Dust suppression device for tundish operation

A tundish and dust technology, which is applied to the cleaning method of tools, the method of removing smoke and dust, and the method of preventing pollution, etc. problem, to achieve the effect of reducing load and sliding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

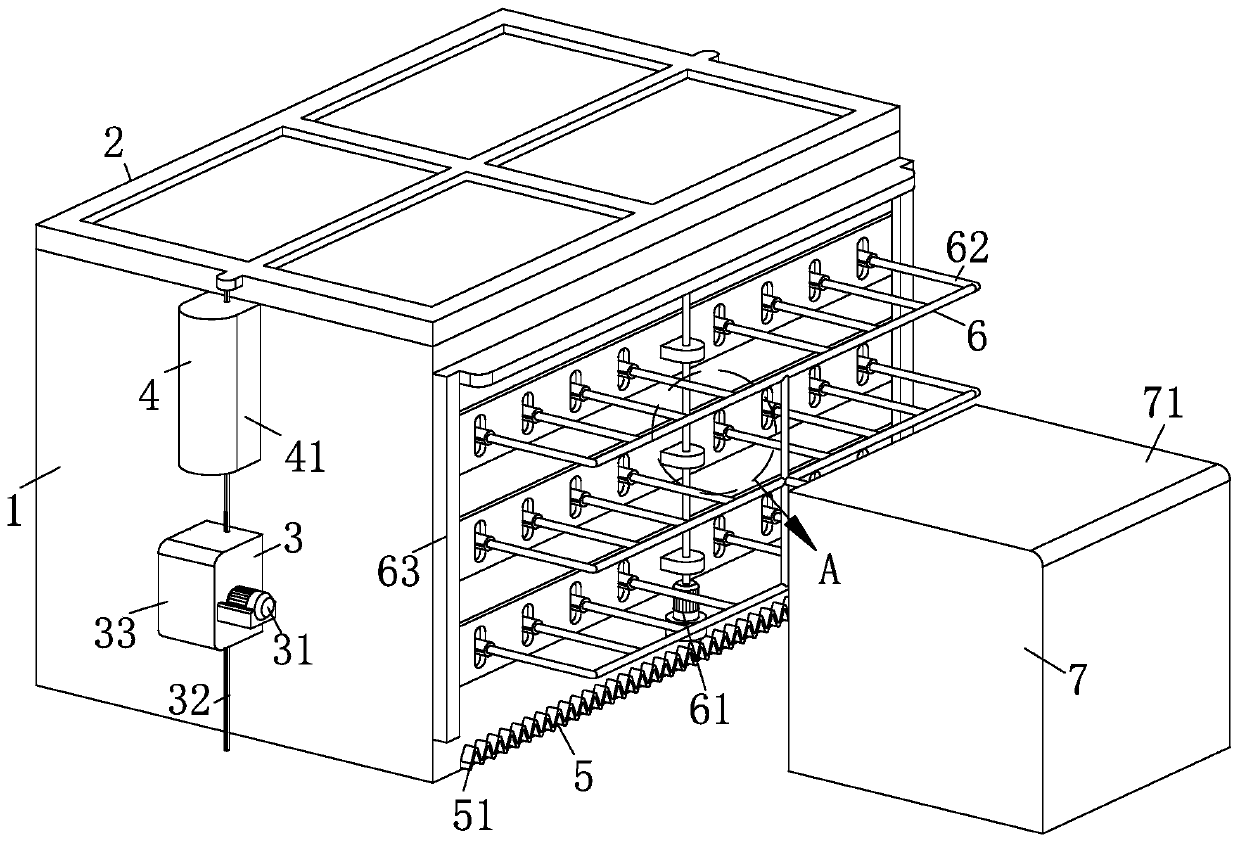

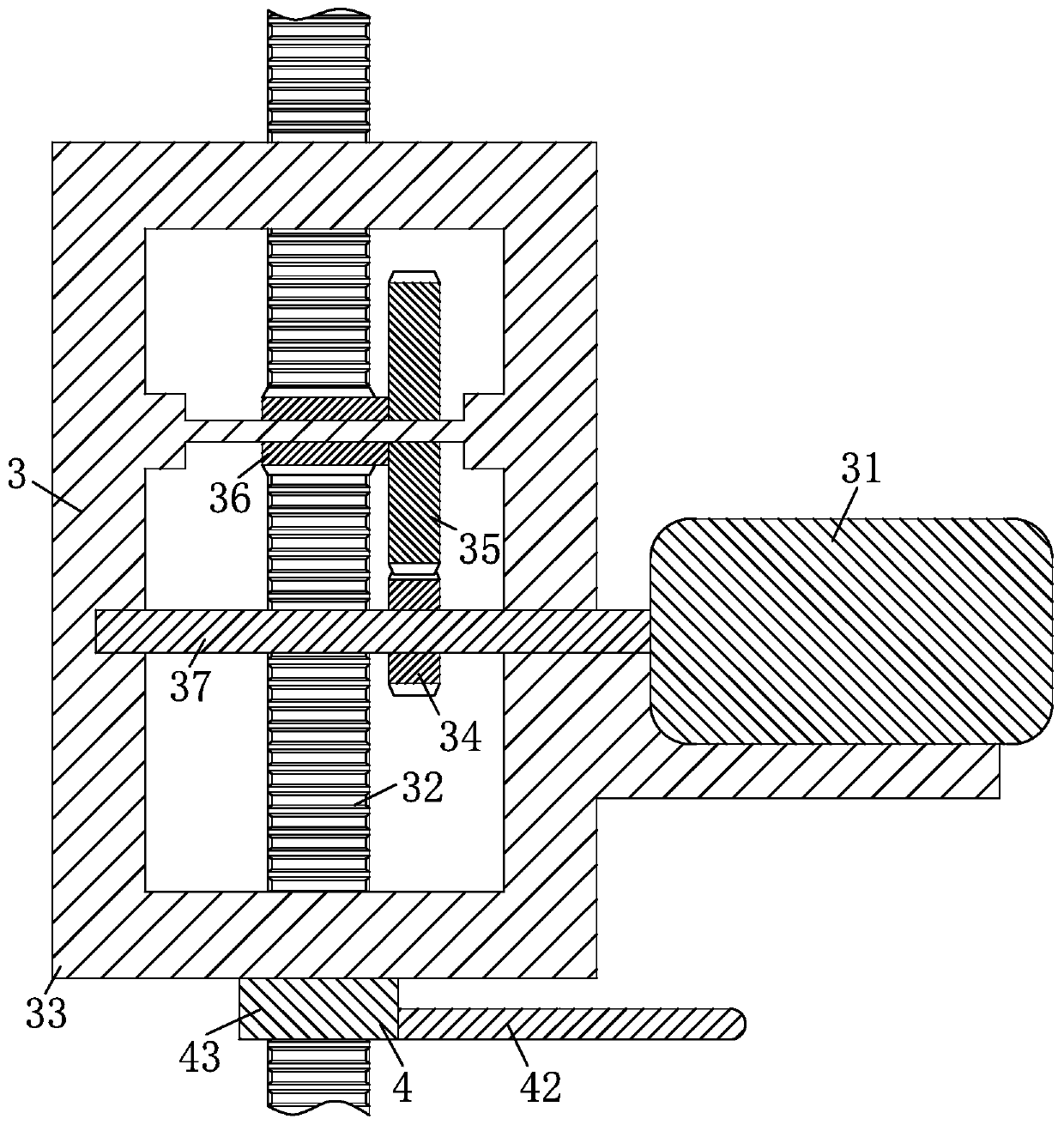

