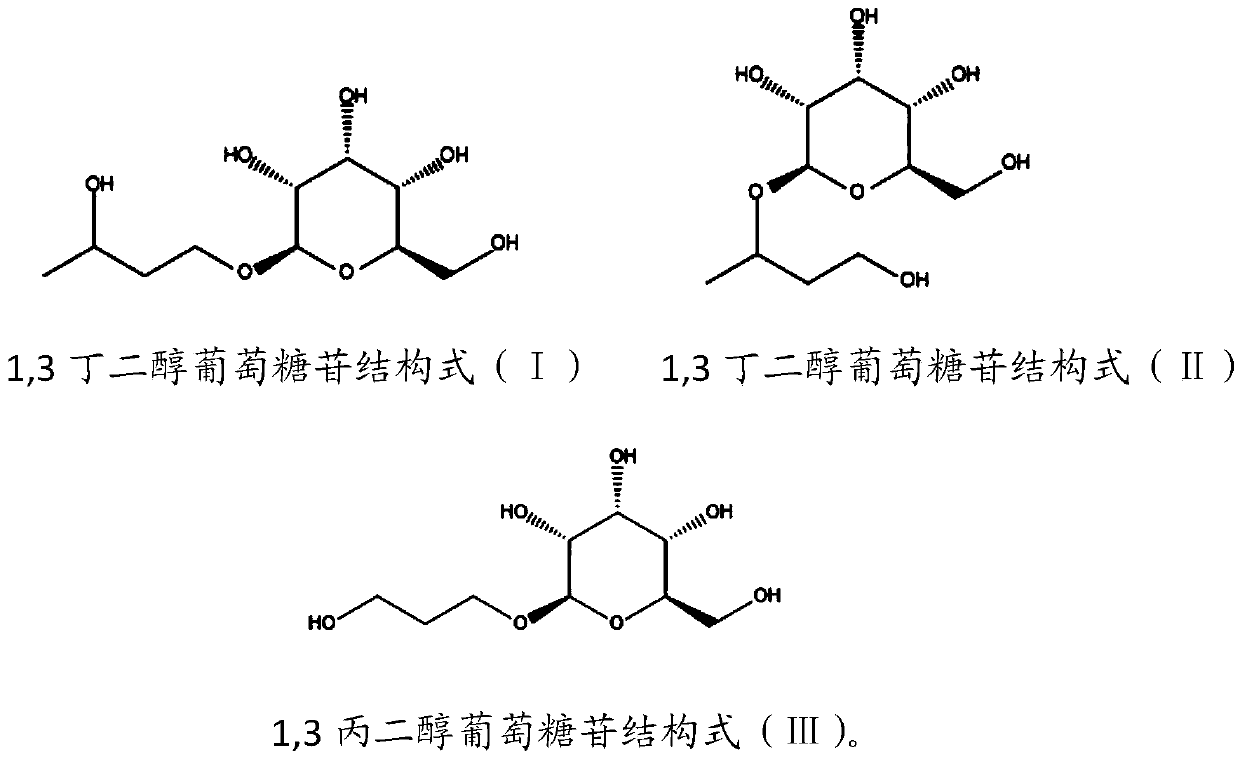

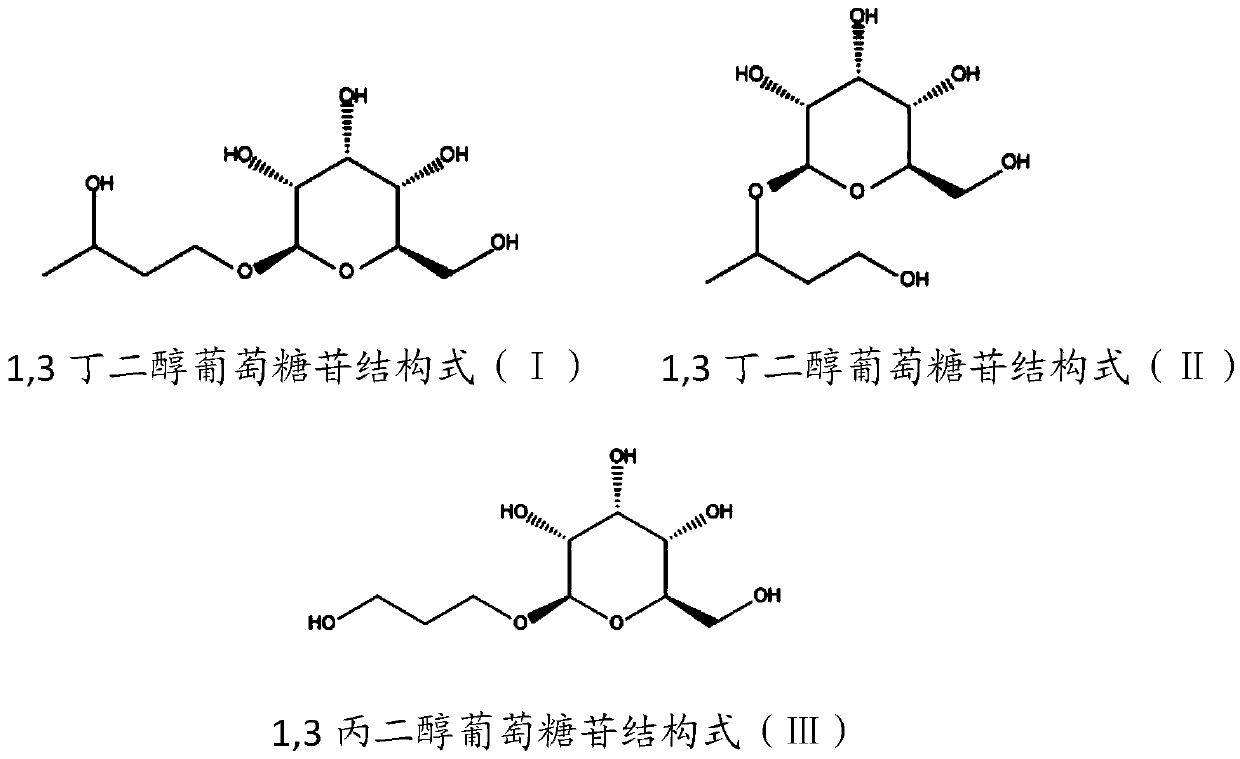

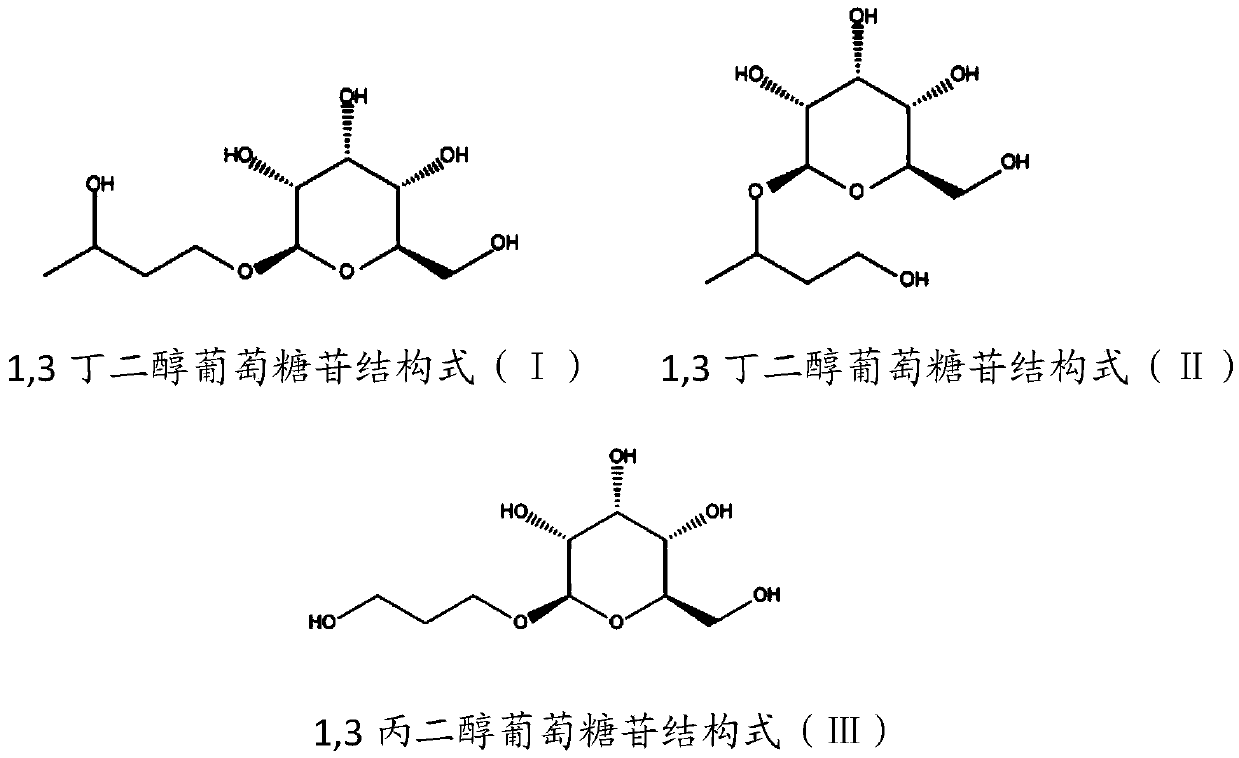

Polyhydric alcohol glucoside, and preparation method and application thereof

A technology of glucoside and polyol, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of skin irritation, solvent residue, heavy metal ion residue, etc., and achieve simple reaction steps and conditions, No chemical solvent residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also relates to a preparation method of a class of polyol glucoside, comprising the following steps:

[0019] Step 1: Add 1,3 propylene glycol or 1,3 butanediol and glucose into the reactor, and heat until the glucose is completely dissolved;

[0020] Step 2: After the glucose is completely dissolved, add the acidic catalyst into the reactor, keep the temperature at 95°C-120°C, and carry out the decompression reaction at 0.08Mp;

