Lithium borohydride tetrahydrofuran solution preparation method

A technology of tetrahydrofuran and lithium borohydride, applied in the directions of borane/diborane hydride, instruments, analytical materials, etc., to achieve the effects of mild reaction conditions, good safety, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of lithium borohydride tetrahydrofuran solution, comprising the following steps:

[0038] (1) Add 55g of potassium borohydride to 650mL of tetrahydrofuran and stir evenly;

[0039] (2) Add 47g of lithium chloride to step (1), raise the temperature to 24°C, and react for 8 hours;

[0040] (3) Filter the product obtained in step (2), and further distill the filtrate to obtain a lithium borohydride tetrahydrofuran solution with the required concentration.

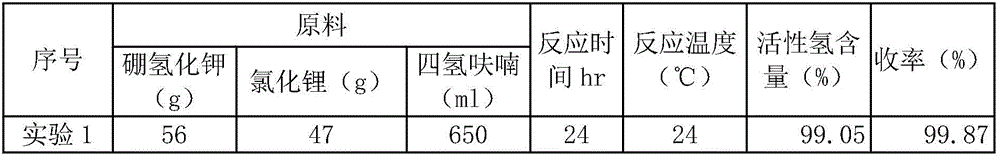

Embodiment 2-8

[0042] The steps are the same as in Example 1, and the amounts of reactants and the reaction conditions are shown in Table 1.

Embodiment 9

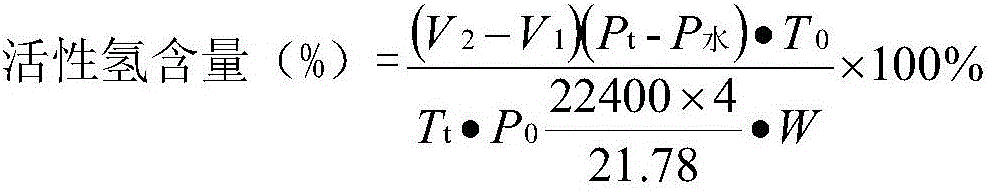

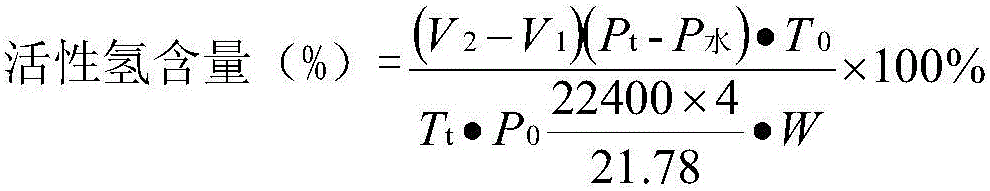

[0044] The assay method of the active hydrogen content of lithium borohydride in the lithium borohydride tetrahydrofuran that embodiment 1-8 makes:

[0045] (1) Distill the lithium borohydride tetrahydrofuran solution prepared in Examples 1-8 to remove tetrahydrofuran to obtain a lithium borohydride solid;

[0046] (2) Take a dry and clean Erlenmeyer flask and weigh it accurately, take the sample and put it in the Erlenmeyer flask, seal it tightly, and record it as W;

[0047] (3) The mixed solution of water and dioxane (the volume ratio of water: dioxane is 5:5) is added in the constant pressure funnel;

[0048] (4) The constant pressure funnel is connected with the Erlenmeyer flask with the sample and the gas constant pressure capacity measuring instrument to form a closed system, write down the volume number of the scale tube in the gas constant pressure capacity measuring instrument, and record it as V 1 ;

[0049] (5) Place the Erlenmeyer flask containing the sample in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com