Rolling bearing arrangement

A bearing device and rolling bearing technology, applied in the field of bearing devices, can solve problems such as wear and tear, and achieve the effect of small unit area pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

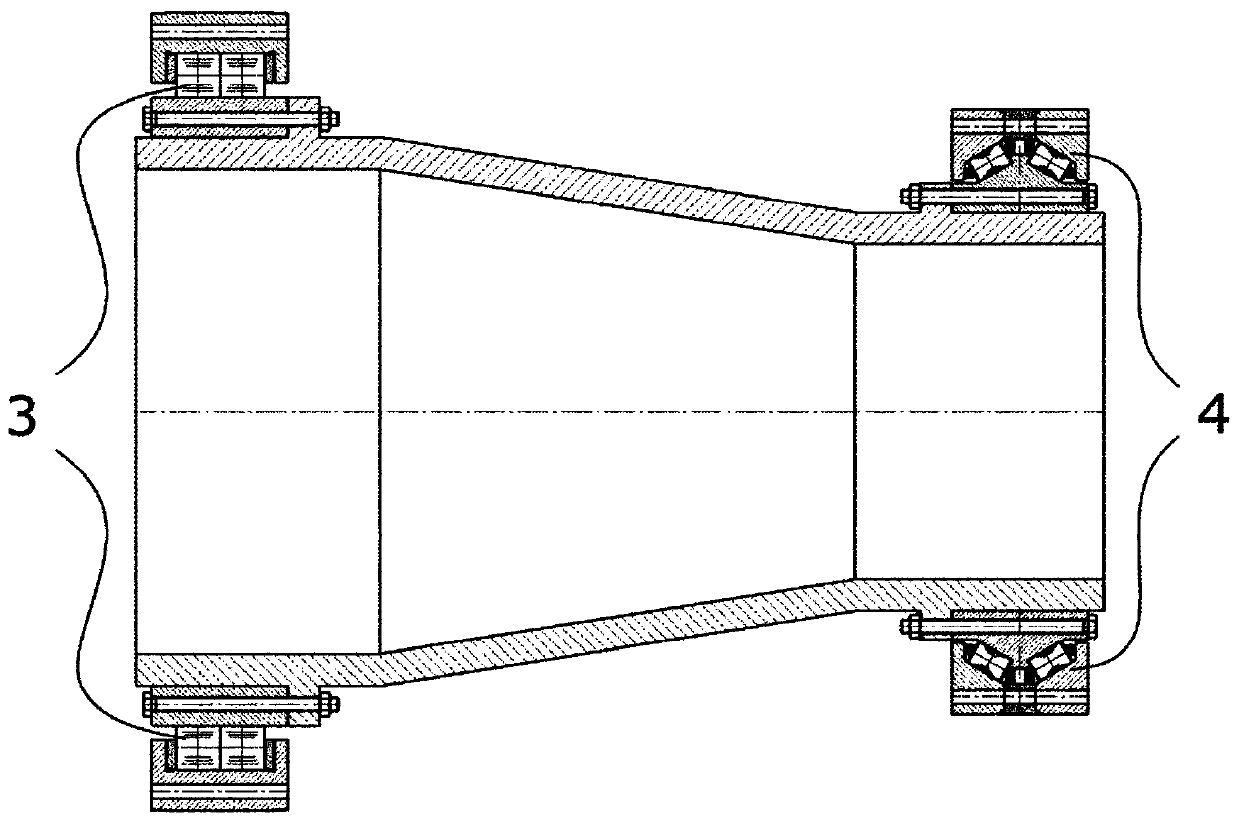

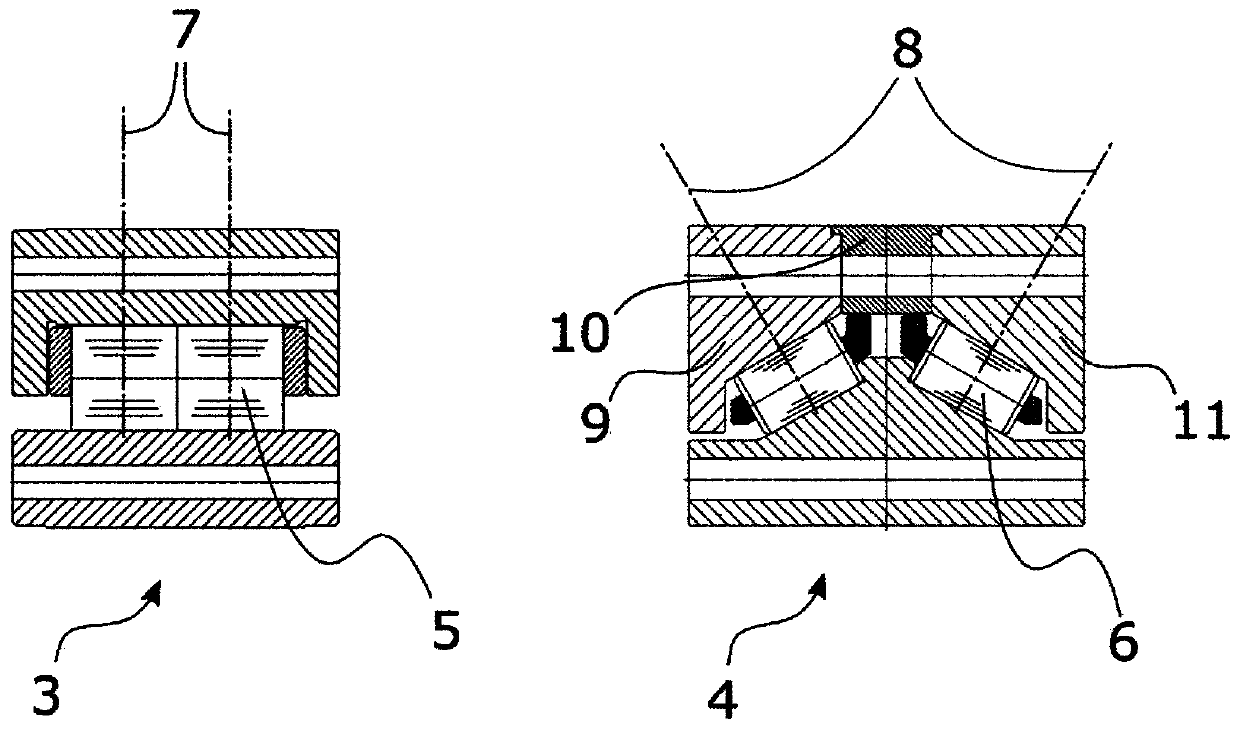

[0025] figure 1 is a schematic radial cross-sectional view of a bearing arrangement of a rotor shaft of a wind power plant according to a possible embodiment of the present invention. In wind power plants, the hub is connected to the generator via the rotor shaft, whereby the rotation of the hub is transmitted to the generator and converted there into electrical energy. Here, according to the invention, the shaft is rotatably mounted by means of two rolling bearing arrangements 3 and 4 . Depending on their position relative to the hub and generator, the two rolling bearing arrangements 3 and 4 are referred to as hub-side bearing 3 and generator-side bearing 4 . The hub side corresponds to the left side in the figure, and the generator side corresponds to the right side.

[0026] In this embodiment, the hub-side bearing 3 is formed by two rows of cylindrical rollers 5 which roll between two bearing rings in rotation. The cylindrical rolling bodies transmit the forces between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com