A kind of preparation method of graphene hydrogen-rich ceramic ball

A graphene, ceramic ball technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of heavy metal production, high economic cost, increase, etc., and achieve nutritional mineral content. Increase and decrease ORP value, the effect of high hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

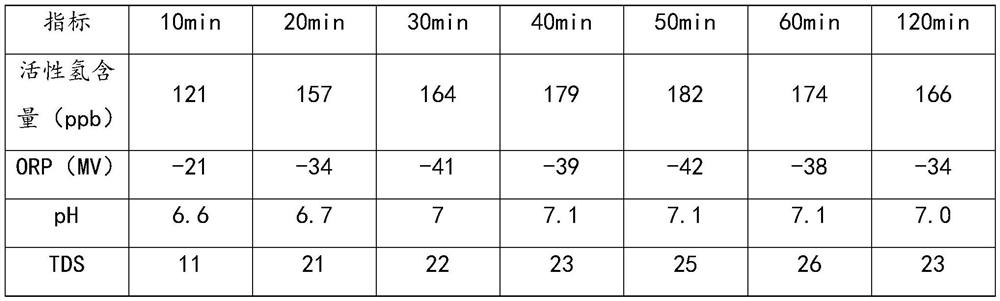

Embodiment 1

[0029] A preparation method of graphene hydrogen-rich ceramic balls, comprising the following steps:

[0030] (1) In parts by weight, take 3 parts of platinum, 4 parts of iron, 3 parts of zinc, 4 parts of magnesium, 3 parts of silicon, mix with 1 part of graphene and 12 parts of alcohol, grind into a slurry in a pressure tank, The pressure in the pressure tank is 500kpa;

[0031] (2) Spray and granulate the slurry of step (1) in a spray granulation tower to make micron-scale micro-battery material;

[0032] (3) Add deionized water to the product of step (2) for molding treatment. The amount of deionized water can be flexibly increased or decreased here, generally adding 10 parts by weight to ensure better molding;

[0033] (4) Dry the product formed in step (3) at 400°C for 2.5 hours to dryness, then sinter at 800°C for a certain period of 2 hours, then drop to room temperature, then coat with one millimeter of nano-scale silicon powder, and heat it at 1150°C for two hours. ...

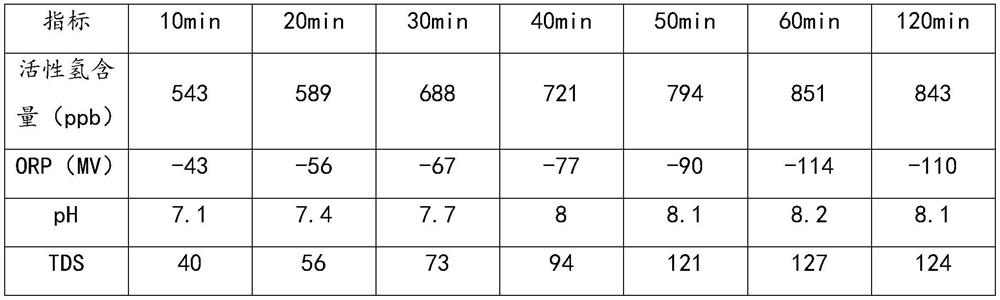

Embodiment 2

[0038] A preparation method of graphene hydrogen-rich ceramic balls, comprising the following steps:

[0039] (1) In parts by weight, take 1 part of platinum, 1 part of iron, 1 part of zinc, 1 part of magnesium, 1 part of silicon, mix with 1 part of graphene and 10 parts of alcohol, and grind it into a slurry in a pressure tank, The pressure in the pressure tank is 500kpa;

[0040] (2) Spray and granulate the slurry of step (1) in a spray granulation tower to make micron-scale micro-battery material;

[0041] (3) Add electrolyte to the micro-battery material of step (2), stir and mix in a mixer; wherein the electrolyte is calculated in parts by weight: 2 parts of sodium chloride, 2 parts of ammonium chloride;

[0042] (4) Add deionized water to the product mixed in step (3) for molding treatment. The amount of deionized water added here can be flexibly increased or decreased. Generally, 10 parts by weight is added to ensure better molding;

[0043] (5) Dry the product formed...

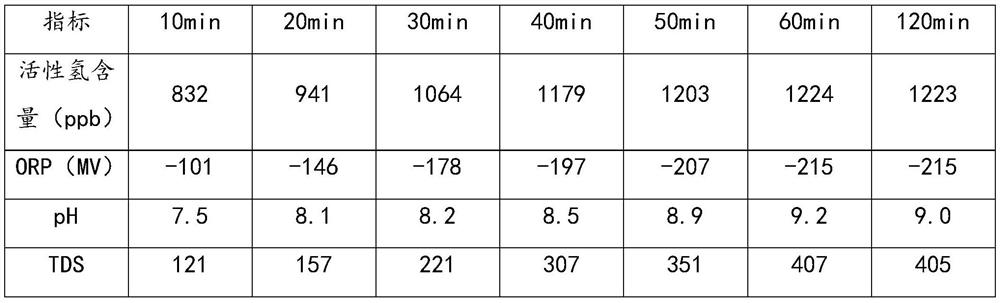

Embodiment 3

[0048] A preparation method of graphene hydrogen-rich ceramic balls, comprising the following steps:

[0049] (1) In parts by weight, take 4 parts of platinum, 3 parts of iron, 4 parts of zinc, 2 parts of magnesium, 3 parts of silicon, mix with 1 part of graphene and 14 parts of alcohol, grind into a slurry in a pressure tank, The pressure in the pressure tank is 500kpa;

[0050] (2) Spray and granulate the slurry of step (1) in a spray granulation tower to make micron-scale micro-battery material;

[0051](3) Add electrolyte to the micro-battery material of step (2), stir and mix in a mixer; wherein the electrolyte is calculated in parts by weight: 6 parts of sodium chloride, 5 parts of ammonium chloride, 30 parts of medical stone 25 parts of tourmaline, 30 parts of sepiolite, 7 parts of zeolite, 7 parts of albite, 7 parts of lithium feldspar, 7 parts of volcanic rock;

[0052] (4) Add deionized water to the product mixed in step (3) for molding treatment. The amount of dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com