Capacitive touch white board

A capacitive touch and whiteboard technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve problems such as inaccurate clicks, slow response speed, etc., to achieve calculation and signal processing, attached Strong focus, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

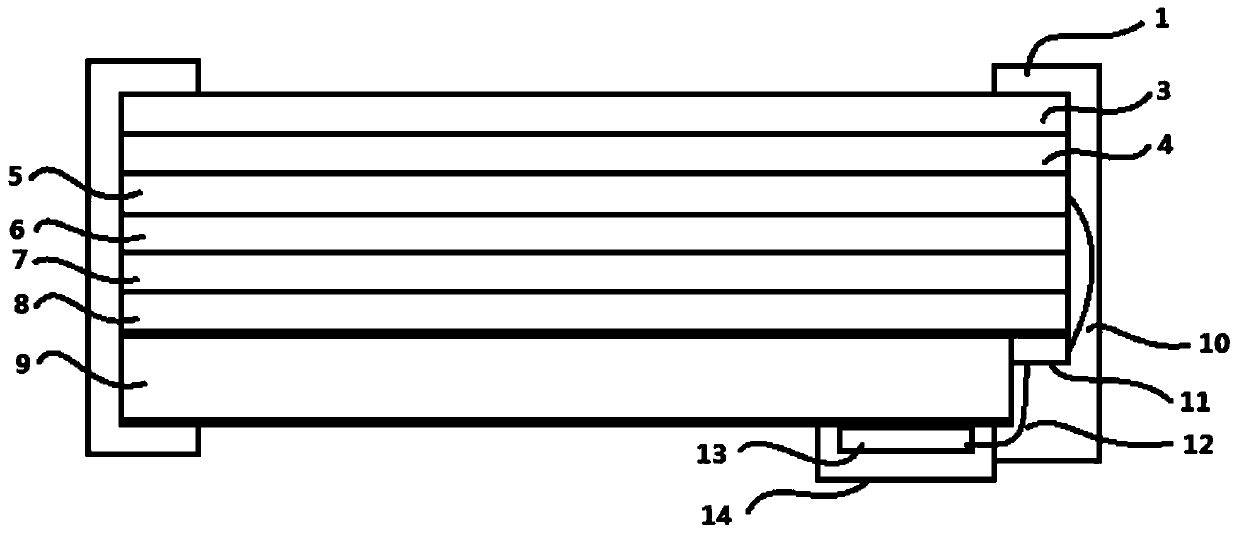

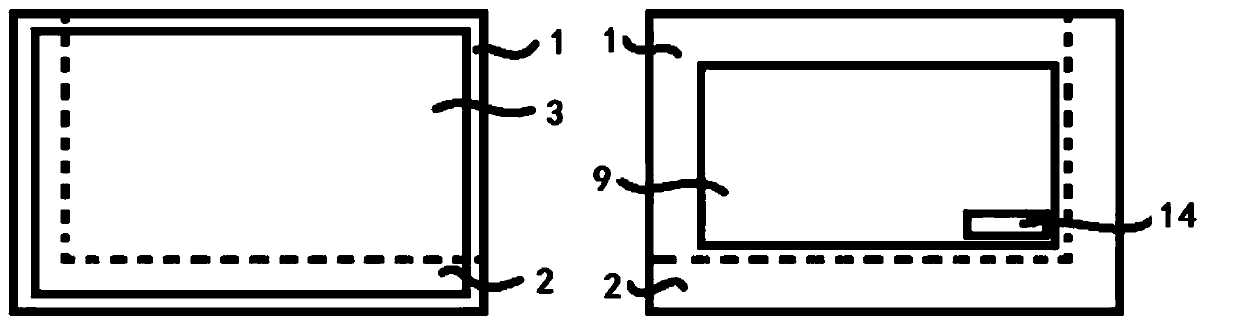

[0068] like Figure 1-2 As shown, it is an overall structural diagram of the present invention, including a panel 3, a capacitive sensing layer 5 and a support layer arranged in sequence, and the capacitive sensing layer 5 includes mutually perpendicular transmitting signal lines 17 and receiving signal lines 16, and the transmitting signal lines The intersection of the line 17 and the receiving signal line 16 forms a tiny capacitor, and the transmitting signal line 17 and the receiving signal line 16 are connected to the touch control board 13, and the touch control board 13 is used to change the value according to the capacitance of the tiny capacitor To locate the touch position, the touch control board 13 is connected to the host through an interface.

[0069] The capacitive sensing layer 5 is connected to the touch control main board 13 through an adapter board 11 . A fixed frame 1 is arranged outside the panel 3 , the capacitive sensing layer 5 and the supporting layer....

Embodiment 2

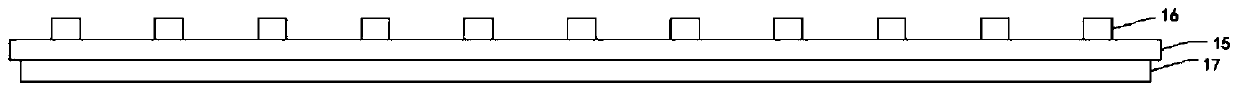

[0077] This embodiment provides a capacitive film, the schematic diagram of its front view structure is as follows image 3 As shown, it includes a PET substrate 15, a silk screen silver paste circuit (receiving signal line 16) arranged on the upper surface of the PET substrate 15, and a silk screen silver paste circuit (transmission signal line 17) arranged on the lower surface of the PET substrate 15. The silk screen silver paste lines on the surface and the silk screen silver paste lines on the lower surface are perpendicular to each other. In this embodiment, the size of the capacitor film is 96 inches, and the size of the PET substrate 15 used therein is 2182mm*2145mm.

[0078] In this embodiment, specifically, the PET substrate 15 is also called polyethylene terephthalate, which is a milky white or light yellow, highly crystalline polymer with a smooth and glossy surface. It has excellent physical and mechanical properties in a wide temperature range, excellent electric...

Embodiment 3

[0092] In this embodiment, the touch mainboard includes a main controller, N slave controllers, M drive controllers and power circuits, the slave controllers are used to process capacitive sensing signals, the drive controllers are used to drive capacitive sensing, and the The slave controller and the drive controller are connected to the flick through a small transfer board, and the power supply circuit is used to supply power to the touch control board.

[0093] like Figure 8 As shown, the touch main board includes a master controller, N slave controllers and M drive controllers, and the master controller is respectively connected to N slave controllers for synchronizing with the master controller and processing the capacitive sensing signals of each area through the I2C bus. The slave controller and the master controller are respectively connected to M driving controllers for synchronizing with the master controller and driving capacitive sensing in each area through the G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com