Multi-layer composite main cable protection tedlar tape

A multi-layer composite and wrapping tape technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of increasingly high airtightness of the main cable, and achieve the effects of high elasticity, isolation and erosion, and effective main cable protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

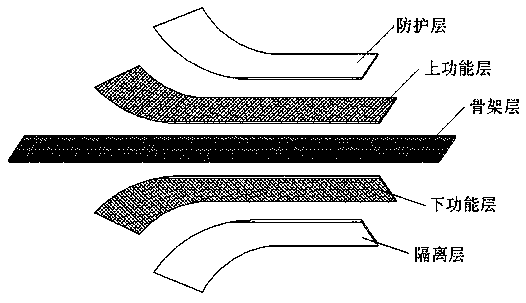

[0018] Example 1: The main material of the protective layer (1) and isolation layer (5) of the multi-layer composite main cable wrapping tape is saturated polyolefin thermoplastic elastomer, colorless and transparent, and the thickness of the film is 0.6 mm. The main material of the upper functional layer (2) and the lower functional layer (4) of the multi-layer composite main cable wrapping tape is chlorosulfonated polyethylene material, which has excellent weather resistance and heat air aging resistance, and has a good sealing effect. Design requirements The design is red, and the film thickness is 1.2mm. The wrapping tape can be vulcanized and cross-linked at 110°C.

Embodiment 2

[0019] Example 2: The main material of the multi-layer composite main cable wrapping tape protective layer (1) and isolation layer (5) is polyolefin ethylene propylene rubber, and the thickness of the film is 1mm. The main material of the upper functional layer (2) and the lower functional layer (4) of the multi-layer composite main cable wrapping tape is modified binary ethylene propylene rubber, which has good elasticity, sealing and weather resistance, and the thickness of the film is 1.4mm. The wrapping tape is designed in orange according to the design requirements. The wrapping tape can be vulcanized and cross-linked at 130°C.

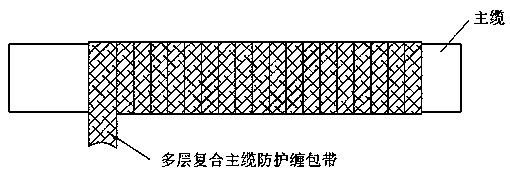

[0020] After testing, the multi-layer composite main cable wrapping tape is tightly lapped and bonded without gaps, which can effectively prevent internal gas leakage and realize the sealing, isolation and protection of the main cable. The construction is simple and meets the expected design requirements. Implementability and marketing value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com