Isobutane dehydrogenation catalyst and preparation method and application thereof

A dehydrogenation catalyst, isobutane technology, applied in catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve the problem that the size of pore volume, pore size and specific surface area are difficult to control, mechanical strength and high temperature stability cannot be obtained. guarantee, unsatisfactory catalytic activity and stability, etc., to achieve the effect of slow relative deactivation rate, inhibiting the formation rate of carbon deposits, and good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

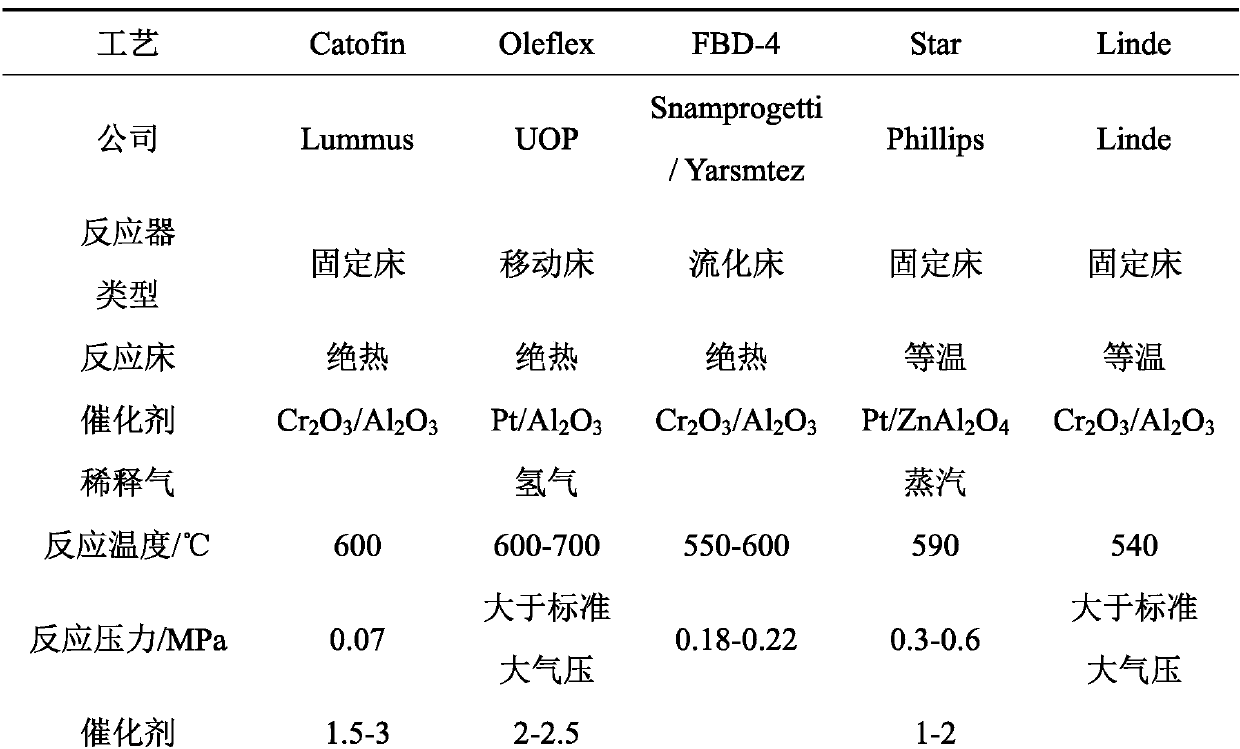

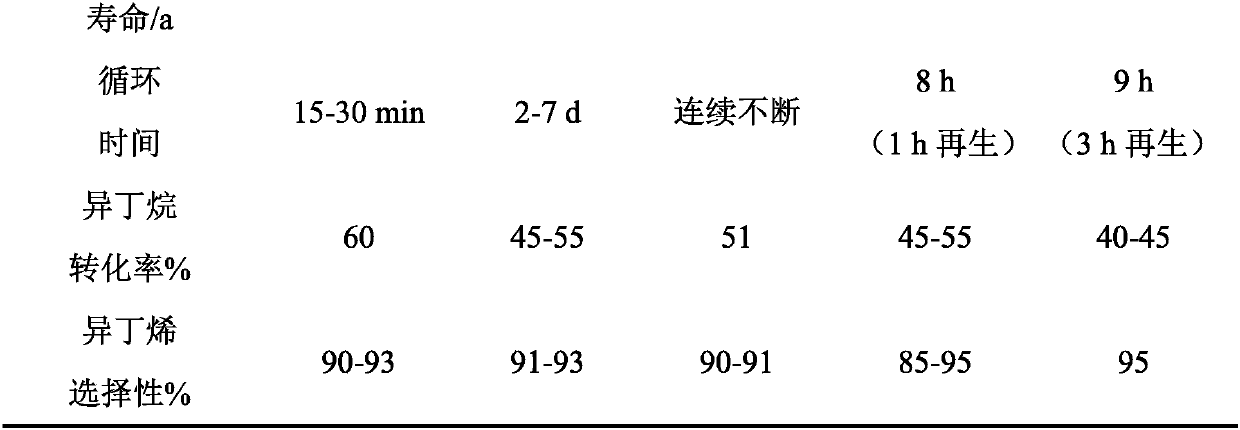

Image

Examples

preparation example Construction

[0029] With respect to the preparation method of isobutane dehydrogenation catalyst of the present invention:

[0030] Preferably, the soluble zinc salt is zinc sulfate, zinc chloride or zinc nitrate.

[0031] Preferably, the ratio of the soluble zinc salt, dilute ammonia water and citric acid is 15-75g: 10-20mL: 5-10g.

[0032] Preferably, the drying temperature in the steps (1), (3) and (4) is 80-120° C., and the drying time is 2-4 hours.

[0033] Preferably, the roasting time in the steps (1), (3) and (4) is 4-8h.

[0034] Preferably, the number of immersion in the step (1) is 1-3 times, and the time of each immersion is 4-8h.

[0035] With respect to the method for isobutene dehydrogenation of isobutane of the present invention:

[0036] Preferably, the heating rate is 2-5°C / min.

[0037] Preferably, the volume space velocity of the isobutane is 200-1000h -1 , more preferably 600h -1 .

