Electrical control system of multi-zone temperature and pressure follow-up control hydraulic machine

A technology of electrical control system and hydraulic press, which is applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables. It can solve the problems of long manufacturing process cycle, prone to cracks, and unqualified products, and achieve saving raw materials. , improve the pass rate, and have strong practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

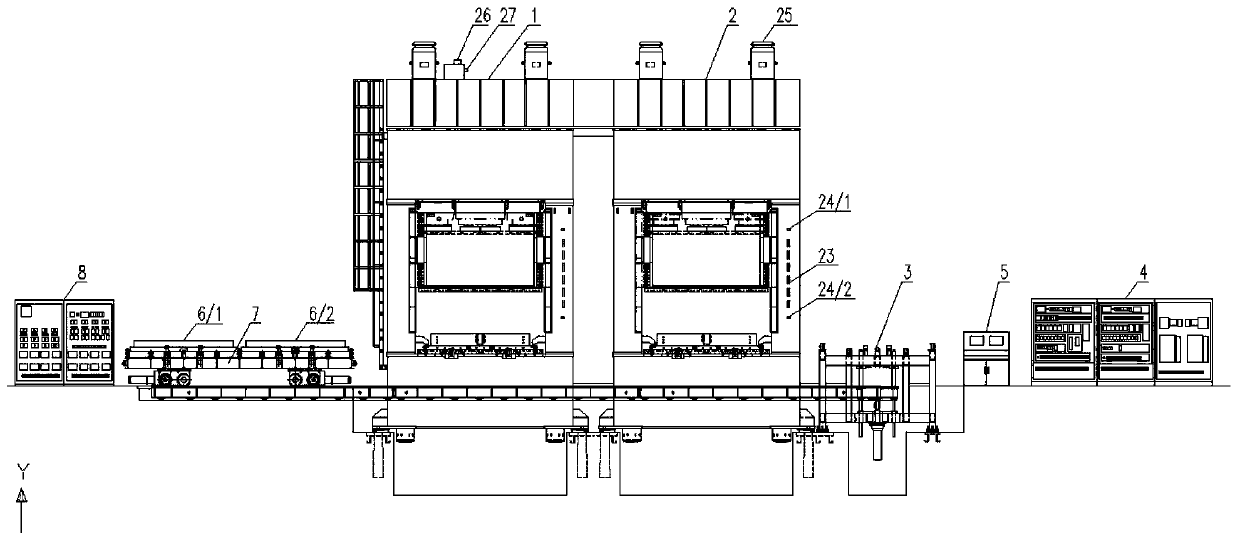

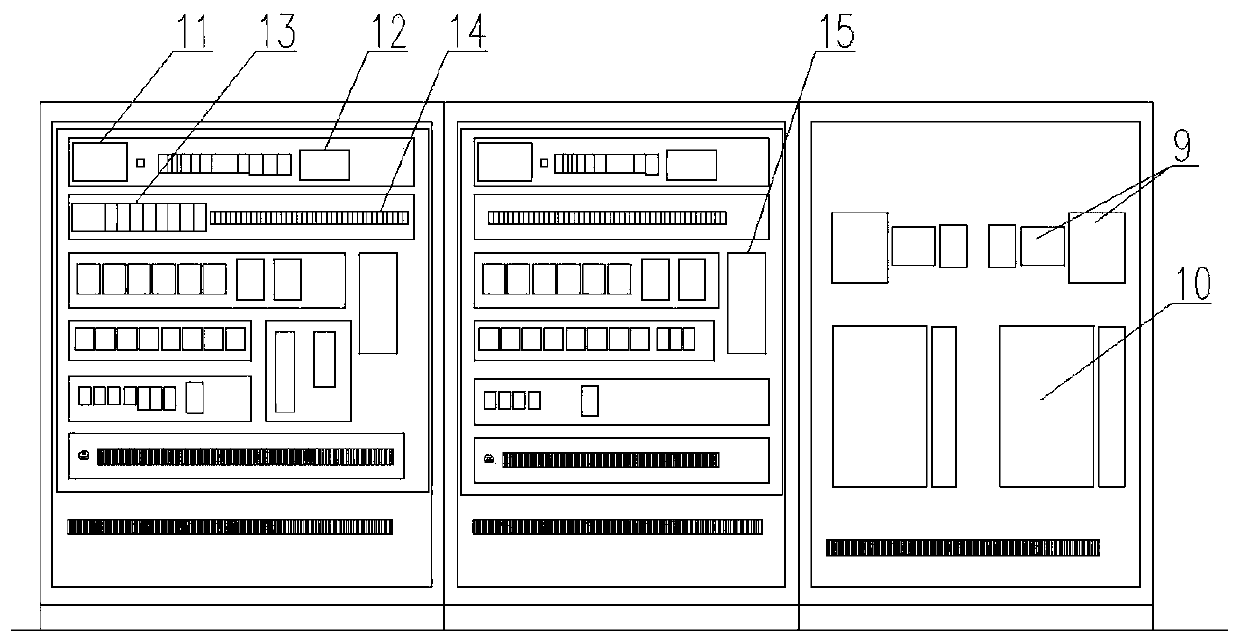

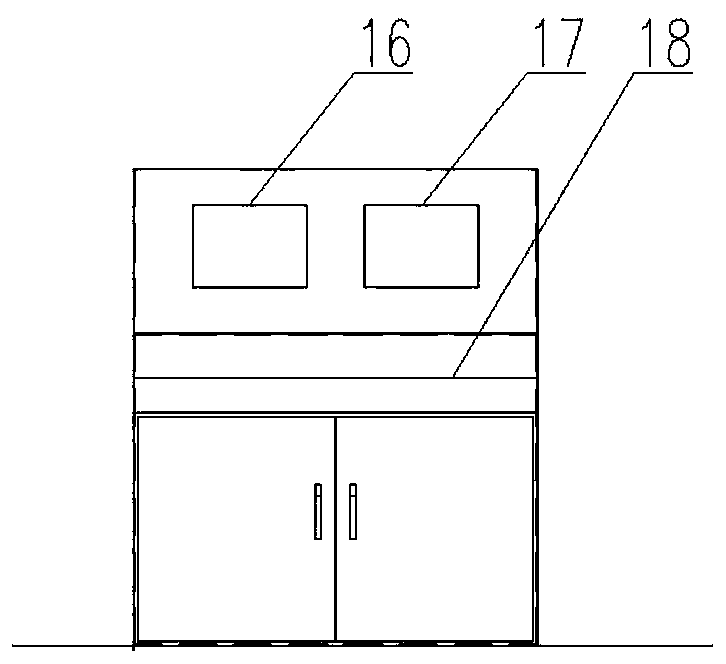

[0054] according to Figure 1-7 The electrical control system of a multi-zone temperature and pressure follow-up control hydraulic press shown includes a hydraulic control electrical cabinet 4, a heating control electrical cabinet 8, an oil cooler, a thermoforming hydraulic press body 1 dedicated to composite materials, and a cooling cabinet dedicated to composite materials. Forming hydraulic press body 2, demoulding hydraulic press body for composite materials, hydraulic station for composite materials hydraulic press, demoulding machine 3, K-type thermocouple, high temperature heating tube, 1# drawing trolley 6 / 1, 2# drawing trolley 6 / 2. Die changing trolley 7, piano-style console 5, centralized operation panel 18, displacement sensor 23, pressure sensor 27, absolute value encoder, characterized in that: the hydraulic control electrical cabinet 4 is equipped with a motor starting circuit 9. Control transformer 11, voltage stabilized power supply 12, servo driver 10, servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com