Preparation method of sulfur-phosphorus-nitrogen type extreme-pressure anti-wear agent

An extreme pressure anti-wear agent, sulfur phosphorus nitrogen technology, applied in the field of anti-wear agents, can solve problems such as poor copper sheet corrosion, system copper sheet corrosion, and equipment corrosion, and achieve environmental protection, corrosion reduction, and stable synthesis methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

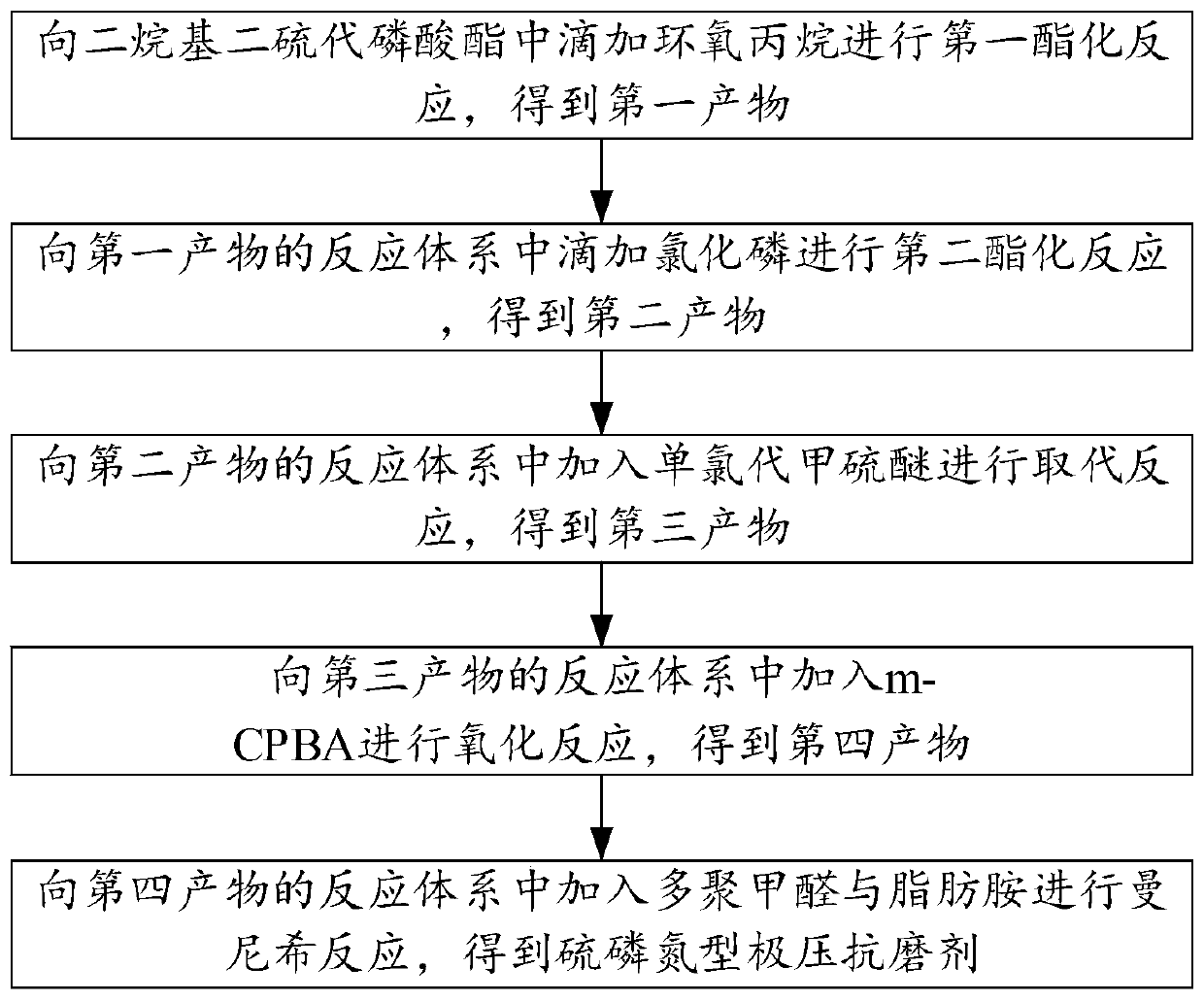

[0040] Such as figure 1 As shown, the present invention provides a preparation method of sulfur phosphorus nitrogen type extreme pressure antiwear agent, comprising:

