Numerical control torque synchronous hydraulic bender slide block flexivity compensation mechanism

A slider deflection and compensation mechanism technology, which is applied in the field of hydraulic bending machines, can solve problems such as unsatisfactory bending effects, and achieve the effects of low manufacturing cost and excellent repeat positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

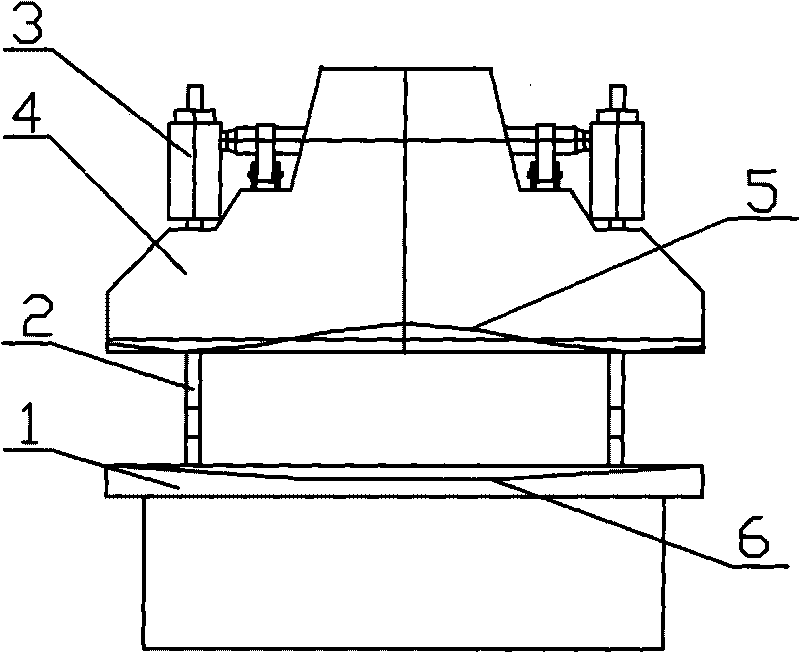

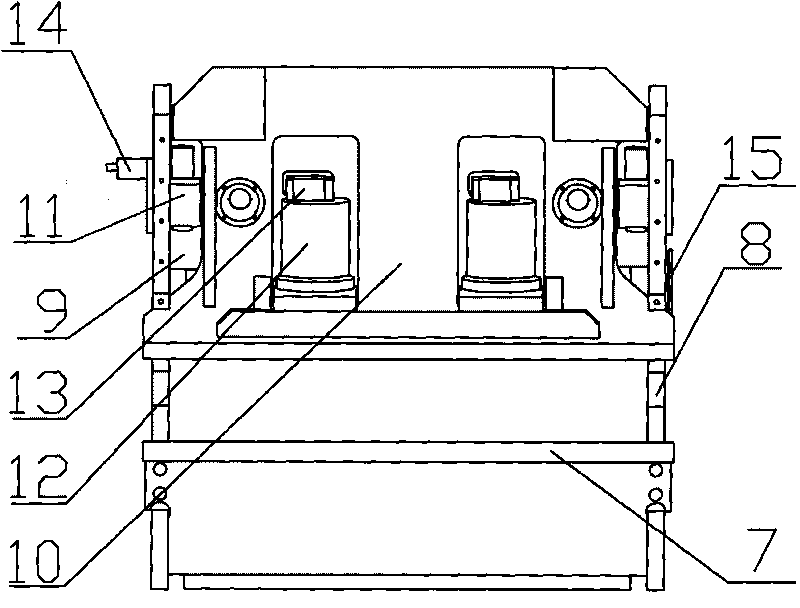

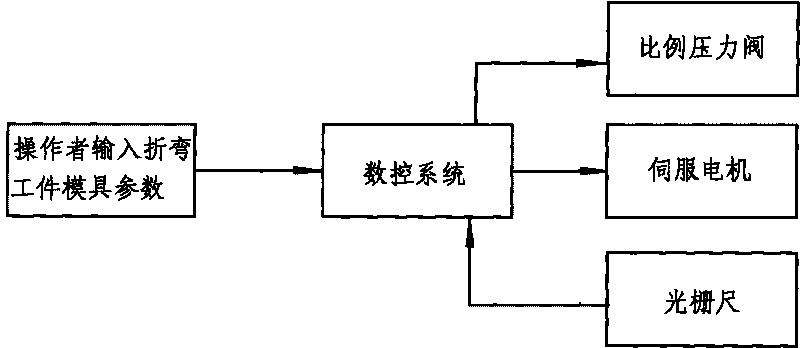

[0012] attached by figure 2 , attached image 3 It can be seen that the slider deflection compensation mechanism of the CNC torsion axis synchronous hydraulic bending machine includes a workbench 7, left and right wall panels 8, front and rear beams 9, sliders 10, left and right stopper seats 11, and left and right oil cylinders 12. The left and right wall panels 8 are located on The side of the bending machine is fastened on the workbench 7. The slider 10 is set in the middle of the front and rear beams 9. The piston rods of the left and right oil cylinders 12 are connected with the slider 10. Two square holes are set on the slider 10. The left and right oil cylinders 12 Place in the square hole and be fixed on the front and rear beams 9. When working, the up and down movement of the slider is driven by the oil cylinder, and the slider works synchronously through the synchronous swing arm. Finally, the slider reaches the bottom dead center, and the slider is pressed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com