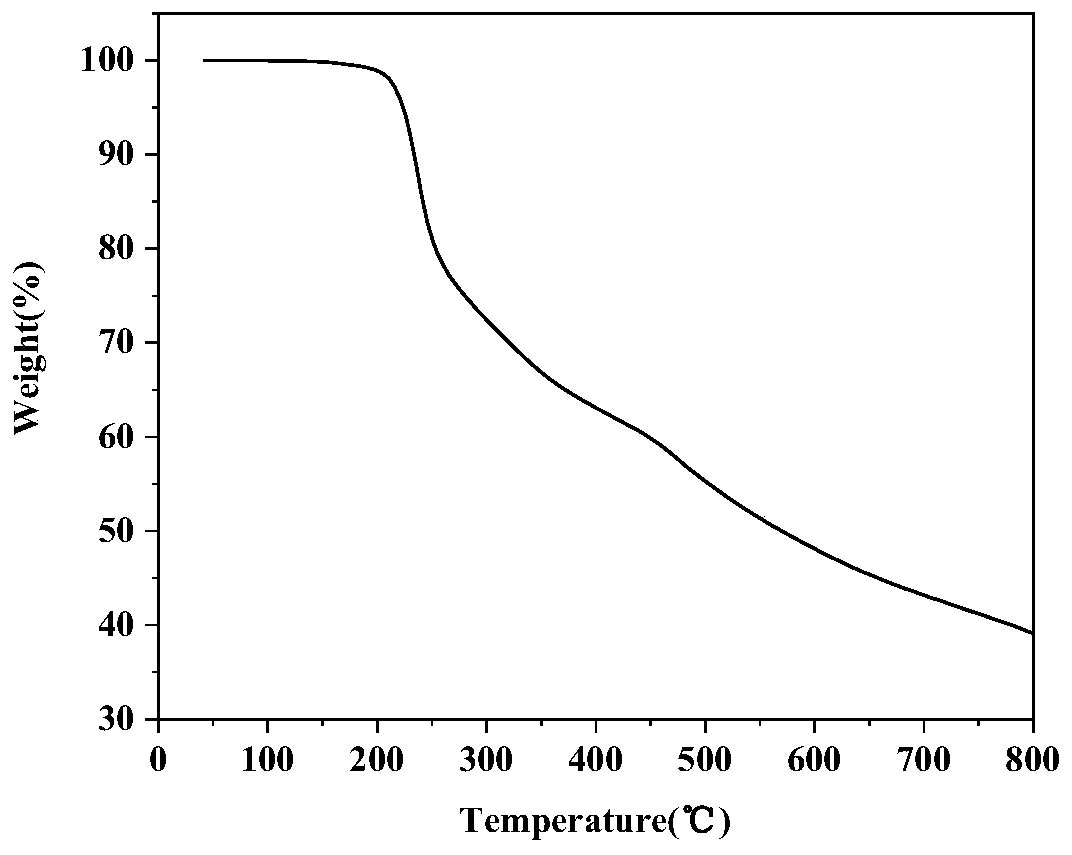

[0037] 1) Dissolve 0.72 parts of phytic acid in 50 parts of water, add 4.28 parts of furfurylamine, stir and react for 30 minutes under nitrogen atmosphere and room temperature, remove water by rotary evaporation, and dry at 60°C for 6 hours to obtain a composite environmentally friendly flame retardant;