[0041] Step 1, adding propylene oxide dropwise to the dialkyl phosphorodithioate to carry out the first esterification reaction to obtain the first product; wherein,

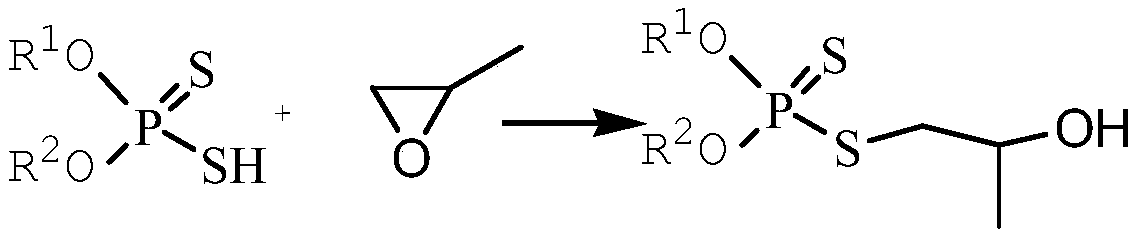

[0042] The first esterification reaction is:

[0043]

[0044] In the formula, R 1 with R 2 for C 4 ~C 12 Alkyl group; the reaction temperature of the first esterification reaction is 70-85°C, and the reaction time is 1-2h; the acid value of the system is detected during the reaction process, and the second esterification reaction can be carried out when the acid value is not greater than 10KOHmg / g.

[0045] The specific steps are:

[0046] Add 0.32mol of dialkyl phosphorodithioate into a four-necked flask equipped with a thermometer, a reflux condenser, a dropping funnel and a stirrer, and slowly add 0.33mol of propylene oxide dropwise t...

Embodiment 1

[0076] The invention provides a preparation method of sulfur phosphorus nitrogen type extreme pressure antiwear agent, comprising:

[0077] Step 1, the first esterification reaction: add O-n-butyl-O'-2-ethylhexyl dialkyldithio Phosphate ester 0.32mol, slowly add 0.33mol propylene oxide dropwise to the reaction system under the condition of stirring, control the temperature of the system not to exceed 30°C during the dropwise addition process, the appropriate time for the dropwise addition is 45min, and raise the temperature to 75°C after the dropwise addition is completed ℃, heat preservation reaction for 1-2h, and detect the acid value of the system during the process. When the acid value is not greater than 10KOHmg / g, the next step reaction can be carried out.

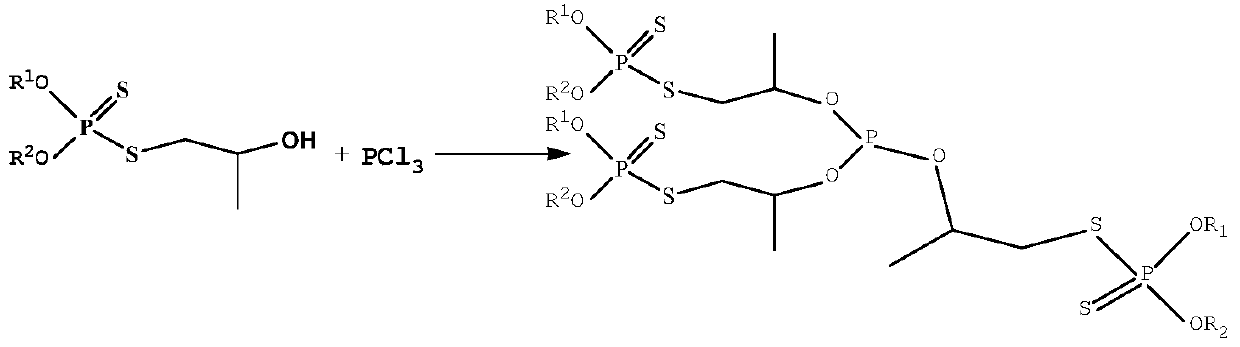

[0078] Step 2, the second esterification reaction: Slowly add PCl dropwise to the above reaction system through the dropping funnel 3 , the dropping time is preferably 45min. During the dropping process, the reactio...

Embodiment 2

[0083] The invention provides a preparation method of sulfur phosphorus nitrogen type extreme pressure antiwear agent, comprising:

[0084] Replacing O-n-butyl-O'-2-ethylhexyl dialkyl phosphorodithioate with O-sec-butyl-O'-2-ethylhexyl dialkyl phosphorodithioate, other operations Consistent with the description in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com