Modified lithium nickel cobalt manganese oxide ternary positive electrode material and preparation method and application thereof

A technology of nickel-cobalt lithium manganese oxide and ternary materials, which is applied in the direction of positive electrodes, active material electrodes, electrical components, etc., can solve the problems of low capacity of ternary positive electrode materials, reduce the formation of SEI), stabilize performance, and alleviate Effects of excess lithium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] On the one hand, an embodiment of the present invention provides a method for preparing a modified nickel-cobalt-lithium manganese oxide ternary positive electrode material. The preparation method of the modified nickel-cobalt lithium manganese oxide ternary positive electrode material comprises the following steps:

[0023] Step S01: preparing a nickel-cobalt-lithium manganese oxide ternary material, the particles of which are braided spherical;

[0024] Step S02: The powder of the nickel-cobalt-lithium-manganese-oxide ternary material is mixed with the mixture of rare earth nitride and lithium-nitrogen in a mass ratio of 1:(0.05-0.3):(0.01-0.1) for the first ball milling process , to obtain the mixture powder;

[0025] Step S03: The mixture powder is sintered in stages under a nitrogen-oxygen mixed atmosphere.

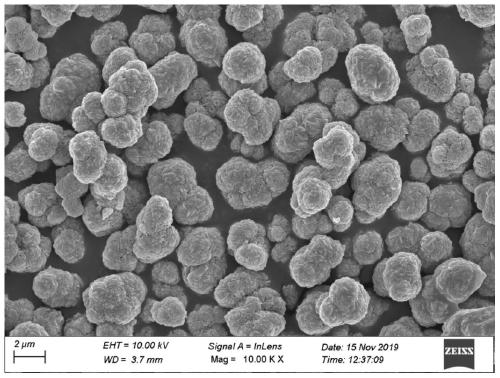

[0026] Wherein, in step S01, the particles of the nickel-cobalt-lithium-manganese-oxide ternary material are braided spherical, specifically as figure 1 wi...

Embodiment 1

[0041] This example provides a modified nickel-cobalt lithium manganate ternary positive electrode material and a preparation method thereof. The modified nickel-cobalt lithium manganese oxide ternary positive electrode material is prepared according to a method comprising the following steps:

[0042] (1) Preparation of nickel-cobalt-manganese ternary cathode material with braided ball structure:

[0043] Dissolve nickel nitrate, cobalt nitrate, and manganese nitrate in an amount of 6:2:2 in absolute ethanol, and add 500ml of NH 4 OH solution, the pH value is controlled at 11, the reaction temperature is 45°C, and the stirring rate is 750r / min. After 12 hours of reaction, filter, wash, dry at 55°C for 14 hours, and grind to obtain a nickel-cobalt-manganese ternary precursor with a braided ball structure; The precursor of the above braided ball structure is mixed with lithium carbonate at a ratio of 1:1.08. After mixing and grinding, it is pre-fired at 450°C for 5 hours in an...

Embodiment 2

[0047] This example provides a modified nickel-cobalt lithium manganate ternary positive electrode material and a preparation method thereof. The modified nickel-cobalt lithium manganese oxide ternary positive electrode material is prepared according to a method comprising the following steps:

[0048] (1) Preparation of nickel-cobalt-manganese ternary positive electrode material with braided ball structure: as in step (1) of Example 1;

[0049] (2) Preparation of NCM622 coated with a mixture of zirconium nitride and lithium nitrogen:

[0050] Weigh zirconia and carbonamide at a ratio of 1:0.1, ball mill at a rate of 300r / min for 50min, and heat up to 550°C for 2h at a rate of 5°C / min in a nitrogen atmosphere to obtain powder 1; lithium carbonate and carbon The amide was weighed at a ratio of 1:0.08, heated to 650°C for 2 hours at a heating rate of 5°C / min in a nitrogen atmosphere, and ball milled at a rate of 300r / min for 50 minutes to obtain powder 2; mix NCM622 with powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com