Efficient and stable VOCs oxidative degradation pt/ceo 2 -tio 2 Preparation method of catalyst

An oxidative degradation and catalyst technology, which is applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc. problem, to achieve the effect of good application prospects, low catalyst cost, excellent low-temperature catalytic oxidation degradation activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

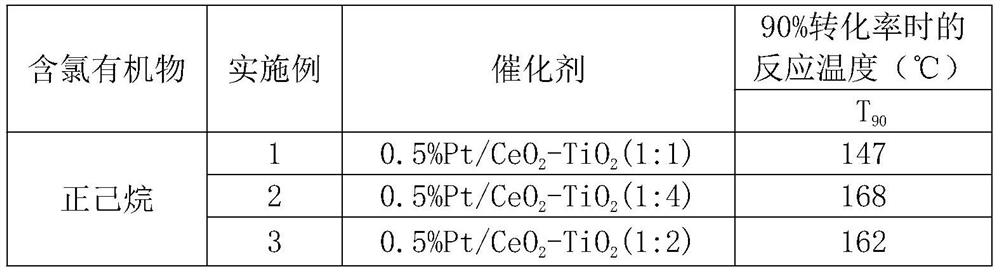

Embodiment 1

[0015] Dissolve 31.4g of cerous nitrate in 200ml of water, add 6.0ml of concentrated hydrochloric acid, stir evenly under ice bath conditions, then add 14.0g of TiCl dropwise 4 solution (concentration is 98%), continue to stir the solution until it becomes transparent, and then add dropwise ammonia water (NH 3 ·H 2 O) until the pH value of the above solution reaches 10.0, leave it at room temperature to age for 12 hours. Then filter, wash with deionized water several times until the filtrate is neutral, dry at 90°C for 12 hours, and roast at 500°C for 2 hours to obtain CeO 2 / TiO 2 CeO with a molar ratio of 1:1 2 -TiO 2 composite oxides.

[0016] 2g of powdered CeO 2 -TiO 2 The composite oxide was dispersed in 200ml of deionized water, after stirring evenly, 1.76g of vitamin C was added, and after stirring for 1 hour, it was washed several times with deionized water. Then add 1ml H 2 PtCl 6 aqueous solution (concentration is 10mgPt / ml), the pH value of the mixed solu...

Embodiment 2

[0018] With the same operation of embodiment 1, the difference is: change the consumption of cerous nitrate into 7.85g, in this catalyst, CeO 2 / TiO 2 The molar ratio is 1:4.

Embodiment 3

[0020] With the same operation of embodiment 1, the difference is: change the consumption of cerous nitrate into 15.7g, in this catalyst, CeO 2 / TiO 2 The molar ratio is 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com