Low-fat chocolate and production process thereof

A production process and technology for chocolate, applied in the direction of food ingredients as thickeners, cocoa, and food ingredients as taste improvers, etc., can solve the problems of low fat content, increased volume and high fat content in chocolate, and achieve low fat content, Avoid bulky effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

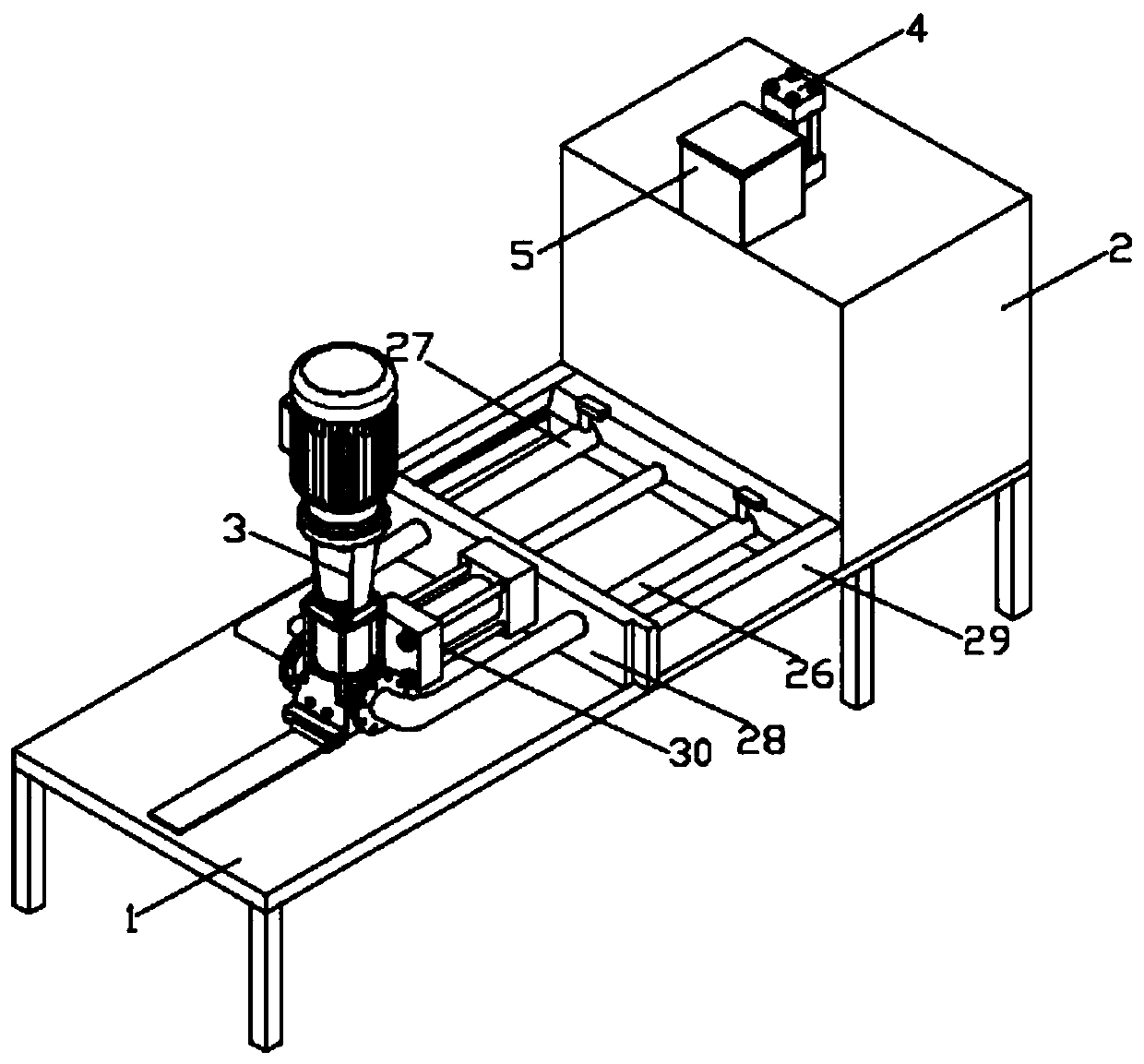

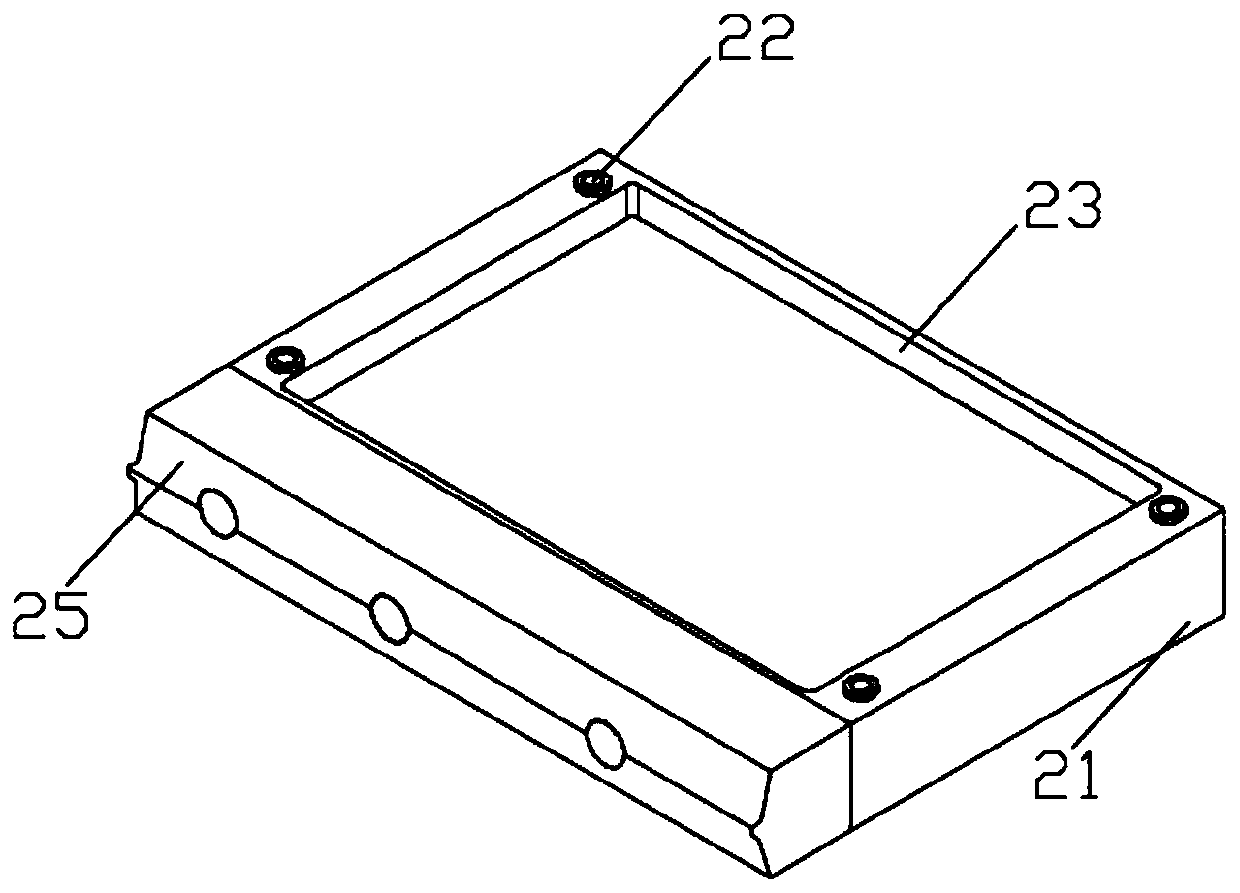

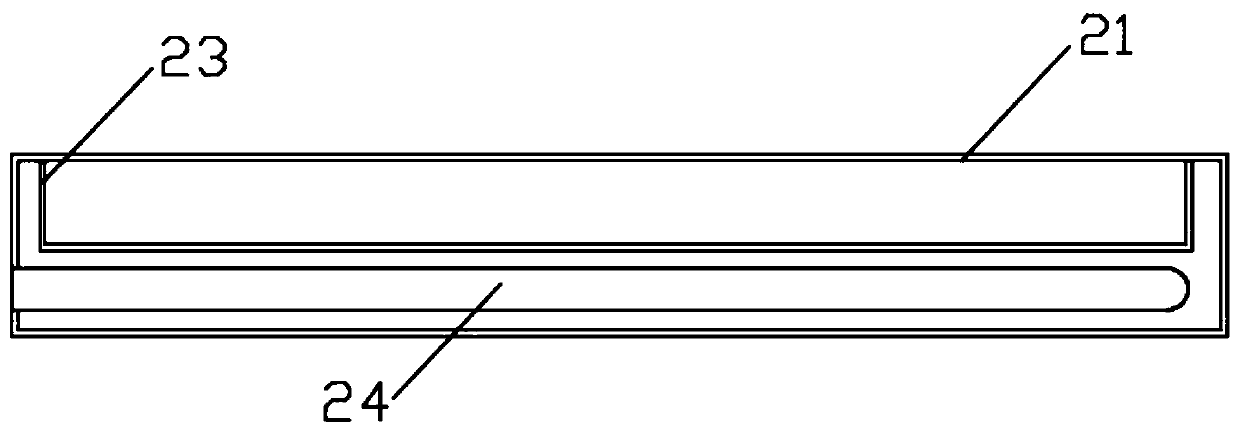

Image

Examples

Embodiment 1

[0036] A low-fat chocolate prepared from the following raw materials in parts by weight: 12 parts of cocoa powder, 30 parts of white sugar, 10 parts of skim milk powder, 0.15 parts of whey protein, 0.002 parts of xanthan gum, 1 part of vegetable oil, and 0.5 parts of maltitol part, water 1 part;

[0037] Wherein, the low-fat chocolate is prepared through the following steps:

[0038] Step 1: Weigh xanthan gum and put it into a high-mixer, and pour hot water into the high-mixer to stir. After stirring, a material liquid 1 is obtained, and take it out for later use;

