Stretch film automatic packaging machine for raised folds shrunk by preheating based on stretch-resisting winding

An automatic packaging machine and stretch film technology, applied in the direction of pre-stretching mechanism, packaging, transportation packaging, etc., can solve the problems of lower product preservation quality, uneven packaging of side lengths, interference with side sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

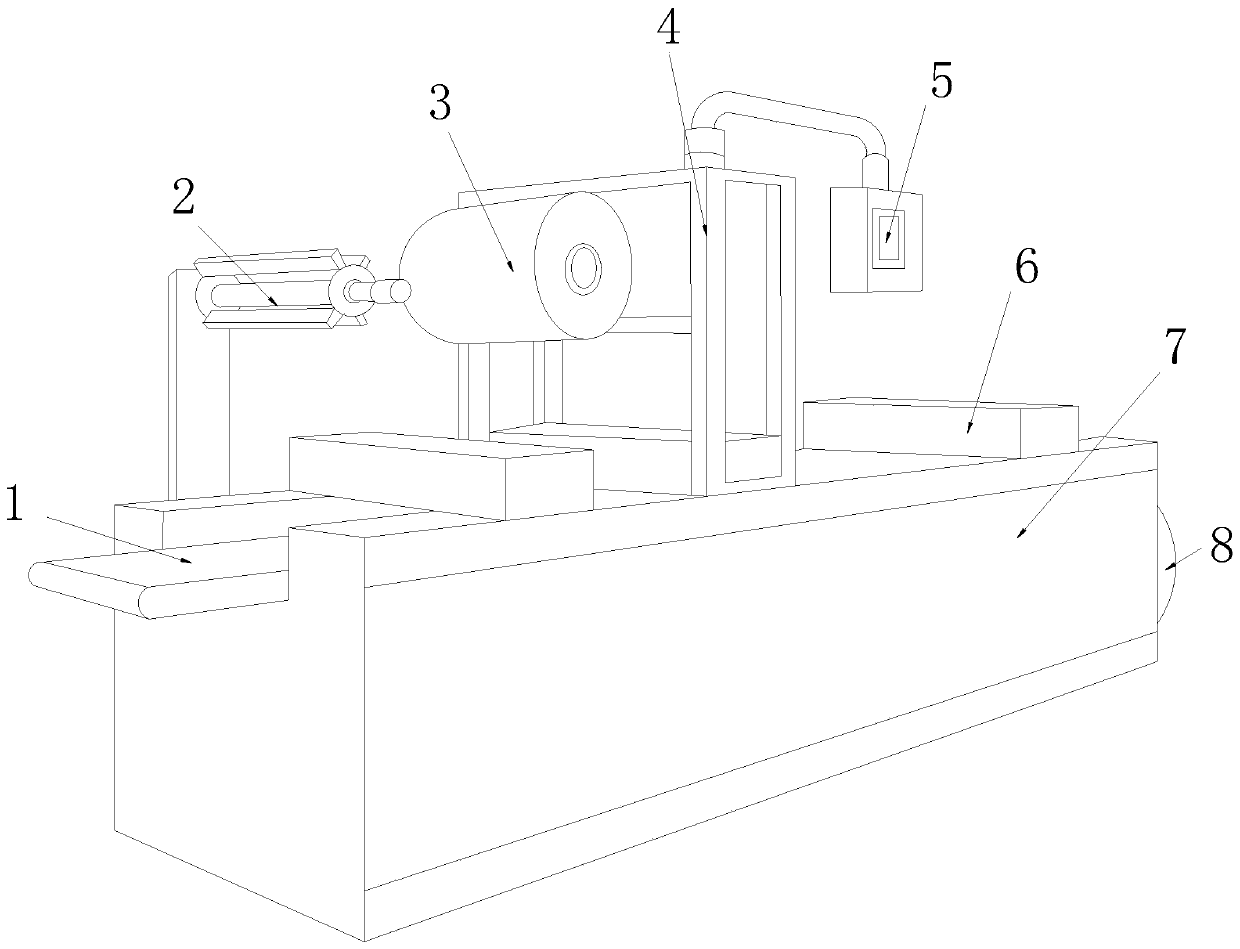

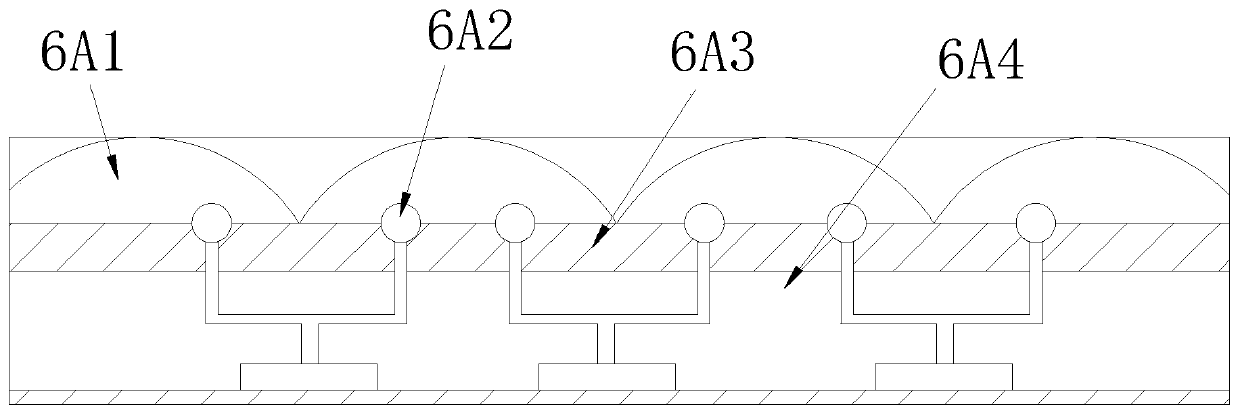

[0032] see Figure 1-Figure 6, the present invention provides an automatic stretch film packaging machine based on drag-and-twist preheating shrinkage and pleating, its structure includes: conveyor belt 1, film wrapping roller frame 2, film tape cylinder 3, vertical rod frame 4, man-machine The interface 5, the heat-shrinkable lifting base 6, the packaging box groove 7, and the stretching roller 8, the heat-shrinkable lifting base 6 and the packaging box groove 7 adopt clearance fit and are on the same vertical plane, and the pulling The stretching roller 8 is nested on the right side of the packaging box groove 7, and the film belt cylinder 3 and the human-machine interface 5 are respectively installed on the left and right sides of the pole frame 4, and the pole frame 