Workpiece pressing device for broaching machine

A technology for pressing devices and workpieces, which is applied in the direction of broaching devices, clamping devices, broaching machines, etc., which can solve problems such as potential safety hazards, workpiece tipping, and inability to ensure uniform pressure on workpieces, so as to improve safety and workpiece pressure. Firm and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

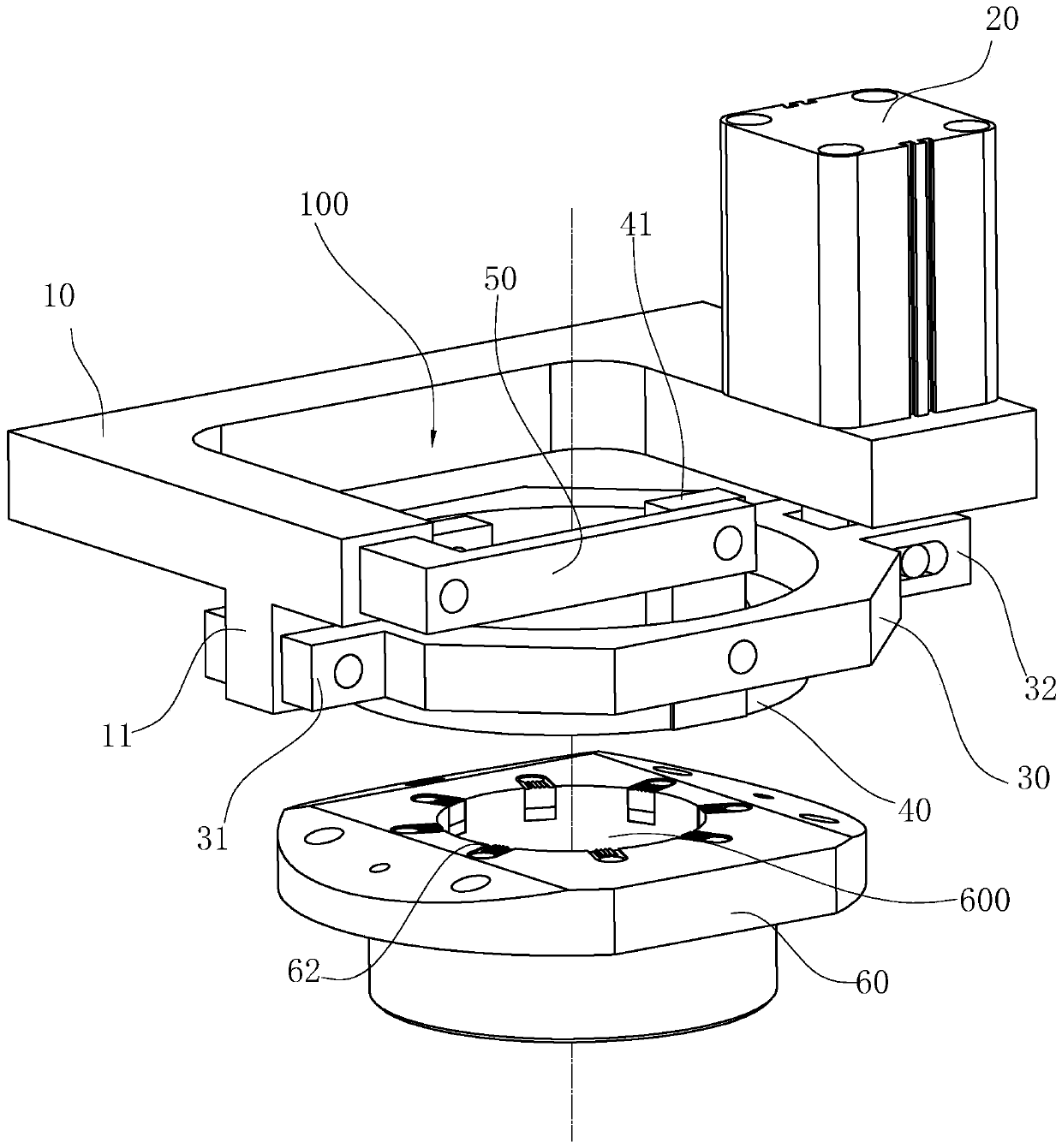

