Small-scale equipment part detection method based on weak supervision collaborative learning in open scene of electric power field

A technology of equipment components and detection methods, applied in the field of smart grid, can solve the problems of decreased detection speed, slow detection speed, low efficiency, etc., to achieve the effect of improving speed and accuracy, and enhancing learning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] A small-scale equipment component detection method based on weakly supervised collaborative learning in an open scene in the electric power field, including the following steps:

[0071] S1: Preprocessing the images in the power open scene: use the annotation tool to annotate the normalized graphics;

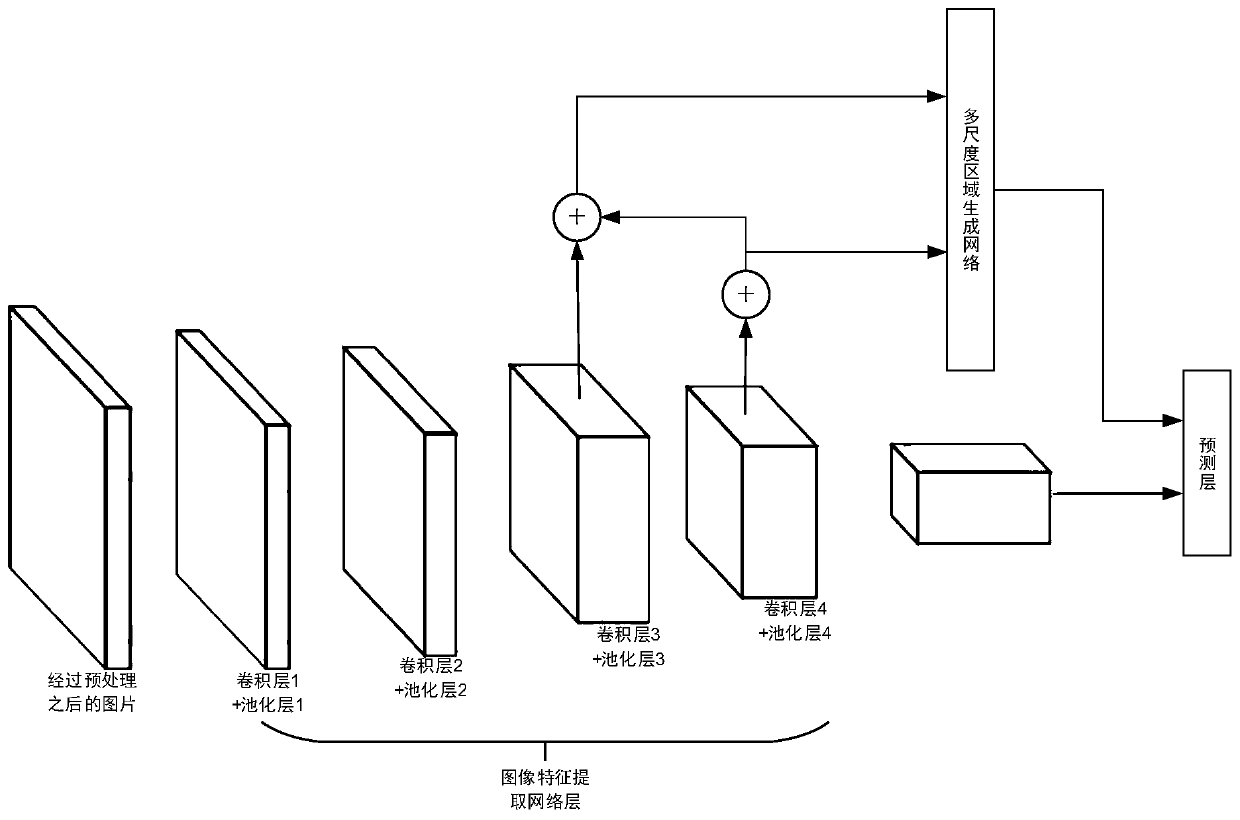

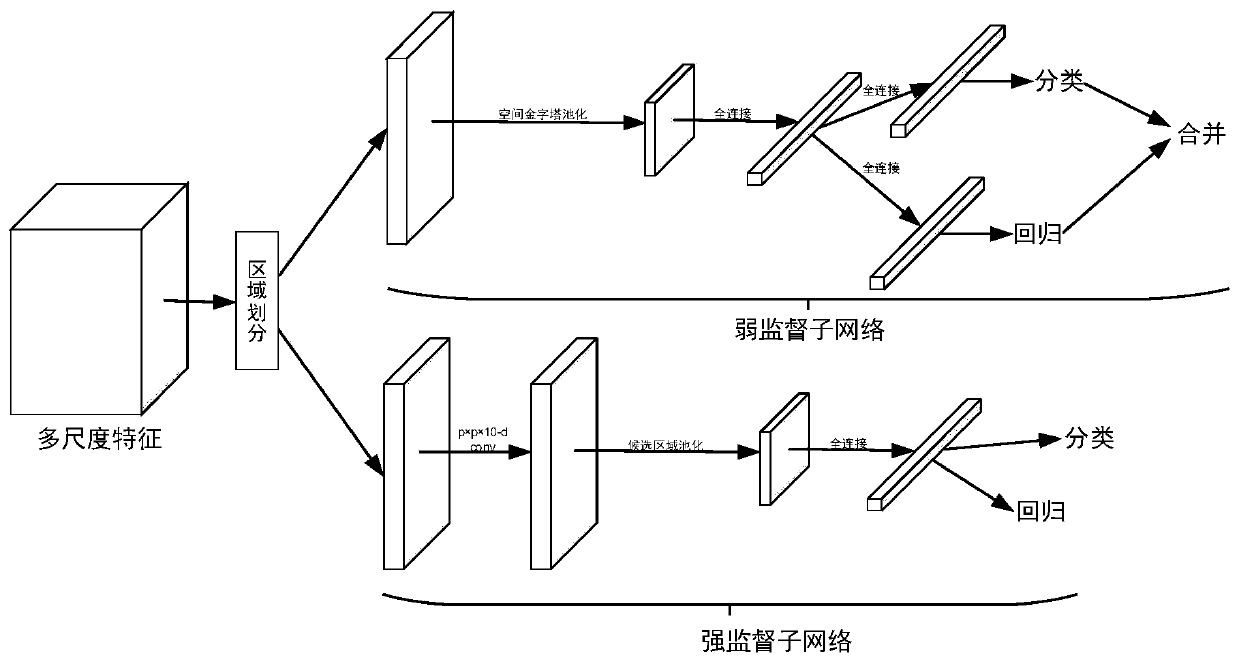

[0072] S2: Extract image information and feature fusion: extract feature maps containing different scales of pictures, use ResNet's conv1-conv4 convolutional layer for feature extraction, and construct a feature pyramid between conv3 and conv4 convolutional layers after obtaining features; The purpose of inventing and constructing a feature pyramid is to enrich the extracted feature information, and at the same time increase the feature extraction time. Therefore, the research experiment found that when only the pyramid is constructed between the conv3 and conv4 convolutional layers, the richness of feature information and the extraction speed can be achieved. Trade-off; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com