Mold design template of refractory product and method for automatically checking mold cost

A refractory product and mold design technology, applied in the direction of design optimization/simulation, can solve the problems of low design efficiency, large deviation value, time-consuming and labor-intensive, etc., and achieve the effect of improving automation and work efficiency, reducing professional threshold, and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

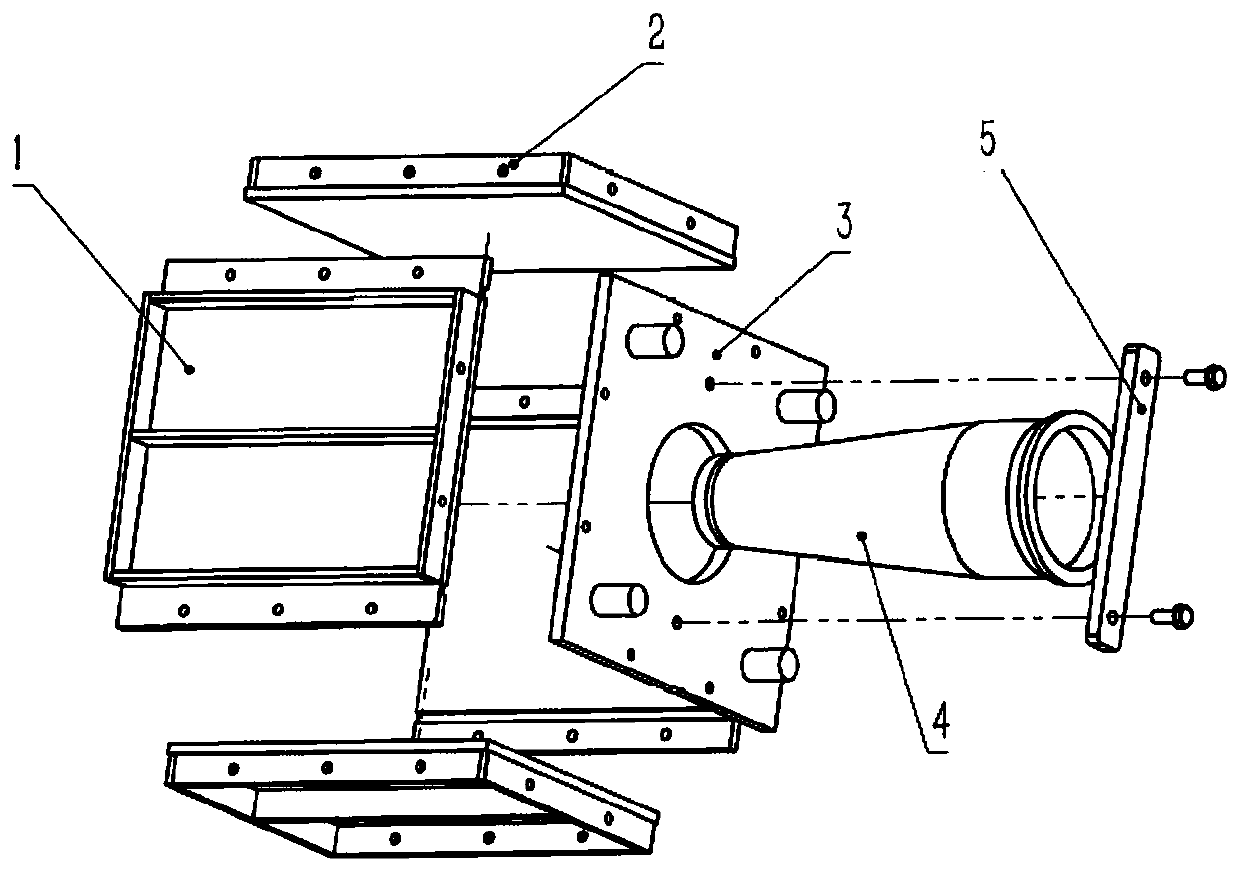

[0025] The specific steps of the refractory product mold drawing design template and the method for automatically calculating the mold cost of the present invention will be further described in detail below in conjunction with the accompanying drawings.

