Preparation method of gallium nitride molybdenum disulfide mixed-scale pn junction

A gallium nitride and molybdenum sulfide technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unsatisfactory test requirements and low yield, and achieve simple operation, small damage, and obvious rectification effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

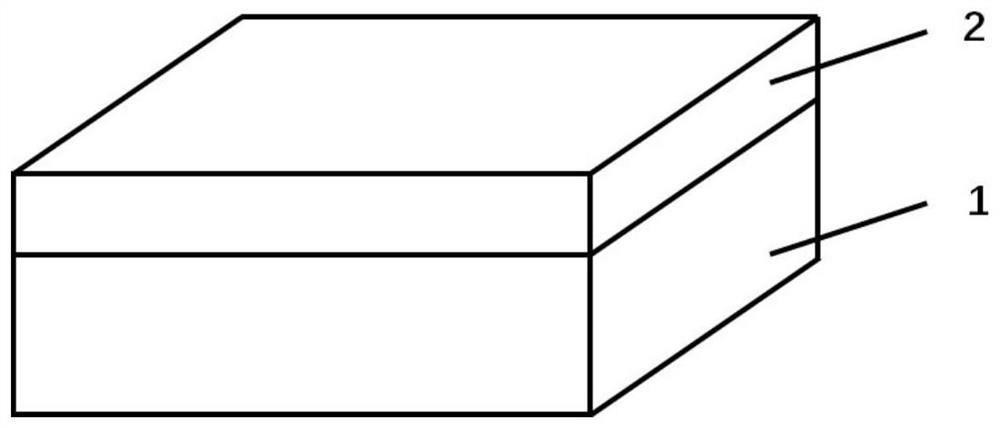

[0026] (1) PA-MBE method deposits 400-500nm p-GaN on sapphire substrate, growth method: metal gallium and nitrogen are used as Ga source and N source respectively, and the growth temperature is 890°C; N 2 The flow rate is 0.7sccm, the power is 450W; the Ga source temperature is 1050°C, and metal magnesium is used as the Mg source, and its temperature is 240°C. When the temperature rises to the desired temperature, first open the Ga baffle to grow a fresh GaN layer on the substrate surface for 2 minutes, then open the Mg baffle to start growth, and the growth time is 2 hours;

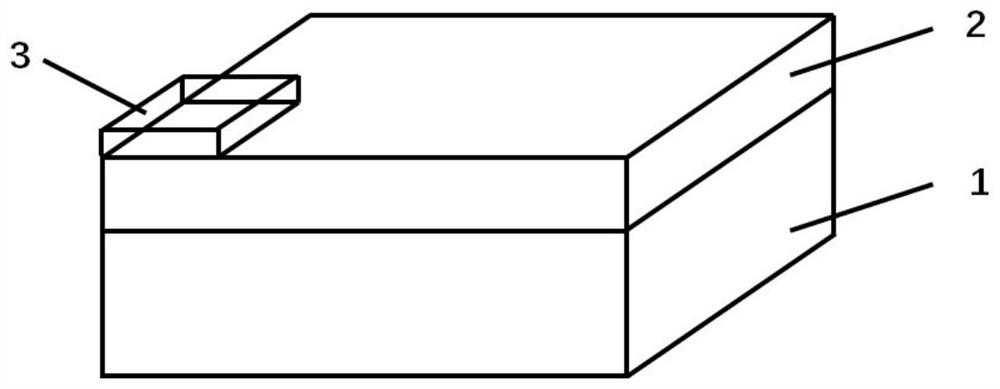

[0027] (2) Prepare Ti / Al / Ni / Au alloy electrodes on p-GaN by physical vapor deposition, the thickness of which is 30nm / 150nm / 50nm / 100nm, and then perform rapid annealing treatment on the sample in an annealing furnace under the condition of 800 °C, N 2 atmosphere, forming an ohmic contact with p-GaN;

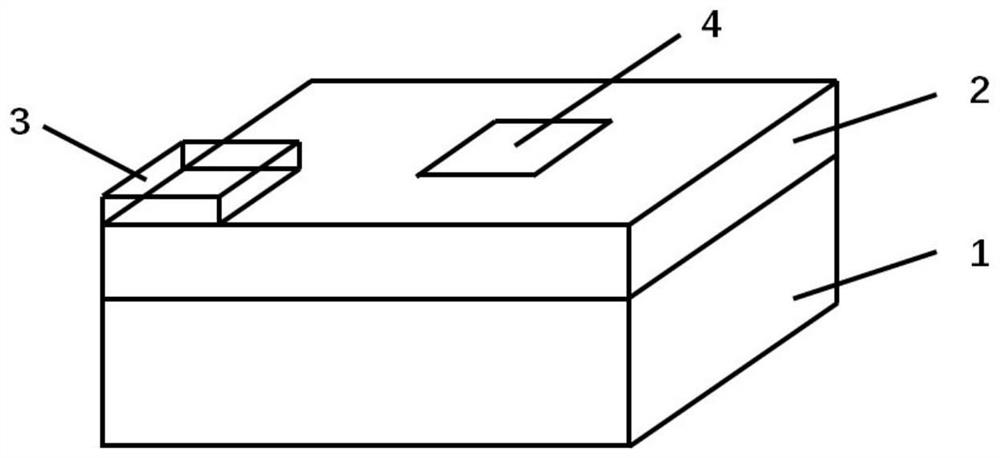

[0028] (3) Place PDMS (polydimethylsiloxane, model PF-40 / 17-X4, produced by Gel Pak Company of the Uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com