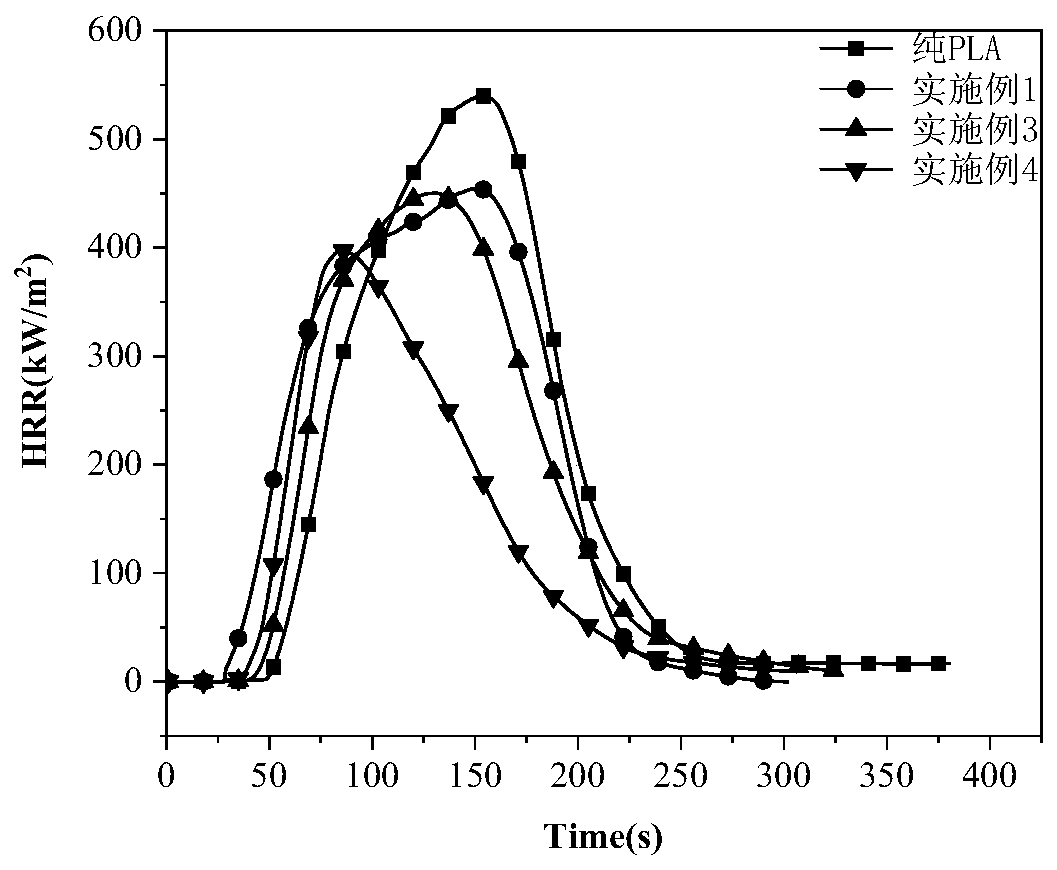

[0038] 2) Put 5 parts of the obtained composite environmentally friendly flame retardant and 95 parts of PLA into the torque rheometer, the mixing temperature is 180 ° C, and the mixing speed is gradually increased from 10 rpm to 100 rpm in increments of 15 rpm; The mixing time of each section is 30s. After the speed is increased to 100rpm, continue mixing for 10 minutes to obtain compound 1; send compound 1 into the screw extruder, and extrude the compound at 185°C and 10Mpa. The material is shredded to obtain the environmentally friendly flame-retardant PLA ...

Embodiment 2

[0041] A kind of environmentally friendly PLA fire-retardant plastics, its preparation method comprises the steps:

[0042] 1) Dissolve 1.25 parts of phytic acid in 50 parts of water, add 6.25 parts of furfurylamine, stir and react for 30 minutes under nitrogen atmosphere and room temperature, remove water by rotary evaporation, and dry at 60°C for 6 hours to obtain a composite environmentally friendly flame retardant;

[0043] 2) Put 7.5 parts of the obtained composite environmentally friendly flame retardant and 92.5 parts of PLA into the torque rheometer, the mixing temperature is 180 ° C, and the mixing speed is gradually increased from 10 rpm to 100 rpm in increments of 15 rpm; The mixing time of each section is 30s. After the speed is increased to 100rpm, continue mixing for 10 minutes to obtain compound 1; send compound 1 into the screw extruder, and extrude the compound at 185°C and 10Mpa. The material is shredded to obtain the environmentally friendly flame-retardant ...

Embodiment 3

[0045] A kind of environmentally friendly PLA fire-retardant plastics, its preparation method comprises the steps:

[0046] 1) Dissolve 1.43 parts of phytic acid in 50 parts of water, add 8.57 parts of furfurylamine, stir and react for 30 minutes under nitrogen atmosphere and room temperature, remove water by rotary evaporation, and dry at 60°C for 6 hours to obtain a composite environmentally friendly flame retardant;

[0047] 2) Put 10 parts of the obtained composite environmentally friendly flame retardant and 90 parts of PLA into the torque rheometer, the mixing temperature is 180 ° C, and the mixing speed is gradually increased from 10 rpm to 100 rpm in increments of 15 rpm; The mixing time of each section is 30s. After the speed is increased to 100rpm, continue mixing for 10 minutes to obtain compound 1; send compound 1 into the screw extruder, and extrude the compound at 185°C and 10Mpa. The material is shredded to obtain the environmentally friendly flame-retardant PLA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com