Oxygen barrier material for PB tube and preparation method thereof and oxygen barrier PB tube

A PB pipe and oxygen barrier technology, applied in the field of plastic pipes, can solve the problems of high difficulty in processing oxygen-proof pipes, increase the wall thickness of pipes, and reduce the oxygen barrier effect, and achieve low cost, avoid defects, and prevent oxygen penetration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

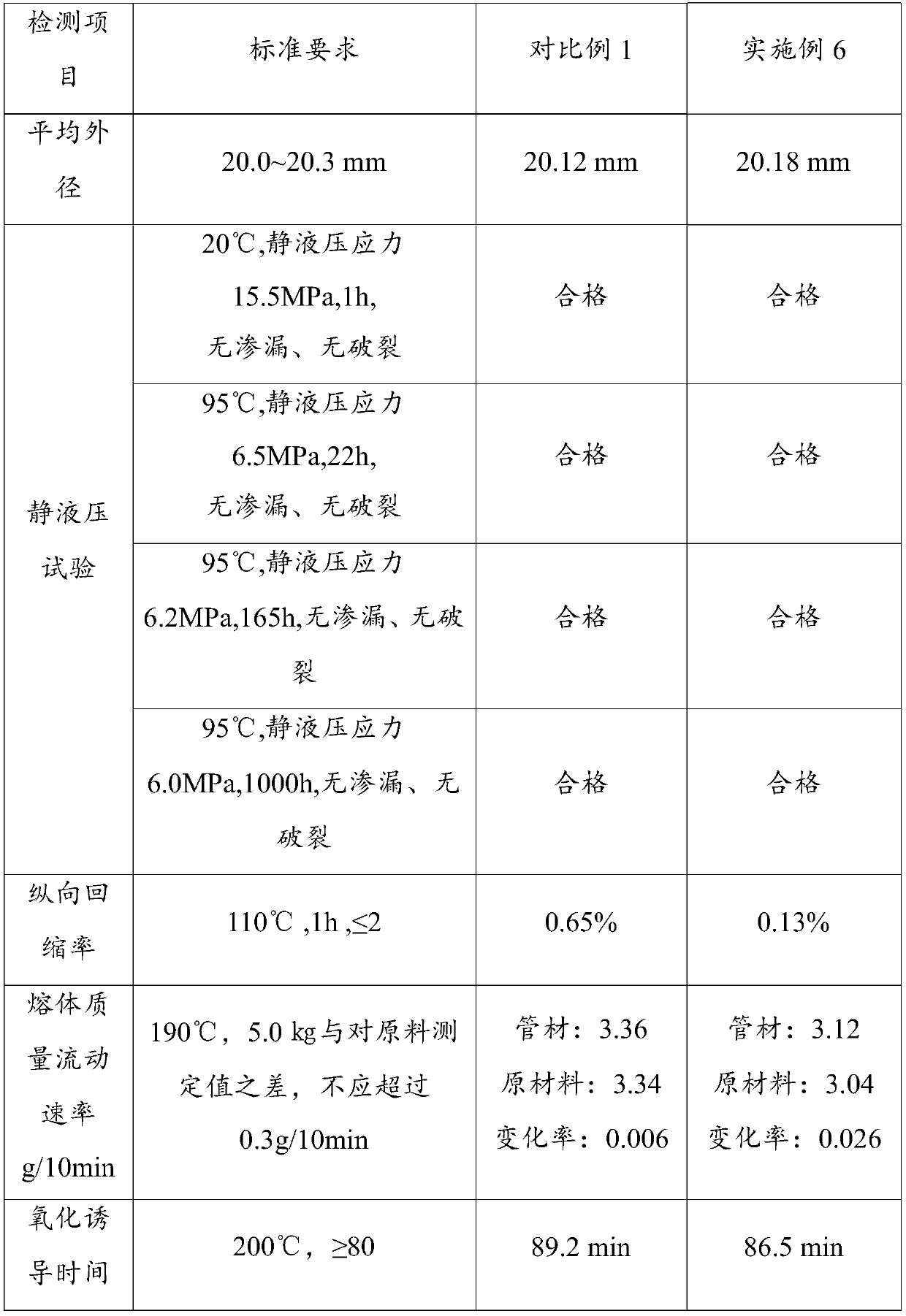

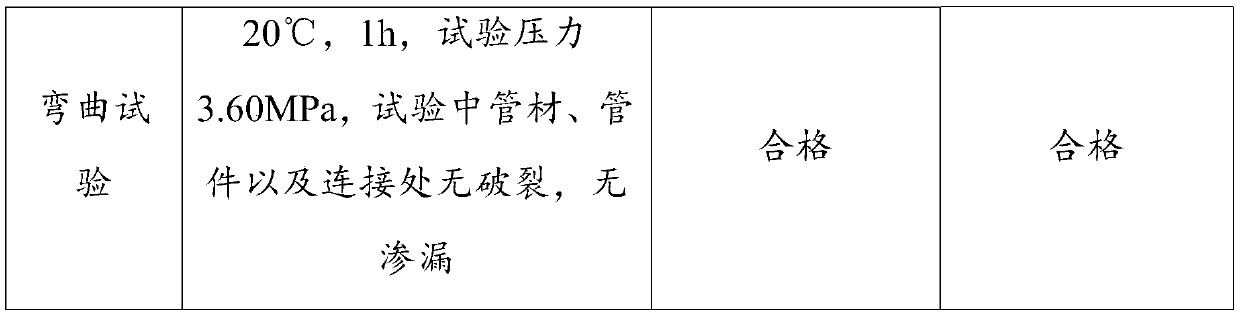

Examples

Embodiment 1

[0028] As an oxygen barrier material for PB pipes according to an embodiment of the present invention, the preparation method of the oxygen barrier material includes the following steps:

[0029] (1) Mix the nano-alumina and the surface modification solution in a high-speed mixer at 50°C for 30 minutes according to the weight ratio of 85:15 to obtain a surface-modified nano-alumina, the surface modification The solution consists of acetone and vinyl tris(2-methoxyethoxy)silane in a weight ratio of 13:87;

[0030] (2) Extrude in a twin-screw extruder after mixing the surface-modified nano-alumina obtained by polybutene, step (1) and zinc stearate as a lubricant. The set temperature of the output cylinder is 130-140°C in zone 1, 140-150°C in zone 2, 150-160°C in zone 3, 160-170°C in zone 4, 170-180°C in zone 5, head temperature: 160-180°C °C to obtain the oxygen barrier material for PB pipes, the weight ratio of the polybutene, the surface-modified nano-alumina obtained in step...

Embodiment 2

[0032] As an oxygen barrier material for PB pipes in an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is: the polybutene, the surface-modified nano-alumina obtained in step (1) and lubricant The weight ratio is 40:30:3.

Embodiment 3

[0034] As an oxygen barrier material for PB pipes in an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is: the polybutene, the surface-modified nano-alumina obtained in step (1) and lubricant The weight ratio is 50:25:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com