Method for preparing granularity-adjustable lithium iron phosphate positive electrode material

A technology for adjusting lithium iron phosphate and cathode materials, which is applied in chemical instruments and methods, battery electrodes, phosphorus compounds, etc., can solve problems such as retention, and achieve the effects of improving reaction uniformity, ensuring sintering completion, and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

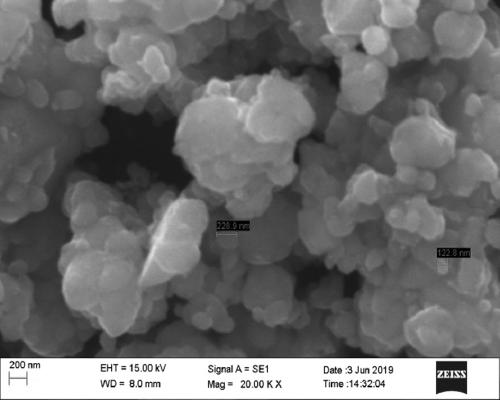

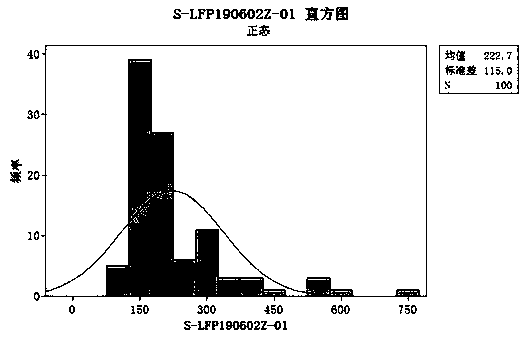

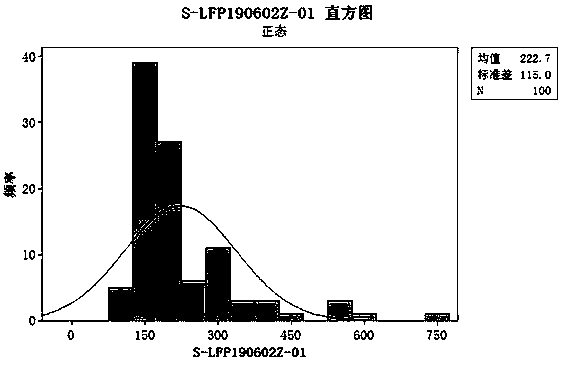

[0022] 1) Select batches with a water content of less than 0.5wt% raw material iron phosphate, in which the iron content is 36.10wt%, and the phosphate content is 63.85wt%. According to the mass ratio of 1:0.25:0.1, take 2 kg of ferric phosphate, lithium carbonate and glucose dry matter in total, configure it as a slurry with a solid content of 35wt%, and use a sand mill to circulate sand, and the sand mill is equipped with 0.3mm zirconium beads, so that The final refined particle size D50 is about 350nm;

[0023] 2) Turn on the spray dryer, adjust the air inlet temperature of the spray dryer to 230°C, and the outlet air temperature to 95°C, and then carry out atomization and drying of the above slurry at a pump speed of about 100g / min to obtain a median The particle size is about 18μm microspheres.

[0024] 3) The above-mentioned dried materials are transferred to a closed intermittent rotary sintering furnace, and the intermittent rotary sintering furnace is used for high-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com