Rotary agricultural and forestry waste continuous pyrolysis device with heat energy self-supply function

An agricultural and forestry waste, rotary technology, applied in the direction of biofuels, special forms of dry distillation, indirect heating dry distillation, etc., can solve the problems of undiscovered patent documents, uneven pyrolysis of materials, and large space occupation. Processing equipment, efficient continuous production, and the effect of reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

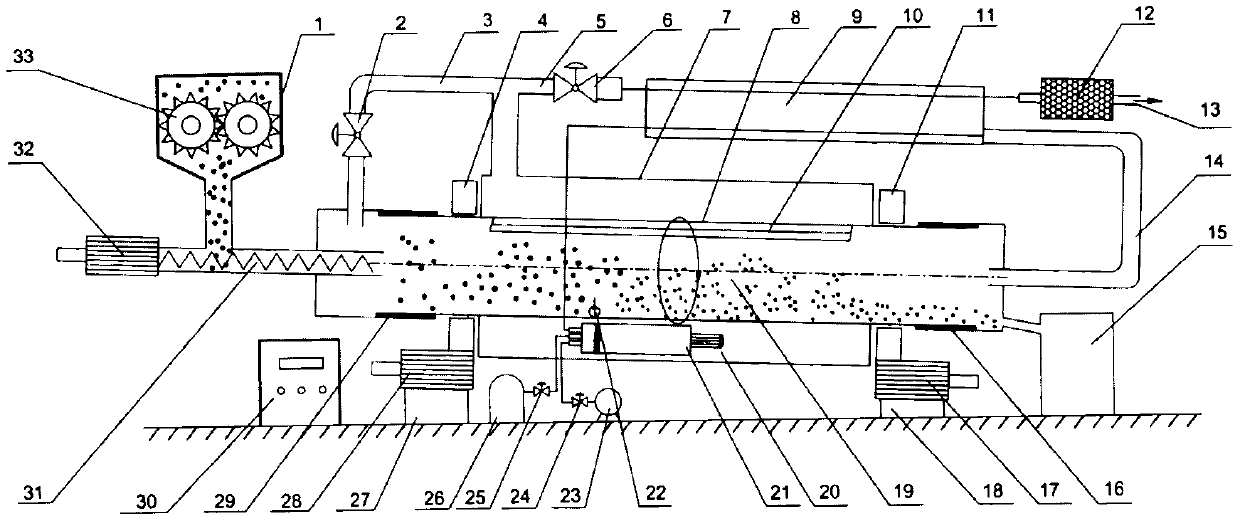

[0033] A rotary continuous pyrolysis device for agricultural and forestry waste with self-supply of heat energy. Its innovation is that it includes a feeding device 1, a crushing gear 33 is installed on the feeding device, and a screw feeder 31 is installed under the crushing gear. There is a pyrolysis drum 8 in the pyrolysis reaction chamber 19, and a scraper 10 is arranged on the pyrolysis drum 8. The two ends of the pyrolysis drum are respectively connected with the jacket 16, 29 through a seal, and the two ends of the pyrolysis drum are also sleeved with ring gears 4, 11. A gear used in conjunction with the ring gear is provided under the ring gear. The rotating shaft of the gear is connected to the gear motors 17 and 28 to rotate the pyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com