Analogue simulation method for flow channel of throwing system of green feed harvester

A simulation method and harvester technology, applied in the field of agricultural machinery, can solve the problems of high research and development pressure, long time consumption, and many materials and personnel, and achieve the effect of reducing the number of trial production rounds, saving test time, and improving calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

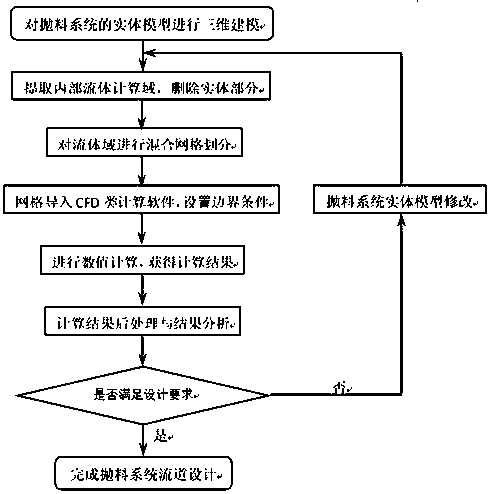

[0023] Such as figure 1 As shown, a flow channel simulation method for the throwing system of a green forage harvester. This implementation includes the following steps:

[0024] (1) Carry out three-dimensional modeling of the solid structure of the throwing system components of the green forage harvester (the main components of the throwing system include the chopping device, throwing shovel and throwing barrel), since the calculation object is the flow channel of the throwing system Therefore, in order to reduce the workload of designers, accurate modeling is not required for the structural parts that do not participate in the flow channel of the ejection system, but for the parts that constitute the flow channel, accurate modeling should be carried out according to the actual design parameters and structural dimensions. The purpose is to provide an accurate calculation model for subsequent flow field calculations.

[0025] (2) Delete the geometric parameters in the model c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com