High-pressure hydrogen fatigue test environmental chamber for workpieces

A high-pressure hydrogen and fatigue testing technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., to achieve the effect of simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

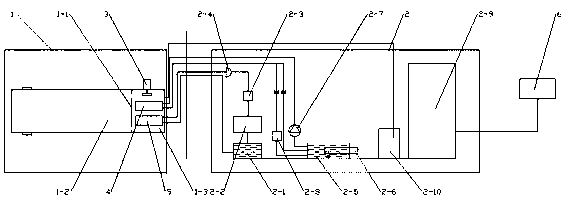

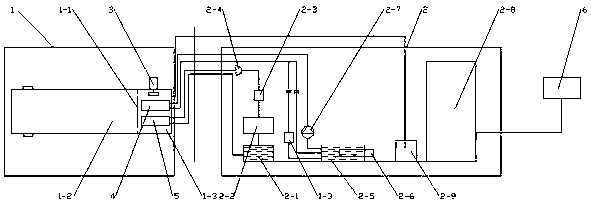

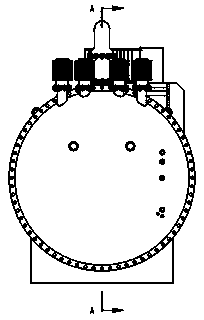

[0032] An environmental chamber for high-pressure hydrogen fatigue testing of key parts, which includes an environmental chamber 1 and a host 2, the environmental chamber 1 is located in an explosion-proof area, and the host 2 is located in a non-explosion-proof area; the environmental chamber 1 is vertically A partition 1-1 is provided, and the partition 1-1 is fixedly connected with the environmental cabin 1, and the interior of the environmental cabin 1 is divided into an environmental chamber 1-2 and a temperature control room 1-3, and the upper part of the partition 1-1 is provided with The circulating air outlet is provided with a circulating air inlet at the lower part, and the environmental chamber 1-2 and the temperature control room 1-3 are respectively connected through the circulating air outlet and the circulating air inlet to form a circulating air duct. The temperature control room 1-3 is composed of A forced circulation device 3, a heat exchanger 4, and an evapo...

Embodiment 2

[0053] A hydrogen storage bottle high-pressure hydrogen fatigue test environment cabin, on the basis of embodiment 1, further said host 2 also includes a humidifier 2-10, and the humidifier 2-10 is connected to the environment cabin body 1 through a pipeline to form a humidification system, The environmental cabin 1 is also provided with a water vapor outlet, which communicates with the temperature control room and is located below the forced circulation device 3; the evaporator is equipped with a number of dehumidification pipes to form a dehumidification system. A water receiving tray is also installed in the temperature control room, and the water receiving tray is located below the evaporator; preferably, the humidifier 2-10 is an external stainless steel boiler humidifier; the host 2 also includes an operating system 2-9, the A temperature sensor and a humidity control sensor are also installed in front of the air outlet. The operating system 2-9 controls and connects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com