[0039] Step 2: Weigh water and whey protein powder, pour water into the whey protein powder for heat treatment, put it into a high-mixer after heat treatment, and stir to obtain material liquid 2, take it out for later use;

[0040] Step 3: Pour material liquid 1 and material liquid 2 into the high mixer, add white sugar, skimmed milk powder, and maltitol and stir to obtain a mixed liquid, take it out for later us...

Embodiment 2

[0046] A low-fat chocolate prepared from the following raw materials in parts by weight: 15 parts of cocoa powder, 40 parts of white sugar, 15 parts of skimmed milk powder, 1 part of whey protein, 0.02 part of xanthan gum, 2 parts of vegetable oil, and 2 parts of maltitol 8 parts of water;

[0047] Step 1: Weigh xanthan gum and put it into a high-mixer, and pour hot water into the high-mixer to stir. After stirring, a material liquid 1 is obtained, which is taken out for later use; the mixing time of the high-mixer in step 1 is 8 minutes, The stirring speed is 7000r / min.

[0048] Step 2: Weigh the water and whey protein powder, pour water into the whey protein powder for heat treatment, put it into a high-mixer after heat treatment, and stir to obtain material liquid 2, take it out for later use; the heat treatment time in step 2 is 30 minutes , the heat treatment temperature is 85°C, the stirring time of the high mixer is 10min, and the stirring speed is 9000r / min.

[0049]...

Embodiment 3

[0053] A low-fat chocolate prepared from the following raw materials in parts by weight: 26 parts of cocoa powder, 60 parts of white sugar, 25 parts of skim milk powder, 1.8 parts of whey protein, 0.03 part of xanthan gum, 3 parts of vegetable oil, 2.5 parts of maltitol parts, 14 parts of water;

[0054] Step 1: Weigh xanthan gum and put it into a high-mixer, and pour hot water into the high-mixer to stir. After stirring, a material liquid 1 is obtained, which is taken out for later use; the mixing time of the high-mixer in step 1 is 10 minutes, The stirring speed is 8000r / min.

[0055] Step 2: Weigh water and whey protein powder, pour water into the whey protein powder for heat treatment, put it into a high-mixer after heat treatment, and stir to obtain material liquid 2, take it out for later use; the heat treatment time in step 2 is 45 minutes , the heat treatment temperature is 90°C, the stirring time of the high mixer is 15min, and the stirring speed is 10000r / min.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com