[0038] Preferably, the molar ratio of isobutane to hydrogen is 1-10:1, more pre...

Embodiment 1

[0040] (1) 18.27g zinc nitrate (Zn(NO 3 )2 ·6H 2 O) Dissolve in 50mL deionized water, add 10mL dilute ammonia water (25%) and 5g citric acid and stir to form a complex solution, then put 95g industrially shaped γ-Al 2 o 3 Put the ball into the prepared complexing solution, dipping temperature 20°C, dipping time 8h, dipping times 1 time; after drying at 120°C for 2h, program the temperature to 1000°C and roasting, roasting time 4h, to obtain ZnO-Al 2 o 3 Composite carrier, wherein the zinc oxide content in the prepared composite carrier is 5wt%.

[0041] (2) Weigh 0.55g chloroplatinic acid hydrate (H 2 PtCl 6 ·6H 2 O) be dissolved in 50mL deionized water, prepare H 2 PtCl 6 solution. Weigh 0.45g stannous chloride hydrate (SnCl 2 .2H 2 O) be dissolved in 50mL deionized water, prepare SnCl 2 solution.

[0042] (3) The prepared ZnO-Al 2 o 3 Put the composite carrier into the coating device, adjust the temperature of the drum of the coating device to 60°C, and slowly...

Embodiment 2

[0045] The preparation method of catalyzer is similar to embodiment 1, and difference changes the step (1) of embodiment 1 into 36.5g zinc nitrate and is dissolved in 50mL deionized water, adds 10mL dilute ammonia water (25%) and 5g citric acid and Stir to make a complex solution, and then put 90g of industrial molding γ-Al 2 o 3 Put the ball into the prepared complexing solution; other steps and conditions remain unchanged to prepare the catalyst of this example, wherein the zinc oxide content in the prepared composite carrier is 10wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com