[0021] Step 3: After 6 hours of reaction, the condenser no longer separates water, and the reaction is completed. Add an acid neutralizer into the reactor to adjust the pH value of the reaction system in the reactor to 4.5-6.5, and cool to 15-30°C. Produce 1,3 propanediol glucoside or 1,3 butanediol glucoside.

[0022] Preferably, in the step 1 of the above-mentioned preparation method of polyol glucoside, the molar ratio of 1,3 propanediol or 1,3 butanediol to glucose is 10:1˜2:1.

[0023] Preferably, in the step 1 of ...

Embodiment 1

[0030] Weigh 40g of glucose and 160g of 1,3-butanediol (the molar ratio of 1,3-butanediol to glucose is 8:1), put them into the reactor, turn on the heating temperature at 95°C, wait until the glucose is completely dissolved, and pour into the reactor Add 0.1N concentrated sulfuric acid, turn on the vacuum to carry out the decompression reaction, adjust the pH of the system to 4.5 with 0.3% sodium hydroxide after the reaction is completed, distill off excess 1,3 butanediol with a thin film evaporator, and cool to 15°C 52 g of 1,3-butanediol glucoside was obtained with a yield of 92.8%.

Embodiment 2

[0032] Weigh 50g of glucose and 150g of 1,3-butanediol (the molar ratio of 1,3-butanediol to glucose is 6:1), put them into the reactor, turn on the heating temperature of 110°C, wait until the glucose is completely dissolved, and pour into the reactor Add 0.15N p-toluenesulfonic acid, turn on the vacuum to carry out the decompression reaction, adjust the pH of the system to 5.2 with 0.25% potassium hydroxide after the reaction, distill off the excess 1,3 butanediol with a thin film evaporator, and cool to At 25°C, 67 g of 1,3-butanediol glucoside was obtained, with a yield of 95.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com