Papermaking wastewater pretreatment process adopting chemical dosing type CSTR and coagulation air floatation

A technology of papermaking wastewater and coagulation air flotation, which is applied in the direction of processing wastewater treatment, flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Coagulation and sedimentation process effect, incomplete separation of pollutants and other problems, to achieve the effect of reducing inhibition and poisoning, improving effect, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

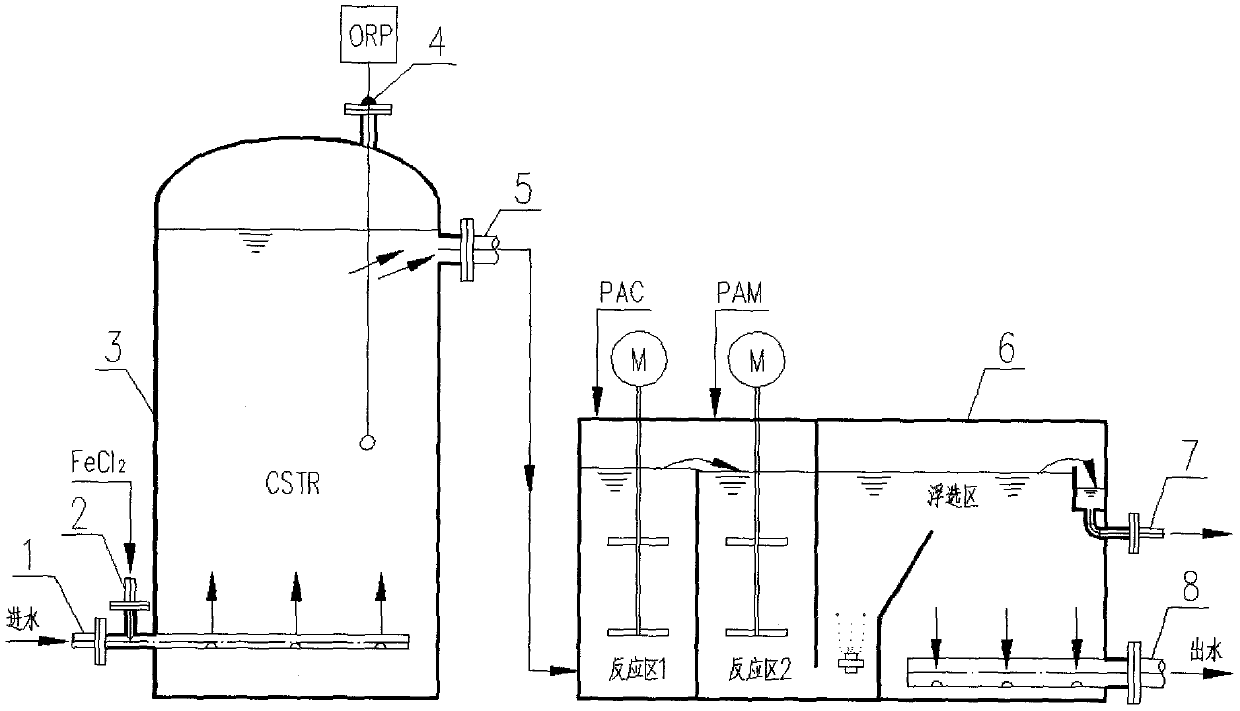

Method used

Image

Examples

Embodiment 1

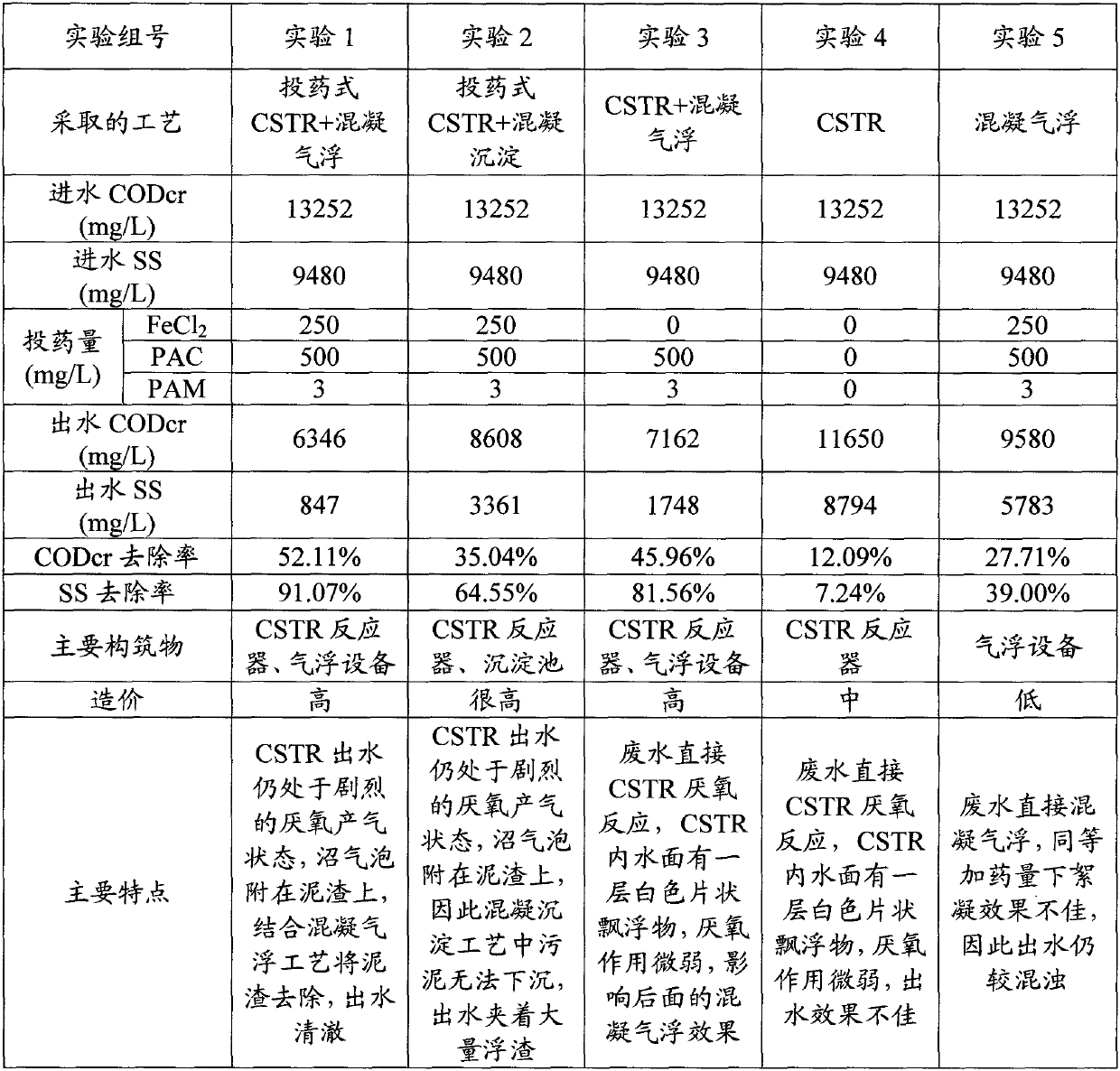

[0034] In order to more accurately explore the characteristics of the combined process of "dosing CSTR + coagulation air flotation", the present invention simulates the operating conditions of the actual project, taking "dosing CSTR + coagulation air flotation" as experiment 1, and at the same time made a control experiment around experiment 1 2 to 5, the main steps of the experiment are as follows:

[0035] Step 1: In the experimental CSTR small test equipment (effective volume 1m 3 ) into the mud-water mixture discharged from a firecracker paper papermaking wastewater CSTR.

[0036] Step 2: In the CSTR small test equipment of experiment 1, experiment 2, experiment 3 and experiment 4, use 0.5m 3 Inject a certain firecracker paper papermaking wastewater at a speed of / h, and at the same time, Fecl was added to the wastewater at a concentration of 250mg / L in Experiment 1 and Experiment 2 2 solution.

[0037] Step 3: The CSTR effluent from Experiment 1 and Experiment 3 flowed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com