Welding method and welding equipment for X-ray tube beryllium window

A technology for X-ray tubes and welding equipment, which is applied in the field of welding methods and welding equipment for beryllium windows of X-ray tubes, can solve the problems of poor wettability and fluidity of the beryllium surface, high processing costs, and voids in the weld seam interface, and achieve saving and increasing Pressing equipment, increasing the number of processing, reducing the effect of heat treatment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

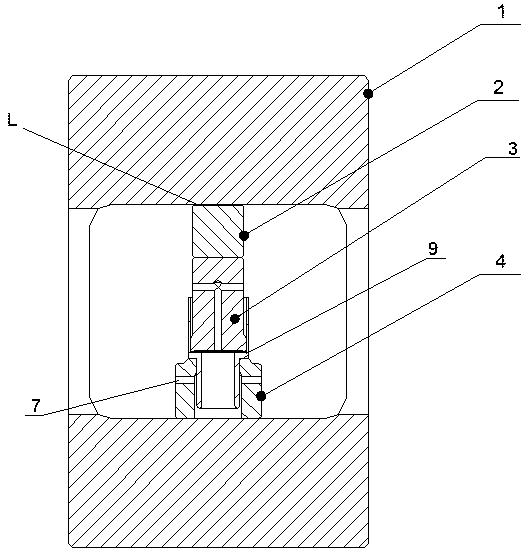

[0029] The present application will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present application and the present application is not limited to the following examples. The sides and front and back mentioned in this application are relative to figure 1 In terms of.

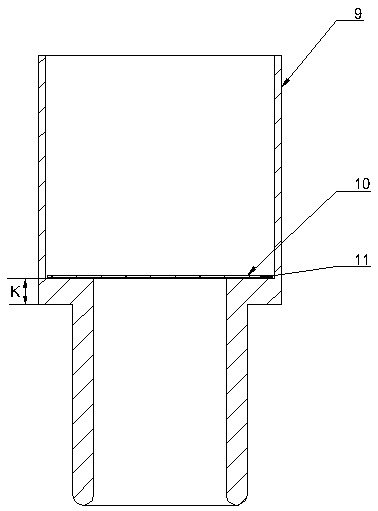

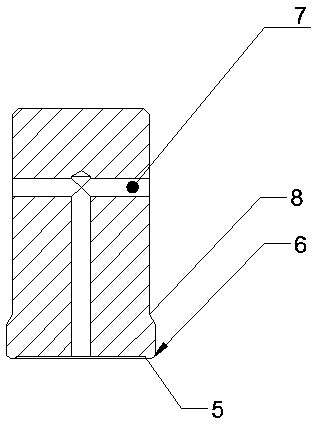

[0030] see Figure 1 ~ Figure 4 , the beryllium window processing part of the X-ray tube in this embodiment is composed of a beryllium window bracket 9, a beryllium sheet 10, and a solder 11. The X-ray tube beryllium window welding equipment (tooling) includes a frame 1 (middle and peripheral ventilation structure), a plug 2 , briquetting block 3, cushion block 4. Wherein the briquetting block 3 is provided with a pressing step 5, and the edge of the pressing step 5 has a chamfer 6, and the briquetting block 3 and the cushion block 4 are all provided with vent holes 7, equipped with a height (refer to figure 1 U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com