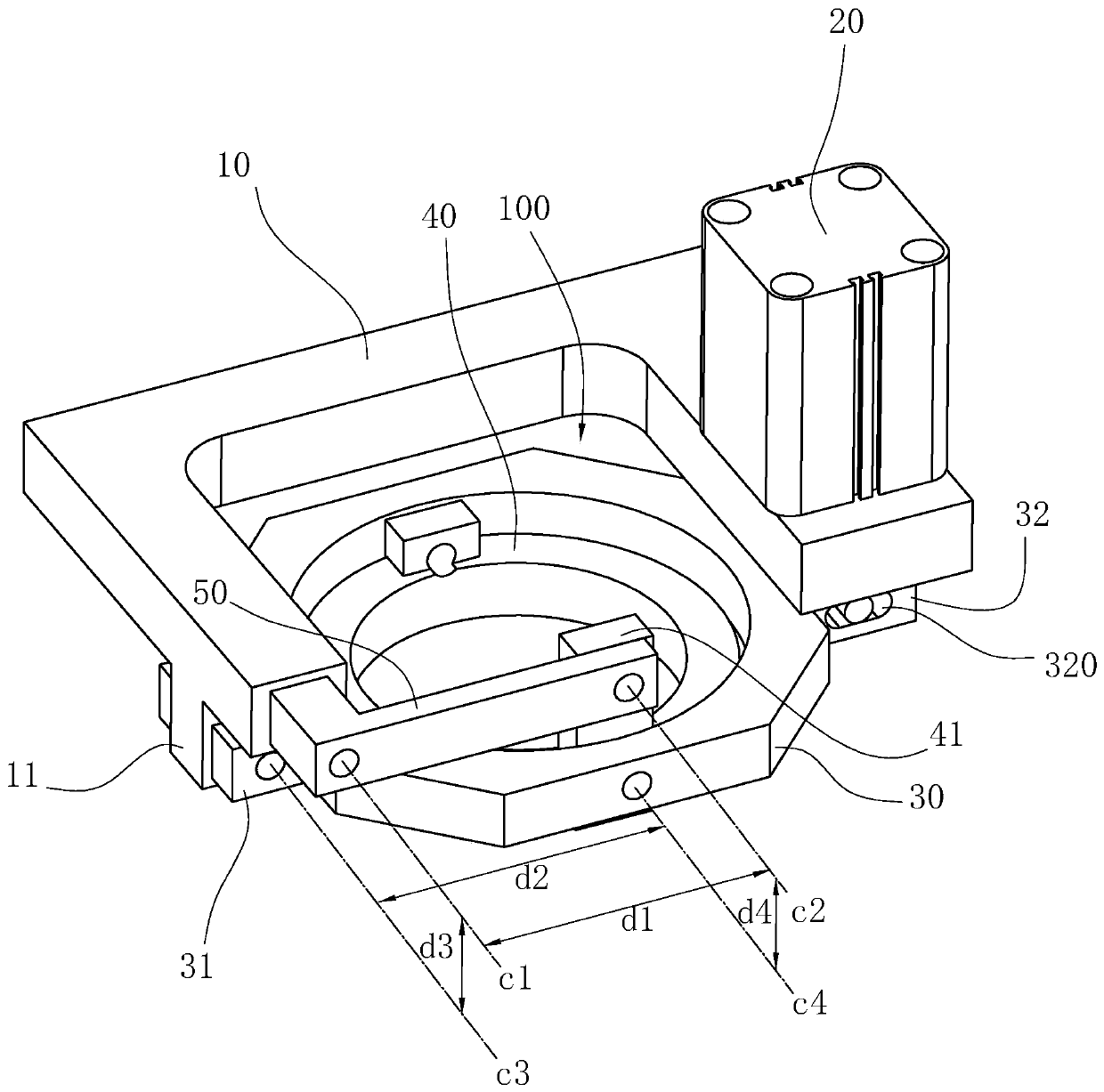

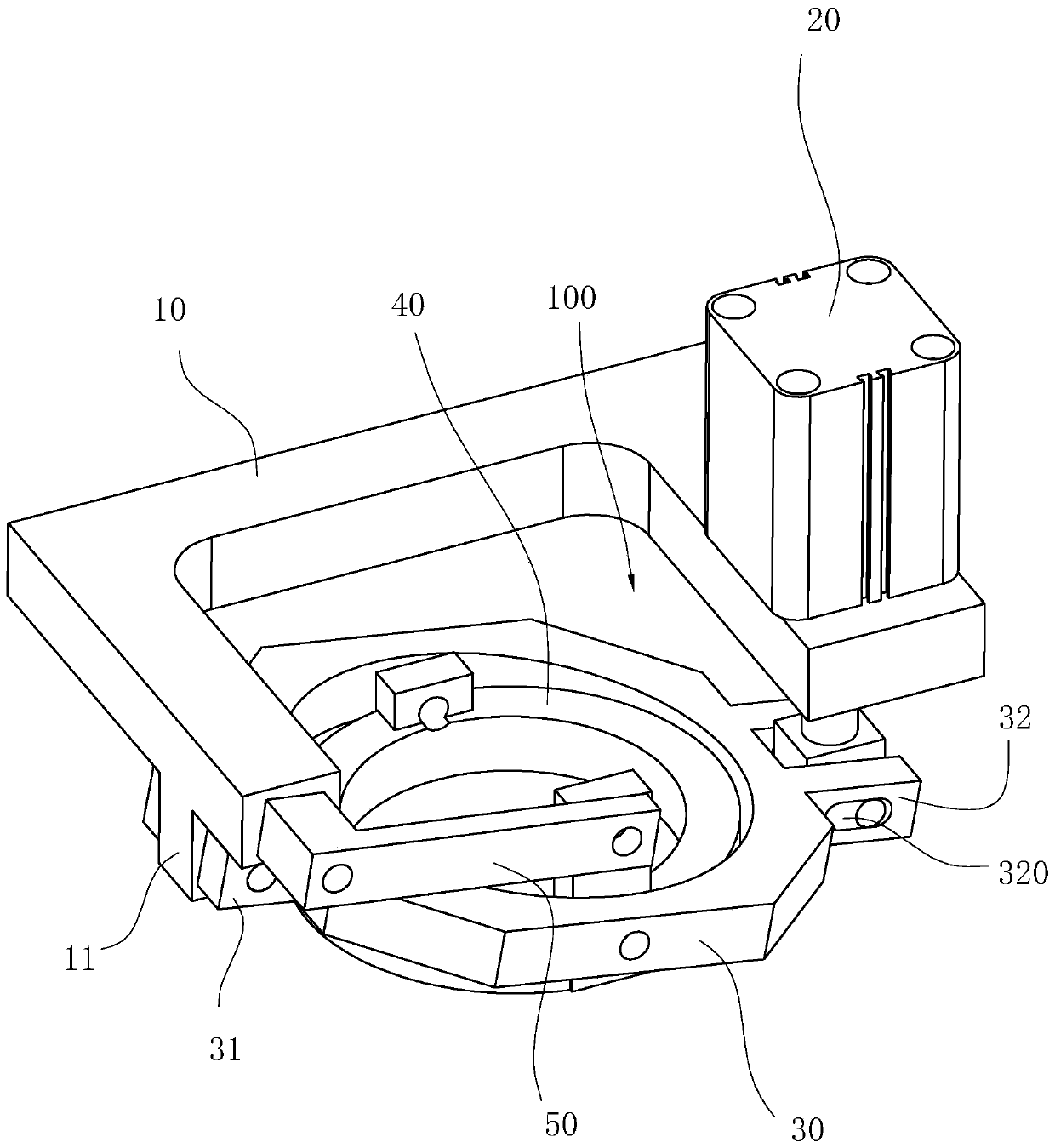

[0032] see Figure 1-Figure 7 , a workpiece pressing device for a broaching machine includes a support frame 10 , a driving device 20 , a connecting sleeve 30 , a pressure ring 40 , at least one rocker arm 50 and a positioning faceplate 60 .

[0033] see Figure 1-Figure 3 , the support frame 10 is fixed relative to the workbench (not shown), specifically located above the workbench. There is a relief space 100 on the support frame 10, specifically, the relief space 100 of the support frame 10 is located above the workpiece placement position of the workbench (taking the internal tooth groove of a ring-shaped workpiece as an example, the workpiece placement position is a central hole structure) , for the broach to pass through. The driving device 20 of this embodiment can be arranged on the support frame 10, specifically, the driving device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com