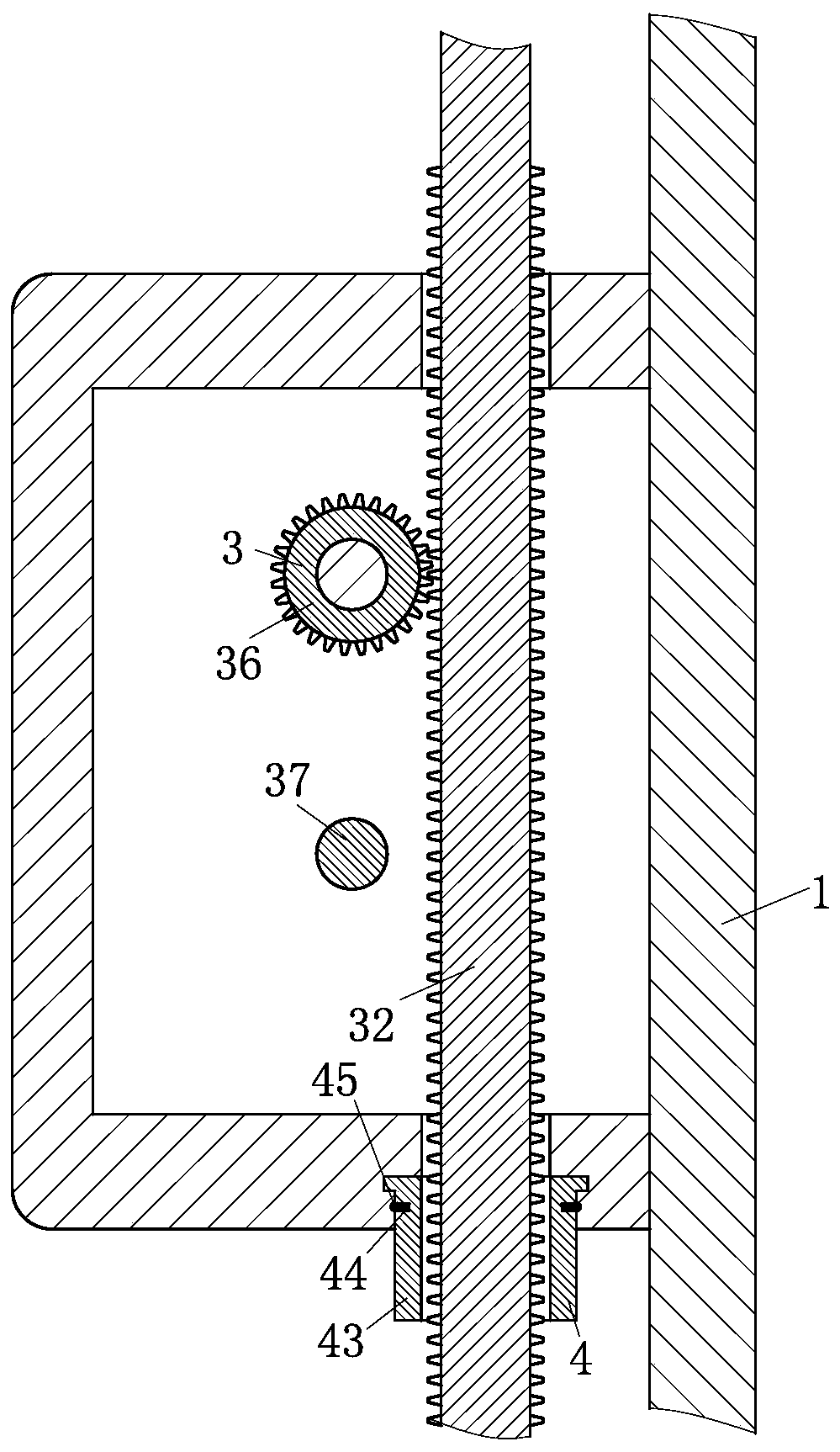

[0026] Such as Figure 1-Figure 8 As shown, a device for suppressing dust during tundish operation according to the present invention includes a dust suppression chamber body 1, a movable enclosure 2, a driving structure 3, a supporting structure 4, a sealing structure 5, a dust suppression structure 6, The spray structure 7 and the dust barrier 8 are used to support the structure, and at the same time construct a relatively closed environment during the tundish operation process to block the influence of external strong winds. Movable enclosure 2, the bottom side of the movable enclosure 2 is connected with the dust curtain 8 for blocking explosive dust and reducing the moving speed of dust, and the two sides of the movable enclosure 2 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com