Silver nanoflake cluster array and preparation method thereof

A technology of silver nanosheets and arrays, which is applied in the field of preparation of precious metal micro-nano structures, can solve the problems of silver nanosheet additive pollution, difficult storage, agglomeration, etc., and achieve the effects of ensuring sample cleanliness, large specific surface area, and new synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

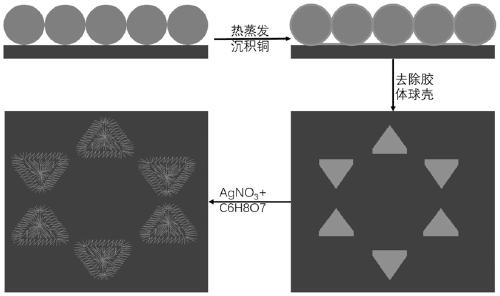

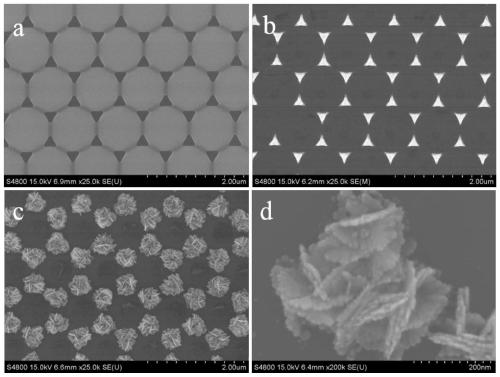

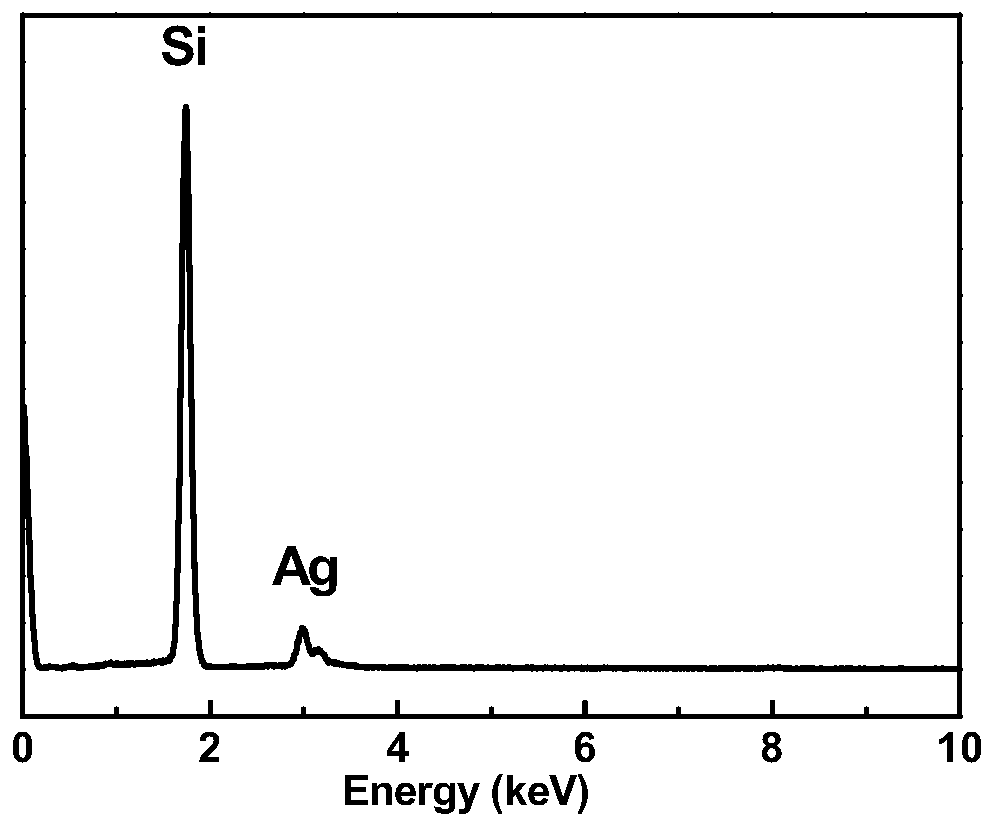

[0033] The detailed process steps are as follows. (1) Using the gas-liquid-solid interfacial self-assembly method reported in the literature, a large-sized single-layer PS sphere colloidal crystal film was prepared on a clean glass slide. That is, PS ball (diameter 1 μm) suspension (2.5wt%) and ethanol are mixed evenly by ultrasound at a volume ratio of 1:1, and a clean glass slide is taken, and an appropriate amount of deionized water is added on top of it to form a large-area water film. About 0.1mL of the ball mixing solution was added to the surface of the water film, and the PS balls spontaneously self-assembled at the gas-liquid-solid interface to form a single-layer colloidal crystal film of several square centimeters. (2) Move the slide slowly at 45 ° After immersing in water, the PS sphere film will separate from the glass slide and float on the water surface. Take the clean silicon wafer and pick it up, and then transfer the PS sphere film to the silicon wafer. (3)...

Embodiment 2

[0039] Other steps and process conditions are identical with embodiment 1. The difference is that in step (3), the PS ball template / silicon chip was etched for different times, namely 0 min, 6 min and 9 min, and the influence of this parameter on the morphology of the silver nanosheet cluster array was investigated.

[0040] Figure 5It is the SEM photos of the copper triangular nanoparticle array (a-c) and the final silver nanosheet cluster array (d-f) obtained corresponding to the three etching times of the PS ball template / silicon wafer. Depend on Figure 5 a-c It can be seen that the size of copper triangular nanoparticles increases with the increase of etching time. Depend on Figure 5 It can be seen from e-f that the size of silver nanosheet clusters gradually increases and finally cross-links together, the density of silver sheets in the clusters increases, and the thickness and size of silver sheets (about 300 nm) increase. According to the growth mechanism of silv...

Embodiment 3

[0042] Other steps and process conditions are the same as in Example 1, the difference is that in step (6), the concentration of silver nitrate in the reaction solution is changed, i.e. 1mM and 100mM, and the concentration of citric acid is constant (50mM). Effect of array shape.

[0043] Figure 6 a and Figure 6 b SEM photographs of products corresponding to two silver nitrate concentrations, respectively. It can be seen that the concentration of silver nitrate is too low, and the silver is not easy to grow into flakes ( Figure 6 a), on the contrary, if the concentration is too high, the reaction will be too intense, which will affect the uniformity of the sample ( Figure 6 b). This indicates that the formation of silver flakes is the result of the growth rate competition of different crystal orientations, which is affected by the reaction rate.

[0044] According to the above experimental results, it can be known that silver nanosheet cluster arrays can be successful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com