4 is inserted into the packaging box. On the top of the middle section of the casing groove 7 and perpendicular to each other, the conveyor belt 1 and the film wrapping roller frame 2 are arranged on the upper ...

Embodiment 2

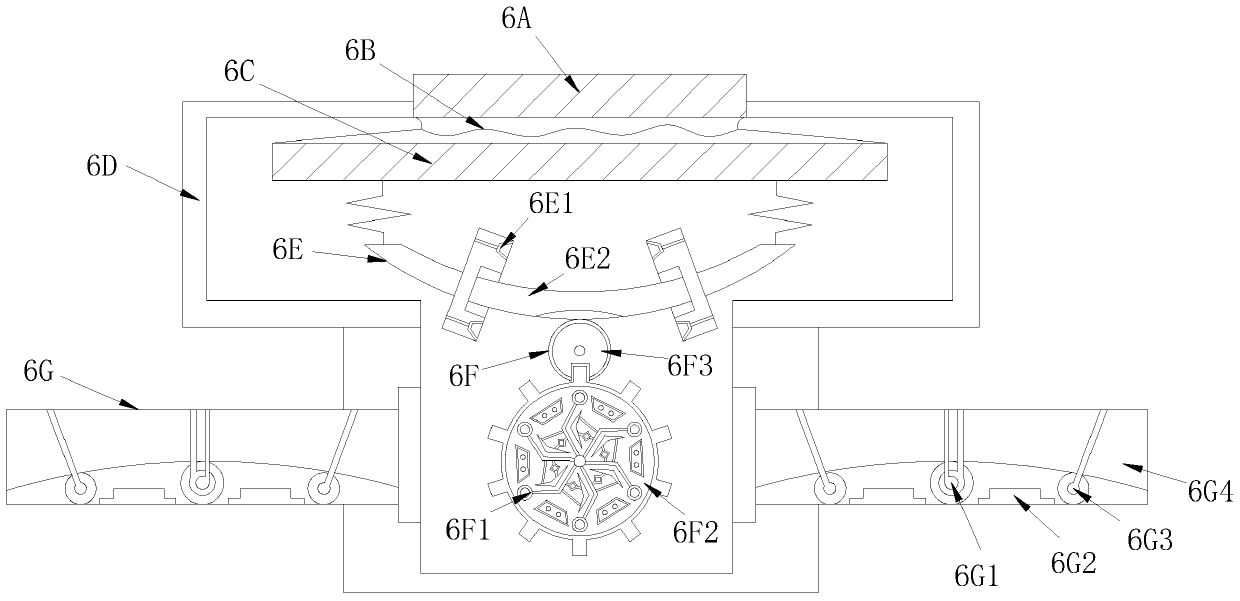

[0039] see Figure 1-Figure 6 , the present invention provides a stretch film automatic packaging machine based on dragging and winding preheating, shrinking and folding. Other aspects are the same as in Embodiment 1, except that:

[0040] see figure 2 , the carriage wing plate 6G is composed of double lug buckle wheel 6G1, liner sliding piece 6G2, roller 6G3, and arc top groove plate 6G4, and the liner sliding piece 6G2 and roller 6G3 are installed in the arc top groove The inside of the plate 6G4 is on the same horizontal plane, the double lug buckle 6G1 is movably connected with the arc-top groove plate 6G4 and is perpendicular to each other, and a superposition of sliding surface friction and rolling friction is formed by the liner slide 6G2 and the roller 6G3 Balance the movement effect and ensure the overall stretch film surface coverage effect.

[0041] see Image 6 , the double lug buckle wheel 6G1 is composed of a thick lug bar 6G11, a thin lug bar 6G12, a thick r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com