A Construction Method for Asymmetric Curtain Wall Structure of Greenhouse Pavilion

A construction method and asymmetric technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex construction process, long construction period, single form of glass curtain wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

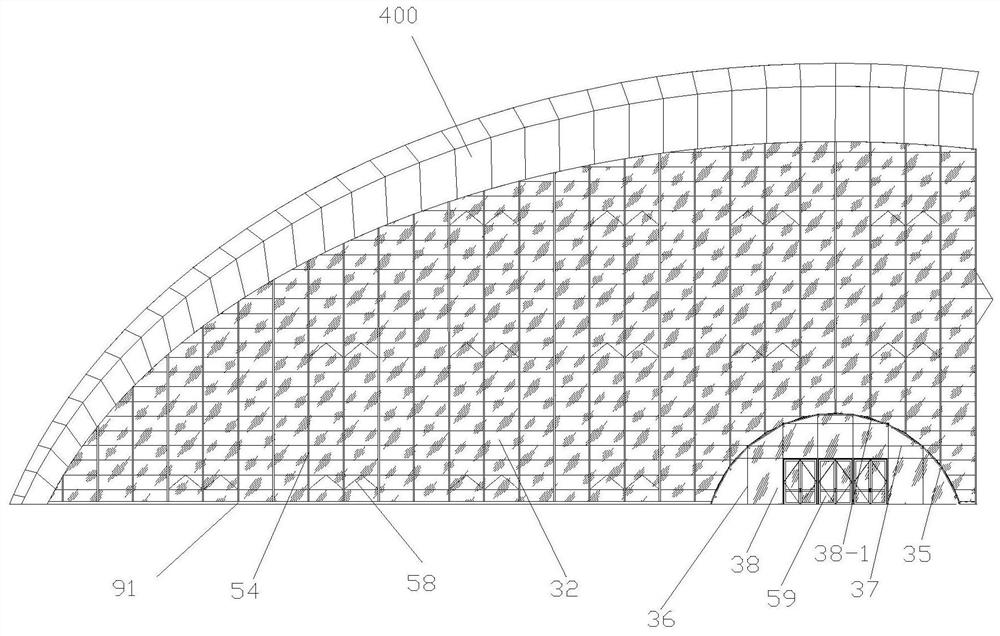

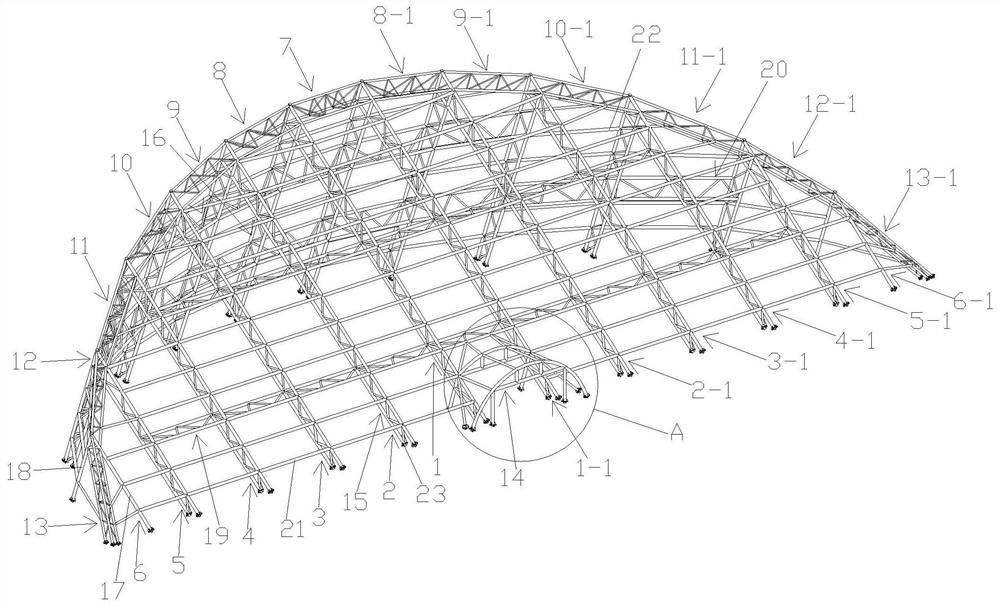

[0213] like Figure 1 to Figure 12 Shown, the present invention comprises the following steps:

[0214] Step 1. Processing of the main truss:

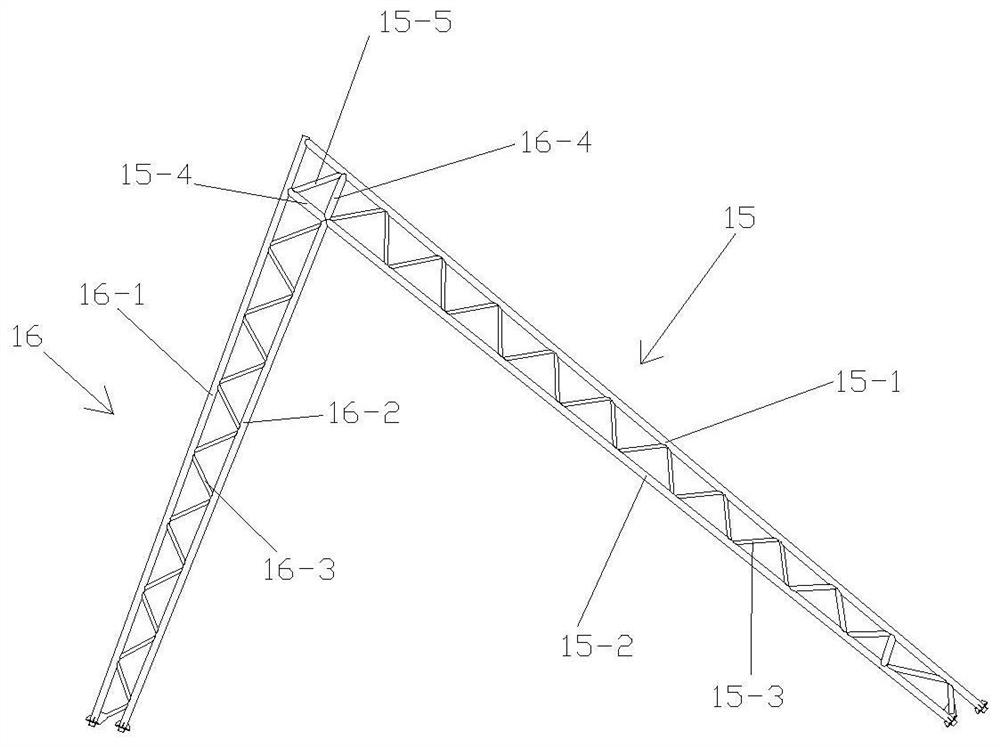

[0215] Step 101, install the front web steel pipe 15-3 between the front upper chord steel pipe 15-1 and the front lower chord steel pipe 15-2, and process it into the front truss 15; wherein, the number of the front web steel pipe 15-3 is multiple;

[0216] Step 102, install the rear belly steel pipe 16-3 between the rear upper chord steel pipe 16-1 and the rear lower chord steel pipe 16-2, and process it into the rear truss 16; wherein, the number of rear belly steel pipes 16-3 is multiple;

[0217] Step 103, fixing the top of the rear truss 16 and the top of the front truss 15 to obtain the main truss;

[0218] Step 104, according to the method described in step 101 to step 103, complete the processing and manufacture of multiple main trusses, and record the multiple main trusses as the first left truss 1, the second left truss 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com