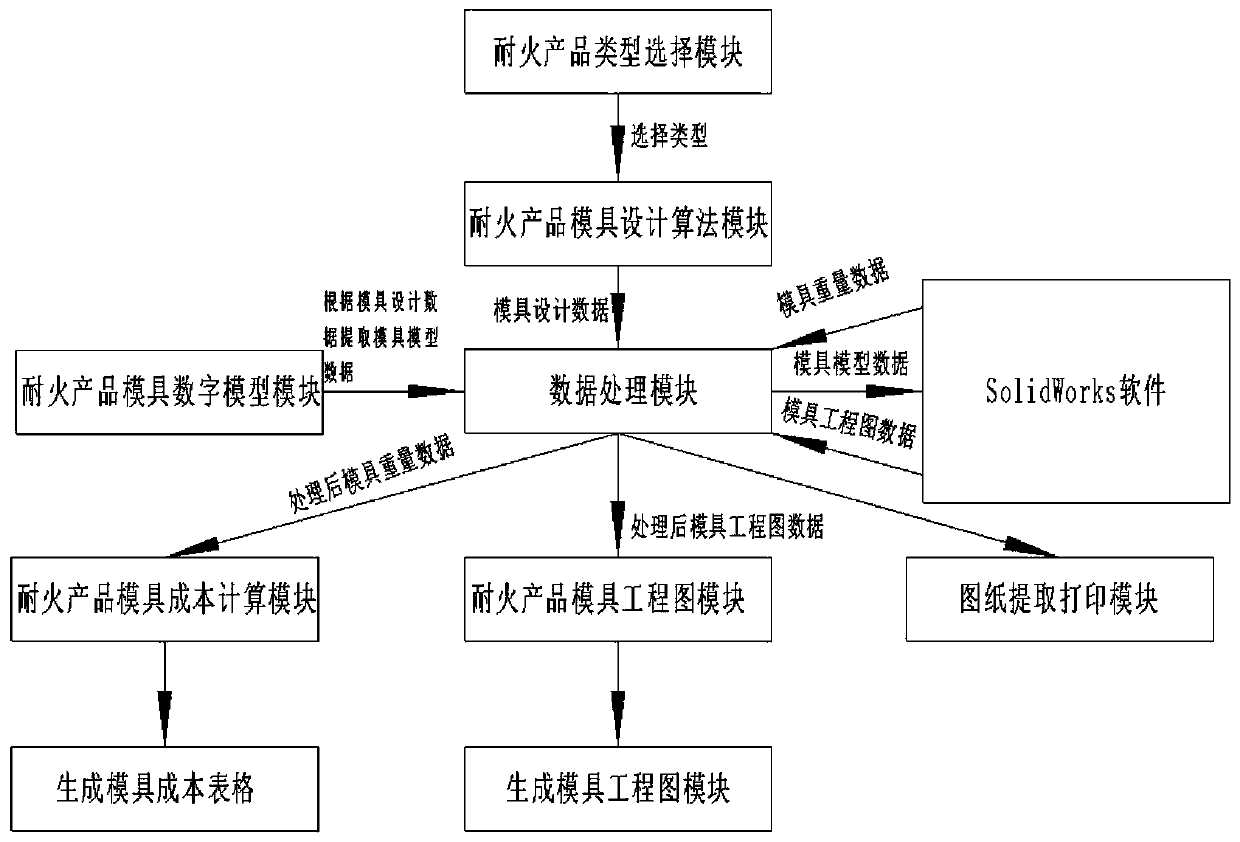

[0026] Such as figure 2 Shown is the specific operation flowchart of implementing the method of the present invention.

[0027] The refractory product mold drawing design template and the method for automatically calculating the mold cost of the present invention, the steps include:

[0028] S1, use VB.net or C# and other development tools that support COM programming, and call the API (Application Programming Interface) function provided by SolidWorks (a 3D CAD / CAM system based on Windows) to perform secondary development on SolidWorks, combining Refractory product mold design rule algorithm, compiled into .EXE file or generate SolidWorks plug-in;

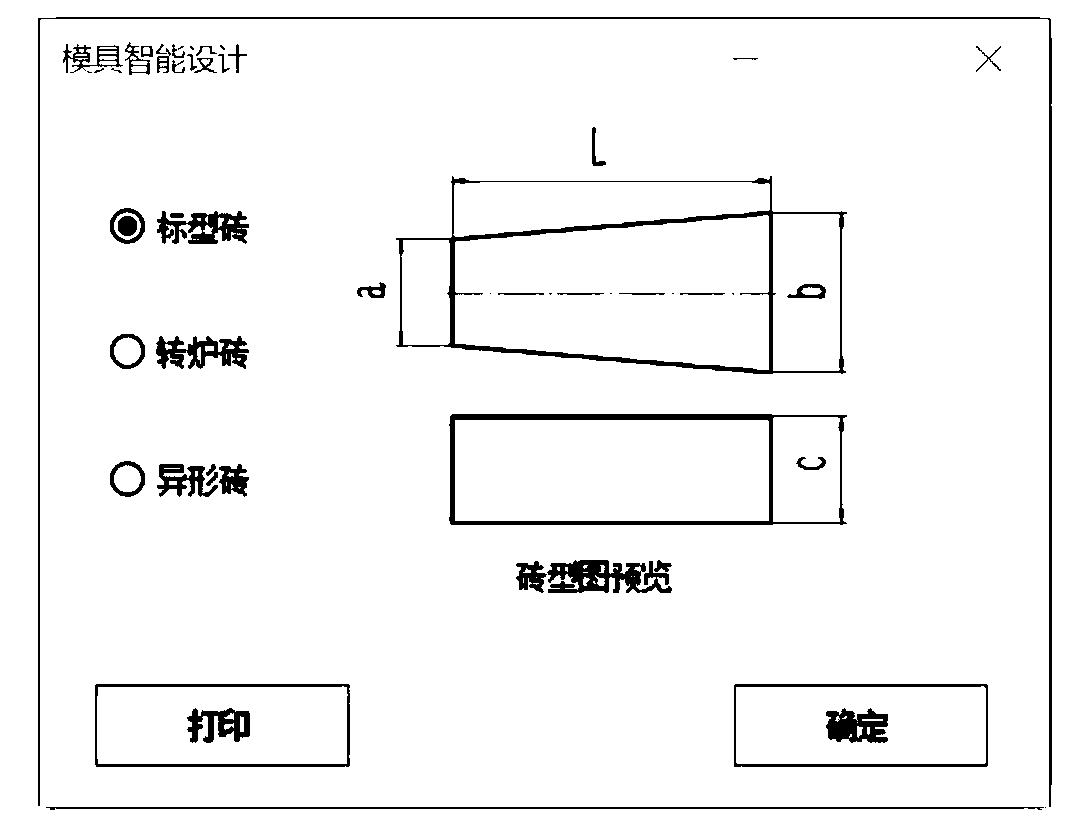

[0029] S2, the user selects the type of refractory product to be designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com